Peanut combined harvester

A combined harvester and peanut technology, which is applied to excavator harvesters, harvesters, agricultural machinery and implements, etc., can solve the problems of unreasonable design and high fruit drop rate, and achieve the effect of reducing fruit drop rate and fruit drop rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

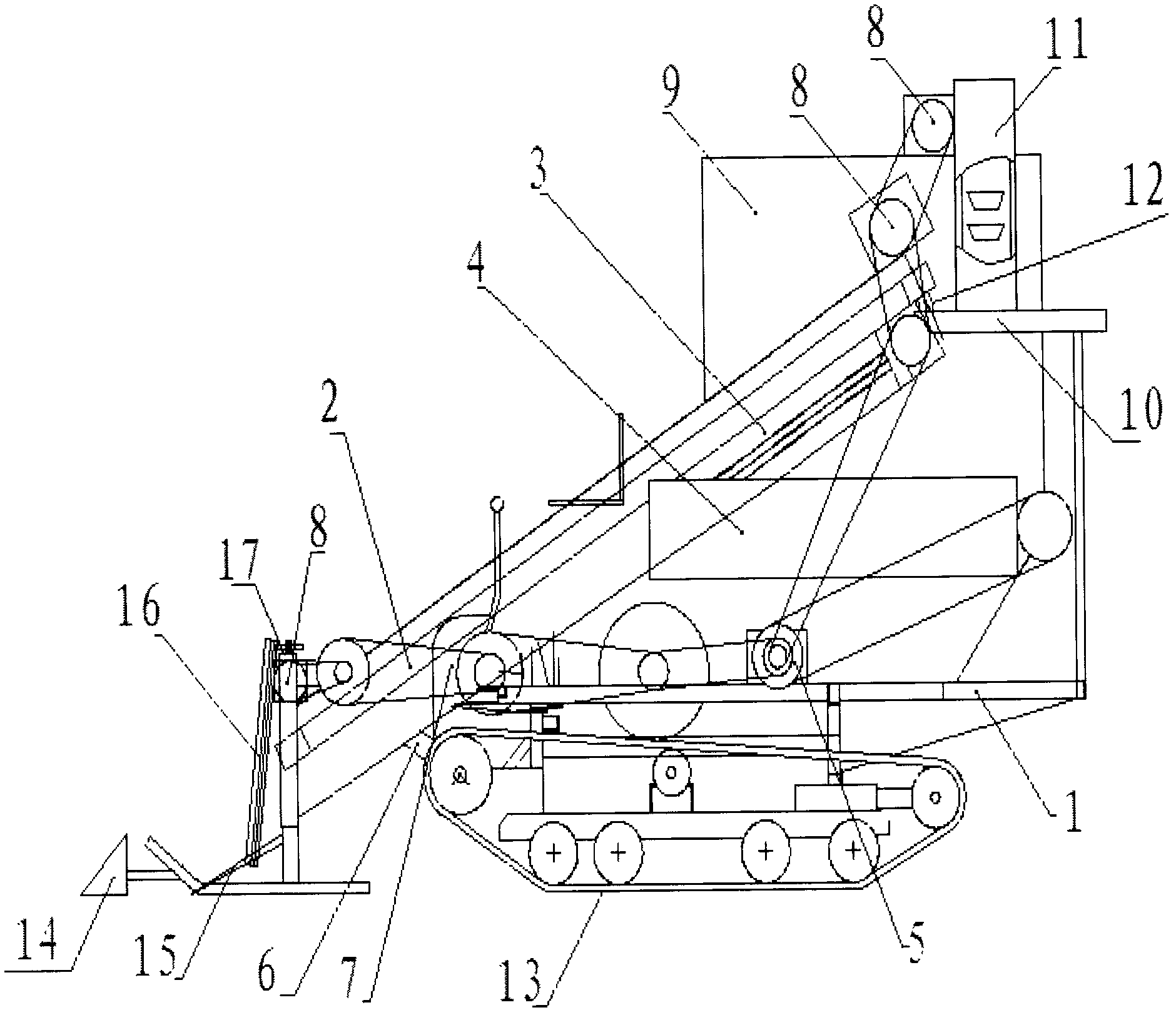

[0009] Attached below figure 1 , the present invention is described in detail as follows:

[0010] The invention discloses a peanut combine harvester, which comprises a frame 1, and an excavating mechanism, a clamping and conveying system 2, a fruit picker 3 and a cleaning screen 4 are sequentially arranged on the frame 1 from front to back. 1 is also equipped with a clutch 5, a hydraulic lifting system 6, a gearbox 7, a steering gearbox 8, a fruit collection box 9, a seedling thrower 10, a lifter 11 and a universal joint 12. In addition, the bottom of the frame 1 A crawler chassis running mechanism 13 is provided. Described excavating mechanism comprises seedling separating device 14, digging shovel 15, seedling supporting device 16 and depth adjustment mechanism 17.

[0011] During specific use, when the peanut combine harvester enters the field work, the hydraulic lifting system 6 is lowered, and the external power is transmitted to each part of the machine through parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com