Connection method of high-rise steel structure steel column base and bottom plate reinforcing steel bar

A technology of steel bar connector and steel structure, which is applied in the direction of building structure and construction, etc., can solve the problems such as the inability to realize the twisting of two sleeves and the difficulty of straight line connection of steel bars.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the drawings and embodiments.

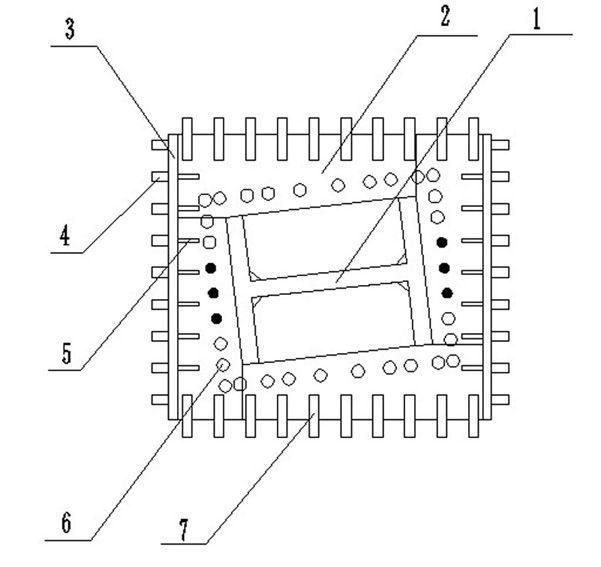

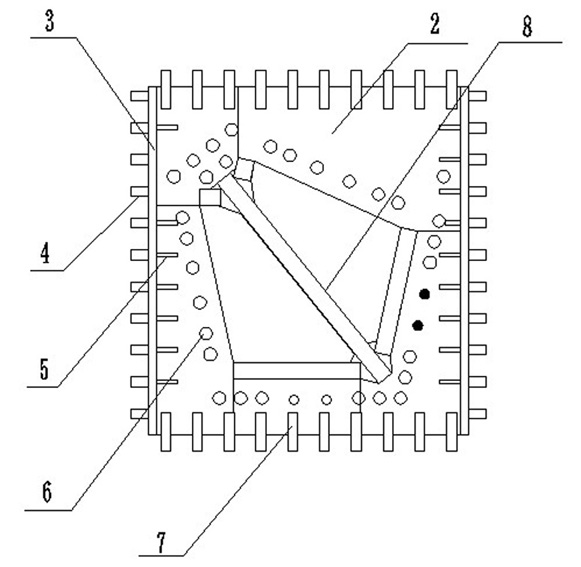

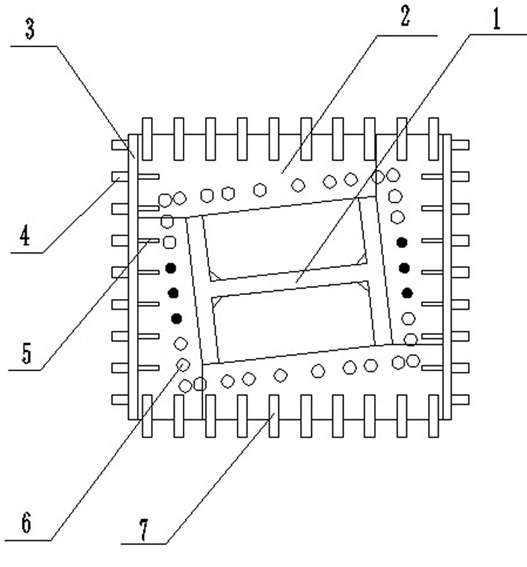

[0020] See figure 1 , The steel column in the figure is the H-shaped steel column 1. By adding a stiffening ring plate to the column foot of the H-shaped steel column 1 and welding steel bar connectors, the foundation steel bar and the steel column foot can be effectively, simply and reasonably connected. Proceed as follows:

[0021] ① Welding procedure qualification in the factory: According to the material of the ring plate 2 and the steel connector 4, the corresponding welding procedure qualification is carried out to ensure the reliable connection of the ring plate 2 and the steel connector 4 with the H-shaped steel column 1.

[0022] ② Weld the stiffening ring plate and the steel bar connector 4 in the factory, and protect the internal thread head of the steel bar connector 4. First, weld the horizontally arranged stiffening ring plate on the outer circumference of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com