Pull-type apple picking system and picking method

A traction-type apple-picking technology, which is applied in the traction-type apple picking system and the field of picking, can solve the problems of low manual picking efficiency, increased production cost of orchard industry, backward management methods, etc., achieve good adaptability and passability, and improve picking operations Efficiency, a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementations.

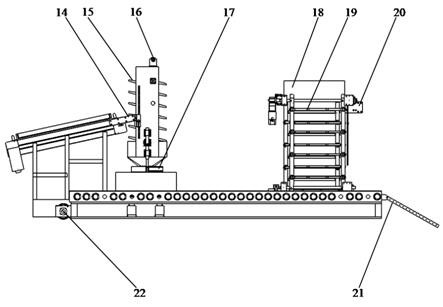

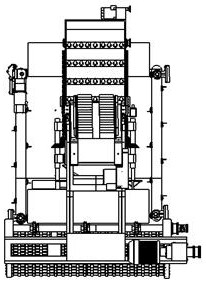

[0018] like Figures 1~6 As shown, a traction type apple picking system of the present invention includes a frame 1, and a conveying device, a roller transmission device 12, a box changing device and a box drop device 21 installed on the frame 1. The rack 1 of the picking system It is fixed on the chassis of the vehicle, and the traction head of the front vehicle provides traction, and the installation position of the picking robotic arm is reserved at the position 1 of the frame 1 on both sides of the front end of the conveying device.

[0019] The conveying device includes a lateral collecting conveyor belt 5 and a vertical vertical conveying belt 6 , and the lateral conveying belt 28 of the collecting conveyor belt 5 is driven by the collecting conveying motor 2 . The collection conveyor belt 5 is transported obliquely upwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com