Machine tool having a carrier device for work pieces or tools

A technology for machine tools and workpieces, applied in the field of machine tools with carrier devices for workpieces or tools, can solve problems such as high space requirements, and achieve the effect of simplified structure and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

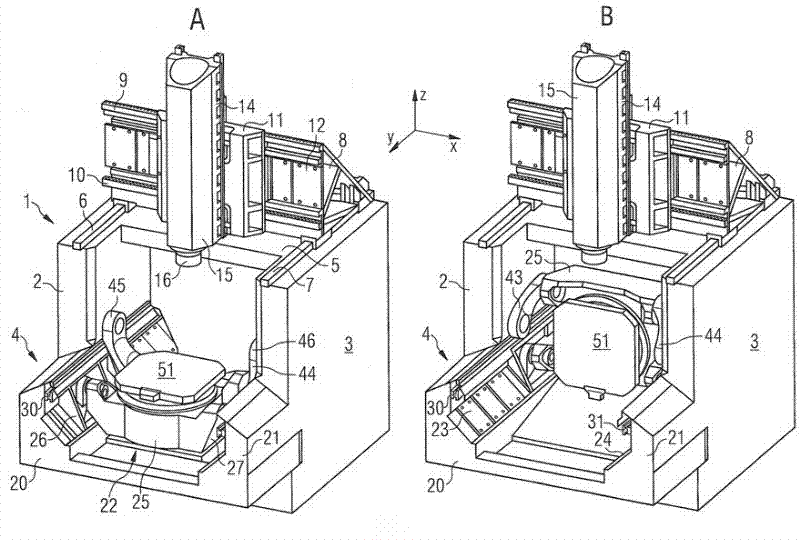

[0025] figure 1 The milling machine illustrated in middle perspective is executed as a crane frame and contains a highly rigid frame 1 formed by two side walls 2 , 3 parallel to each other, a front section 4 and an upper cover 5 . On the top faces of the two side walls 2, 3, guide rails 6, 7 are installed in an orientation parallel to each other, on which guide rails 6, 7 guide the transverse support 8 so that it can be moved by the motor in the direction of the Y coordinate axis shift. On the vertical front side of this transverse support 8 two guide rails 9 , 10 are mounted at a vertical distance, in which guide rails 9 , 10 the horizontal support 11 is guided so as to be displaceable in the direction of the X coordinate. An electric linear motor 12 arranged between the two guide rails 9 , 10 is used as drive for the horizontal support 11 . On the front side of the horizontal support 11 a vertical support 14 is mounted so as to be displaceable in the Z coordinate axis, whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com