High capacity rectangular flexible cable and preparation technology thereof

A preparation process and technology of flexible cables, applied in cable/conductor manufacturing, insulated cables, bendable cables, etc., can solve the problems of large bending radius of cables, waste of resources, rising copper prices, etc., and achieve high current carrying capacity, convenient connection, The effect of high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

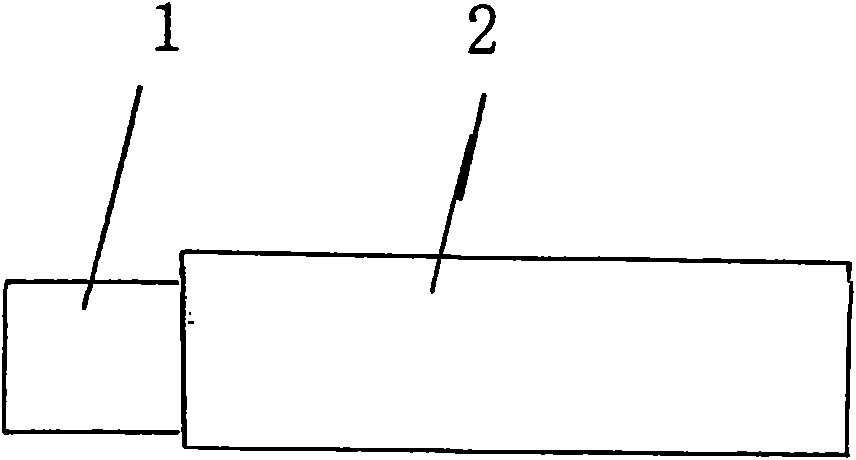

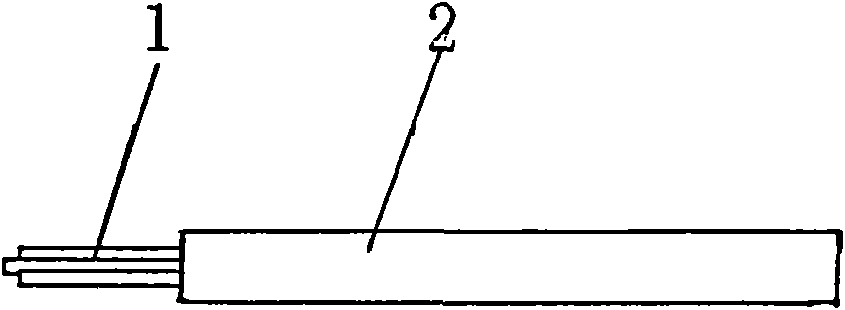

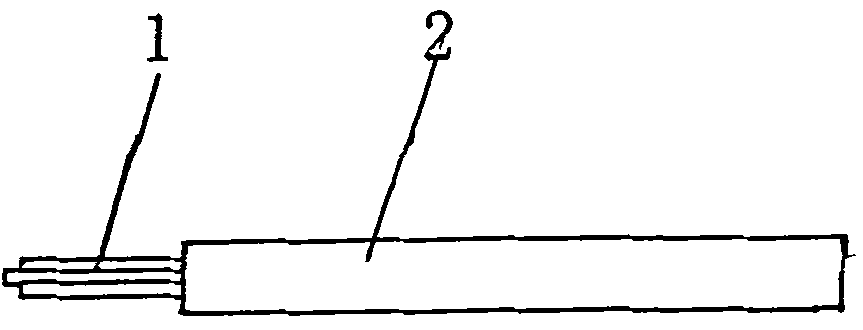

[0010] With reference to the figure, the structure of the high-capacity rectangular flexible cable is that the outer layer of conductor 1 is an insulating layer 2. The conductor 1 is made up of two or more layers of copper bars. The insulating layer 2 is extruded by a cable extruder with a rectangular mold. Out of the insulating material.

[0011] The cable cross section is rectangular or approximately rectangular.

[0012] The preparation process of the high-capacity rectangular flexible cable is characterized by the fact that the laminated copper bar which is superimposed by two or more layers of copper bars adopts a similar ordinary round cable pay-off device, and the conductor 1 is formed by the laminated copper bar. The layer is an insulating layer 2. The insulating layer 2 is made of insulating material extruded by a cable extruder with a rectangular extrusion die. The cross section of the high-capacity rectangular flexible cable is rectangular or approximately rectangular.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com