Light guide plate manufactured by inner carving, manufacture method thereof and lighting lamp

A manufacturing method and technology for lighting lamps, applied in the field of light guide plates, can solve the problems of reduced light guide efficiency, reduced service life, exposed light guide points of the light guide plate, etc., so as to reduce light decay, improve service life, and improve light guide efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

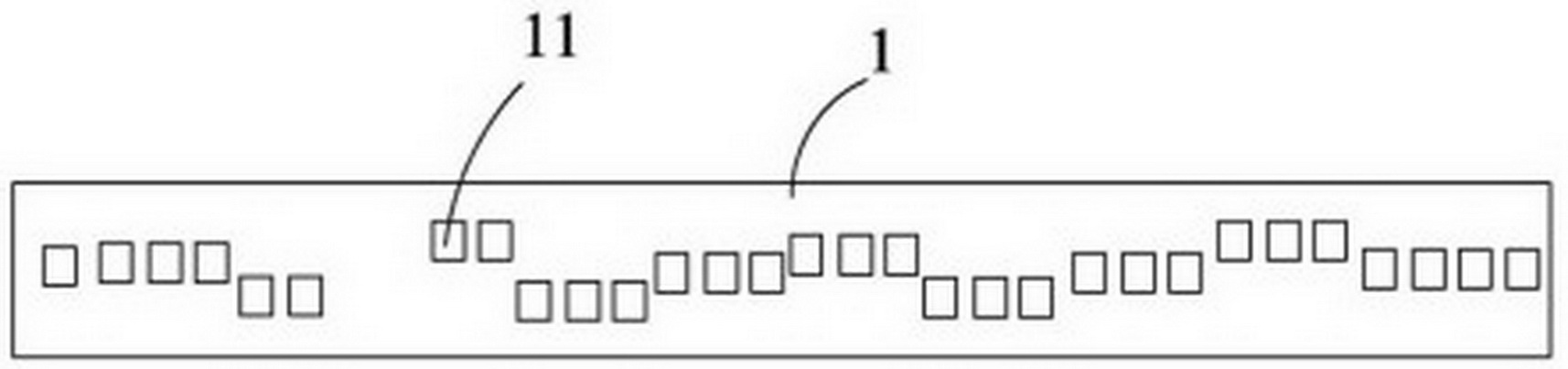

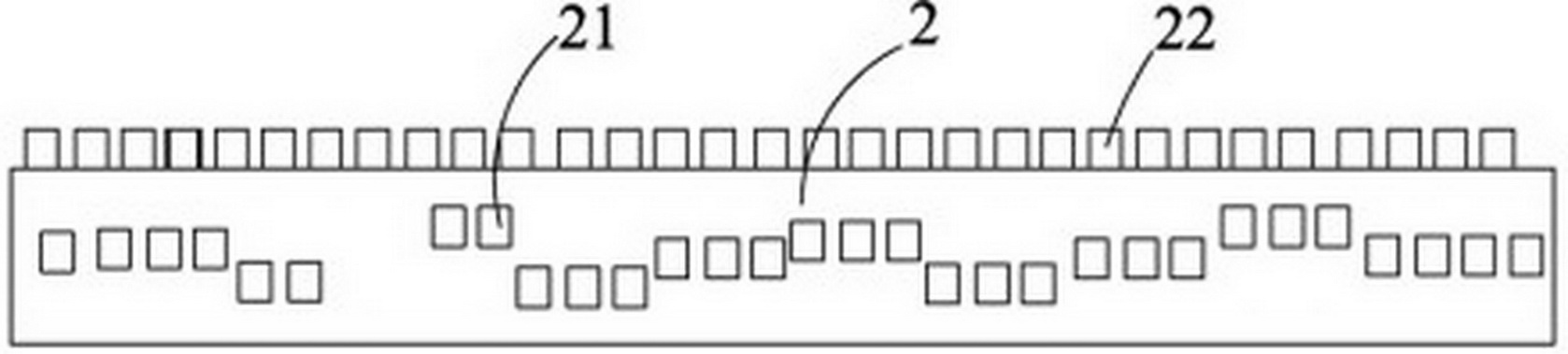

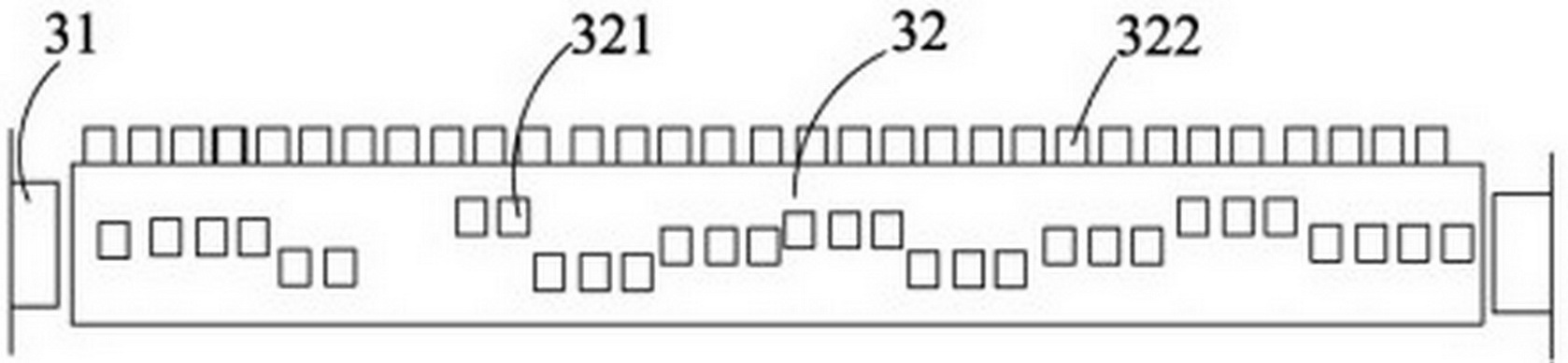

[0019] See figure 1 , the light guide plate 1 made by inner engraving according to Embodiment 1 of the present invention is provided with an inner light guide point 11 inside the light guide plate. Contact with substances that are easy to pollute the light guide point, thereby improving the light guide efficiency, reducing light decay, and increasing the service life of the light guide plate.

[0020] The interior of the light guide plate is engraved with inner light guide points, and the inner light guide points can be carved into light guide points of different shapes, different sizes, different density distributions, and different depth distributions. In this embodiment, a laser internal engraving machine is used to engrave 3D light guide points. Since the design of the light guide points is 3D, the refraction of the 3D light guide points is more uniform and three-dimensional, highlighting the 3D light guide plate with a real three-dimensional effect. The light guide point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com