Apple conveying and boxing mechanism

A technology for apples and conveyor racks, applied in the field of agricultural machinery, can solve problems such as economic loss, apple collision damage, and high labor intensity, and achieve the effects of reducing collision damage, avoiding rolling collision, and simple mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

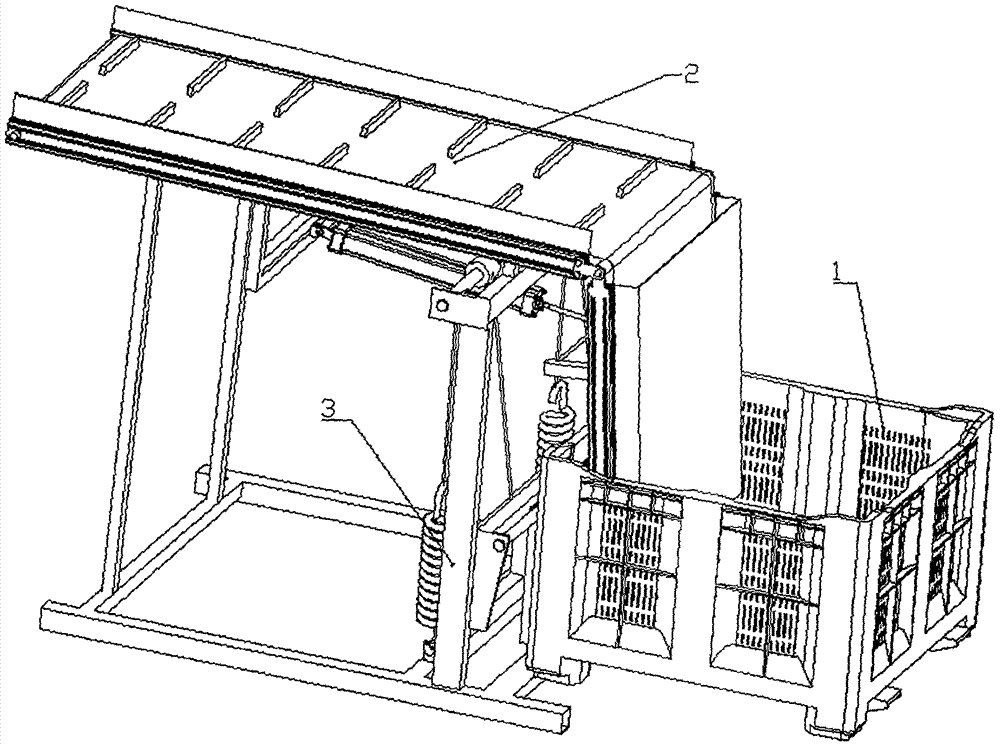

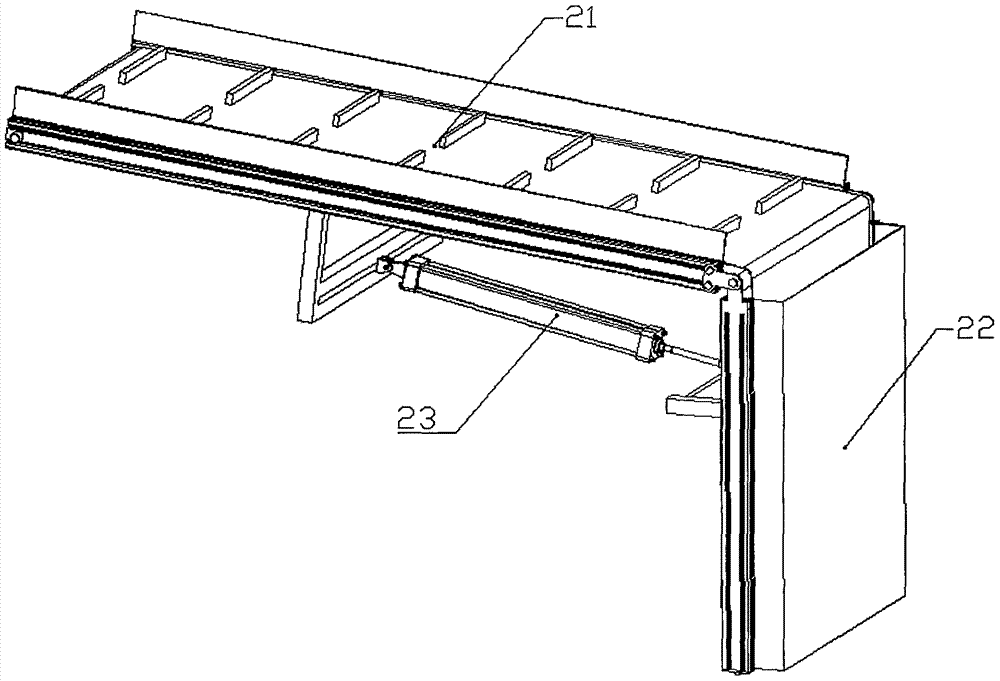

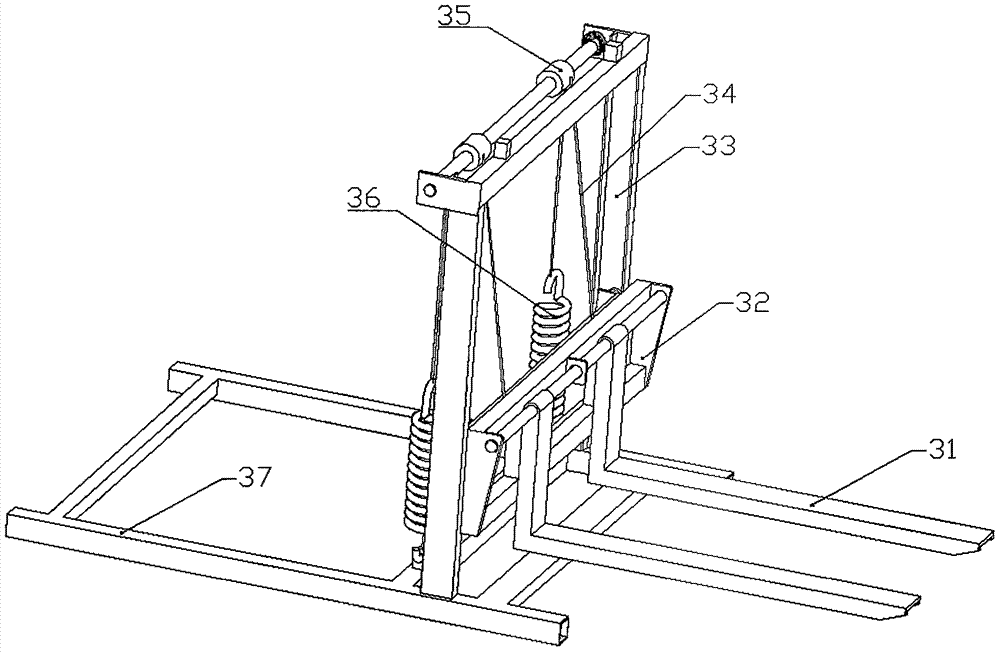

[0013] Attached below figure 1 , attached figure 2 , attached image 3 The present invention is described further:

[0014] Apple transmission and boxing mechanism mainly include fixed transmission frame 21, moving transmission frame 22, cylinder 23, box frame 31, lifting frame 32, chute 33, steel rope 34, belt pulley 35, spring 36, base 37. It is characterized in that: the fixed transmission frame 21 is fixedly connected to the base 37 and the top beam of the chute 33, the moving transmission frame 22 is connected to the fixed transmission frame 21 through a hinge, and the cylinder body of the cylinder 23 is connected to the fixed transmission frame through a hinge. On the transmission frame 21, the piston rod of the cylinder 23 and the moving transmission frame 22 are also connected by hinges. The chute 33 is welded on the base 37, the pulley 35 is mounted on the top of the chute 33 through a shaft and a bearing, the steel rope 34 goes around the pulley 35, one end is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com