Method for detecting geometric accuracy of numerically-controlled machine tool based on multi-channel laser time-sharing measurement

A technology of numerical control machine tools and geometric accuracy, which is used in measurement devices, optical devices, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

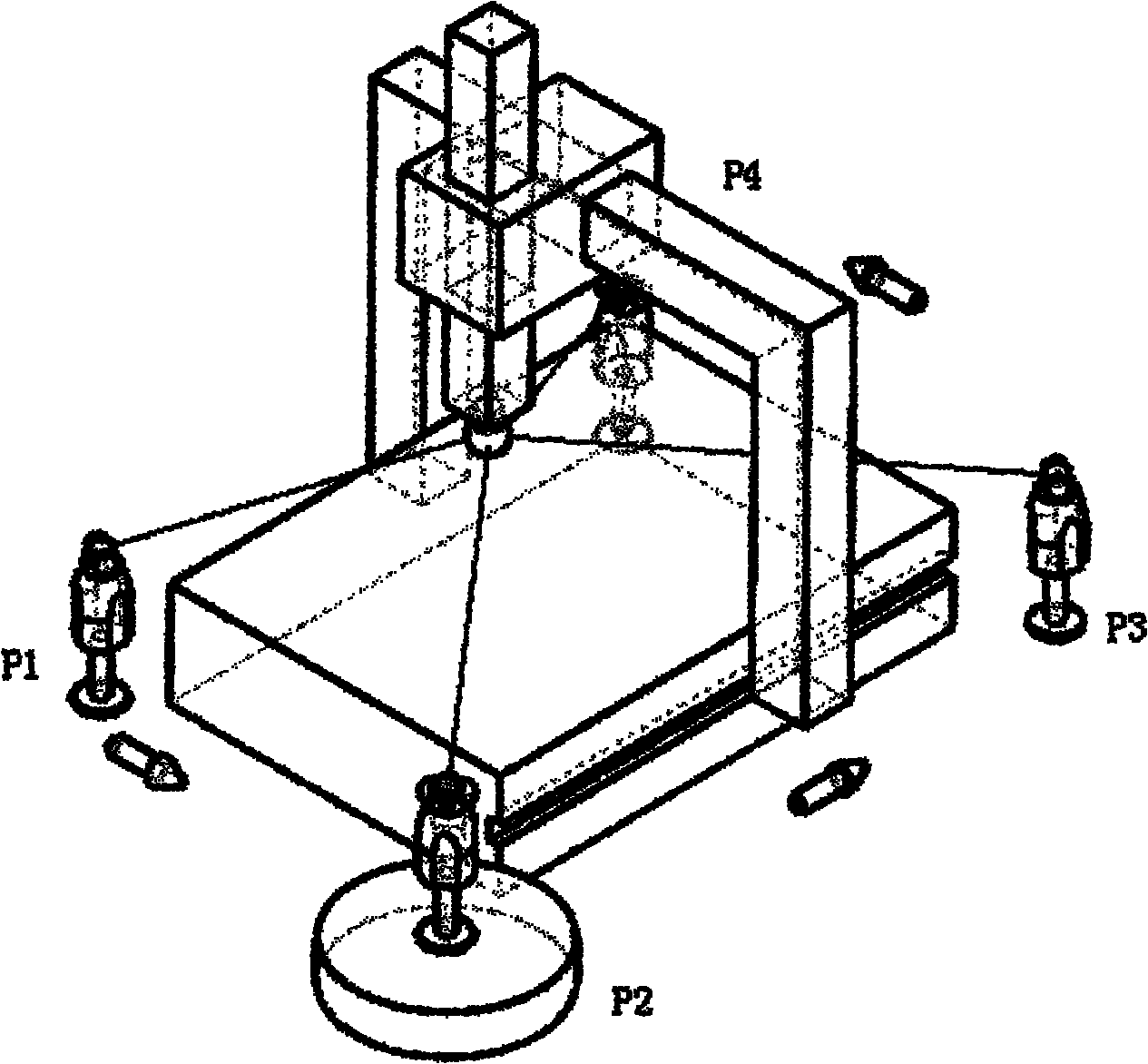

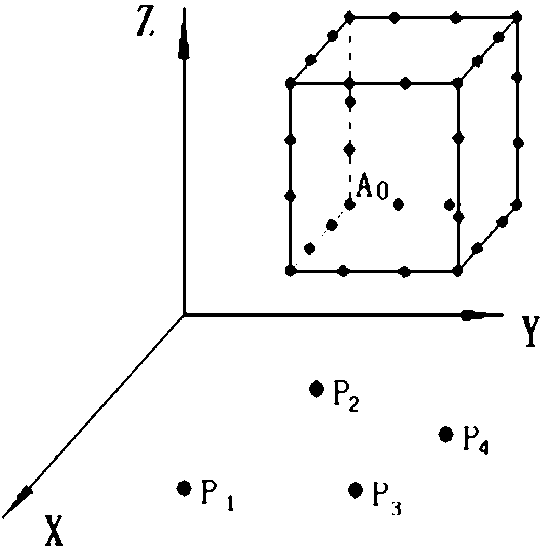

[0047] like figure 1 , figure 2 Shown: a kind of numerical control machine tool geometric accuracy detection method based on laser multi-channel time-sharing measurement, it is characterized in that, comprises the following steps:

[0048] (1) Multi-channel time-sharing measurement steps

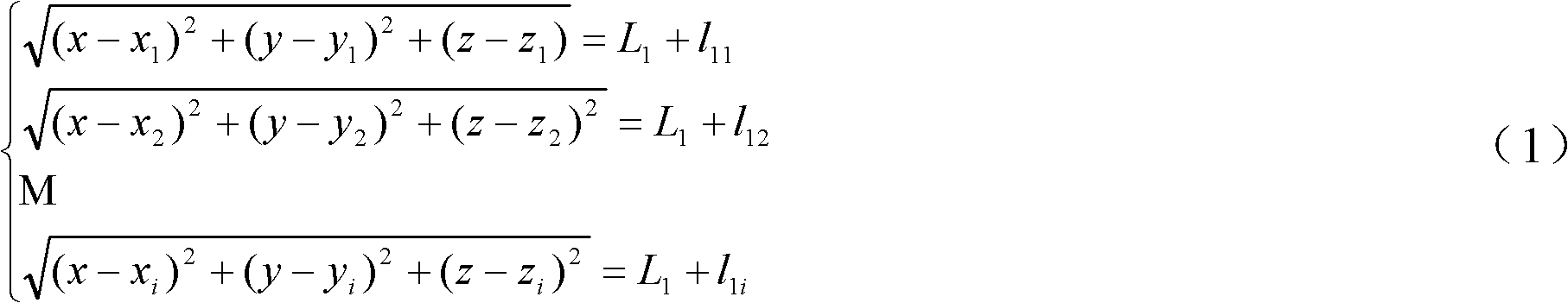

[0049] During the measurement, the machine tool is controlled to feed in three-dimensional space, and four measurement points are set on each side of its cube motion area. A laser tracker measures the same motion trajectory of the machine tool at least three base points successively. When the machine tool moves to the position of each measurement point, the machine tool stops moving, and the distance reading of the laser tracker at the position of the measurement point is recorded. After all the measurement points are measured, the distance measurement readings of the laser tracker at different measurement points are obtained. ; Then move the laser tracker to other base point positions, r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com