Method for mounting water beam of walking beam heating furnace in thermal state

A technology of walking heating furnace and installation method, which is applied in the direction of lighting and heating equipment, furnace, furnace type, etc., can solve the problem of increasing the investment cost of heating furnace, energy waste, failure to ensure positive pressure of water beam and its column, and difficult Guarantee the verticality of the water beam column, etc., to achieve the effect of good centering size, guaranteed verticality and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

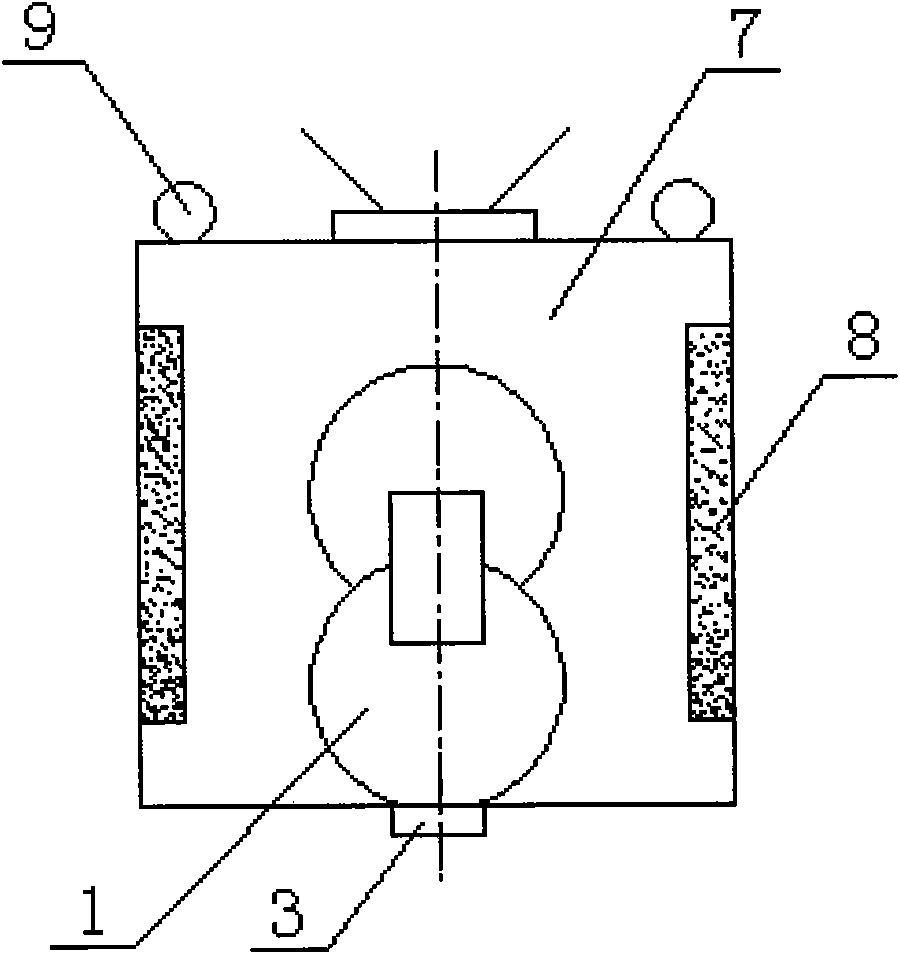

[0025] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0026] The hot-state installation method of the water beam of the walking heating furnace uses the heating insulation box and the temperature control system to completely simulate the welding method of the water beam and the column at 273±10°C. The operation steps are as follows:

[0027] 1) Accurately measure the height Δh between the upper beam of the water beam 1 and the tee opening 3, and determine the upper top elevation a of the double pipe 3# column 2 according to the drawings, and confirm that the verticality of the 3# column is within ±1.0mm, and the elevation is at After the deviation is within the range of ±1.0mm, weld the 3# column 2 with the upper support plate 4 and the lower support plate 5;

[0028] 2) Calculate the thermal elongation of the water beam 1 between each tee opening, x=L*λ, where λ is the expansion coefficient, and L i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com