Hoisting process for rotating wheel of vertical shaft axial flow hydraulic turbine

An axial-flow, water-turbine technology, applied in the direction of hoisting device, hoisting device, etc., can solve problems such as troublesome use and poor working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

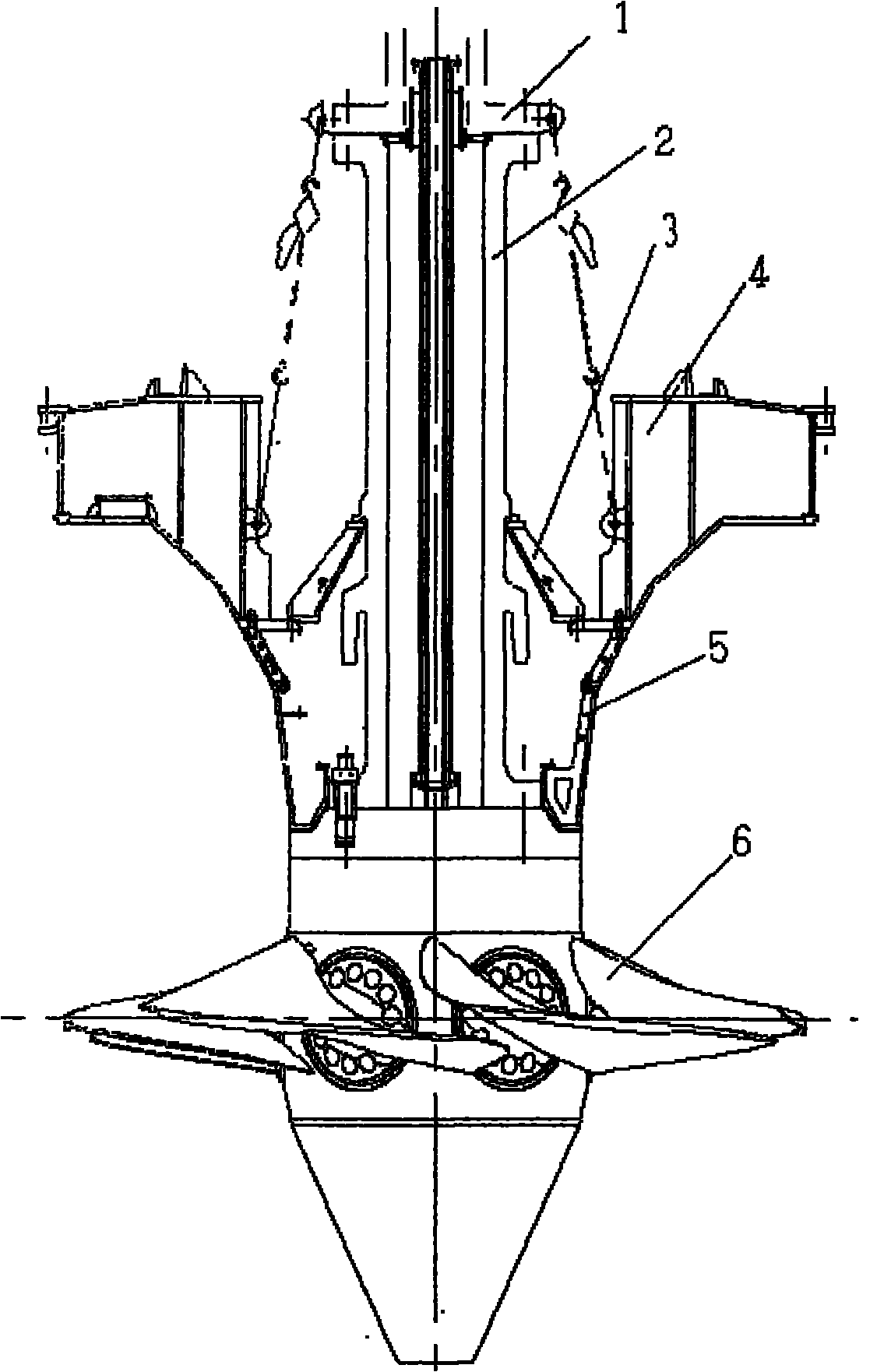

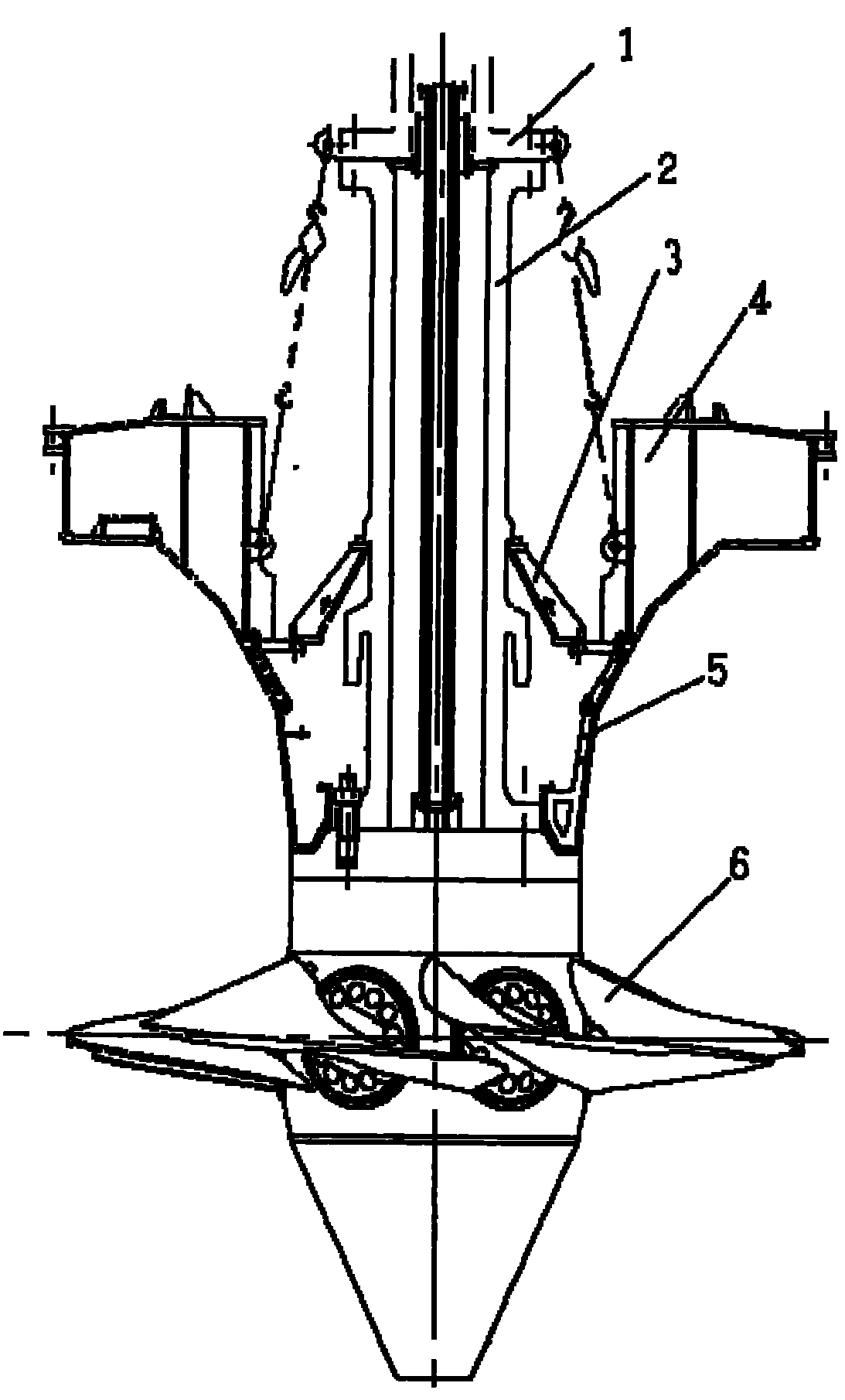

[0009] Further explain below in conjunction with accompanying drawing:

[0010] Such as figure 1 As shown in the figure, the runner hoisting process of the vertical shaft axial flow turbine, put the installed runner 6 on the platform, and the blades are in the fully closed position; Connect the operating oil pipe with the operating oil pipe of the runner, then connect the main shaft with the runner, and pre-tighten the connecting bolts of the runner; 3. Combine the support cover 4 and the diversion cone 5 and insert them into the main shaft or the support cover 4 and the diversion cone 5 Put them in respectively and put them together, and place them on the upper flange of the runner body or on the runner cover. There are snap rings in half; 5. Use a gourd to adjust the upper and lower heights of the combination of the support cover 4 and the diversion cone 5, which is convenient for coupling, and at the same time plays a role of safety protection when the whole is hoisted in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com