Multi-contact high current elastic contact element terminal

An elastic contact, high current technology, applied in the direction of contact parts, etc., can solve the problems of unsatisfactory heat dissipation effect, large volume and high material cost in the contact area, so as to improve the current carrying capacity and connection reliability, and increase the area of the contact area. , the effect of the expansion of the conductive cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

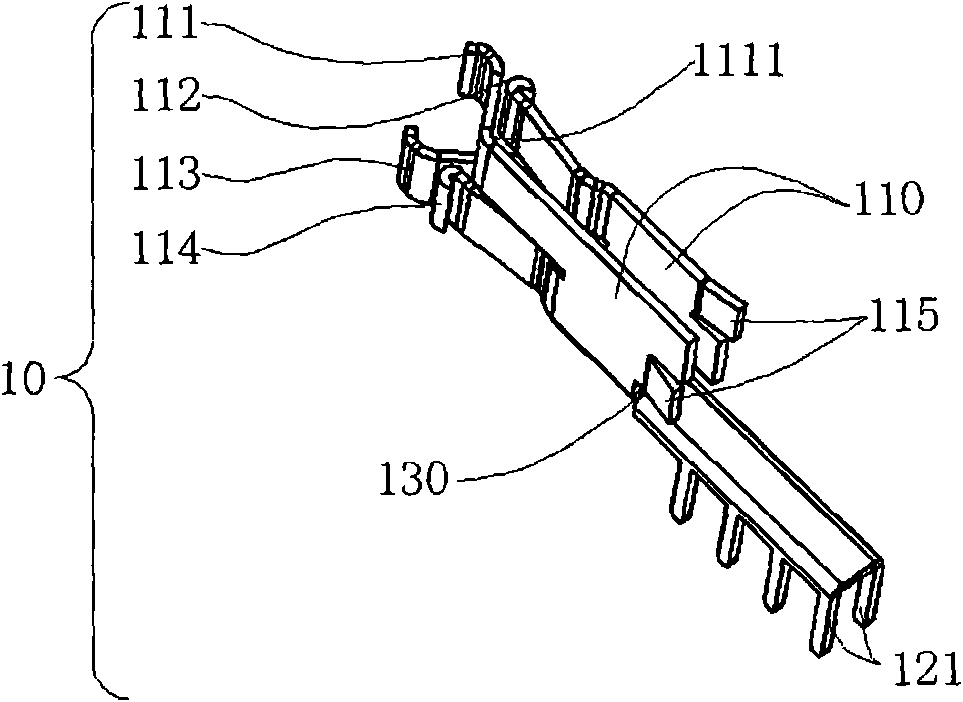

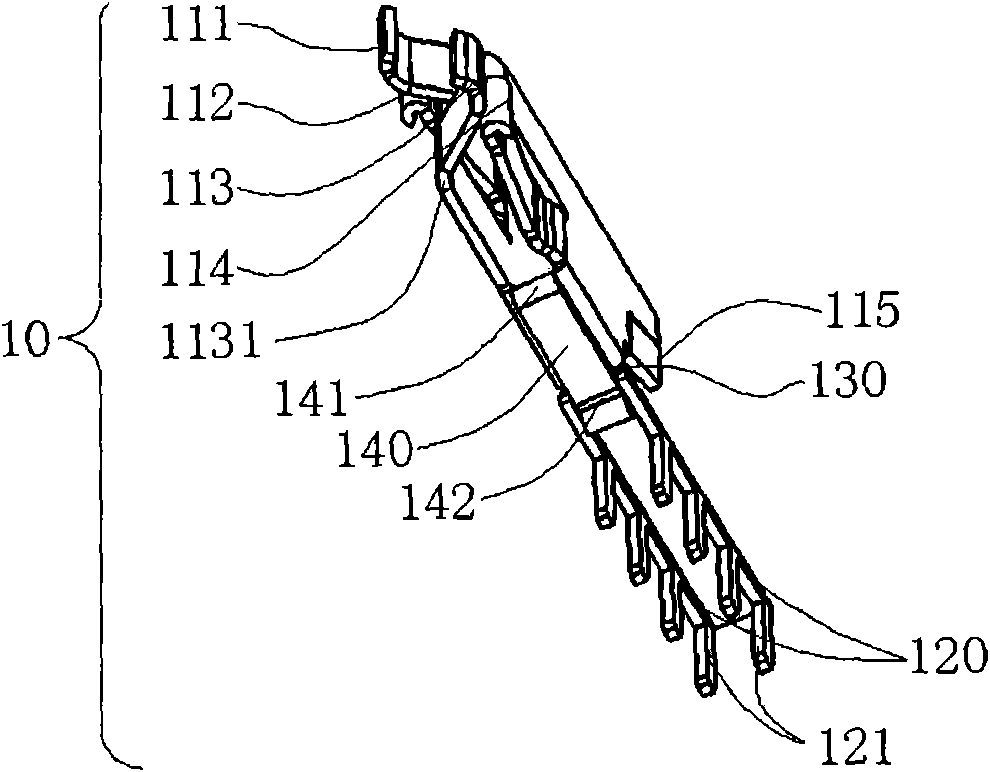

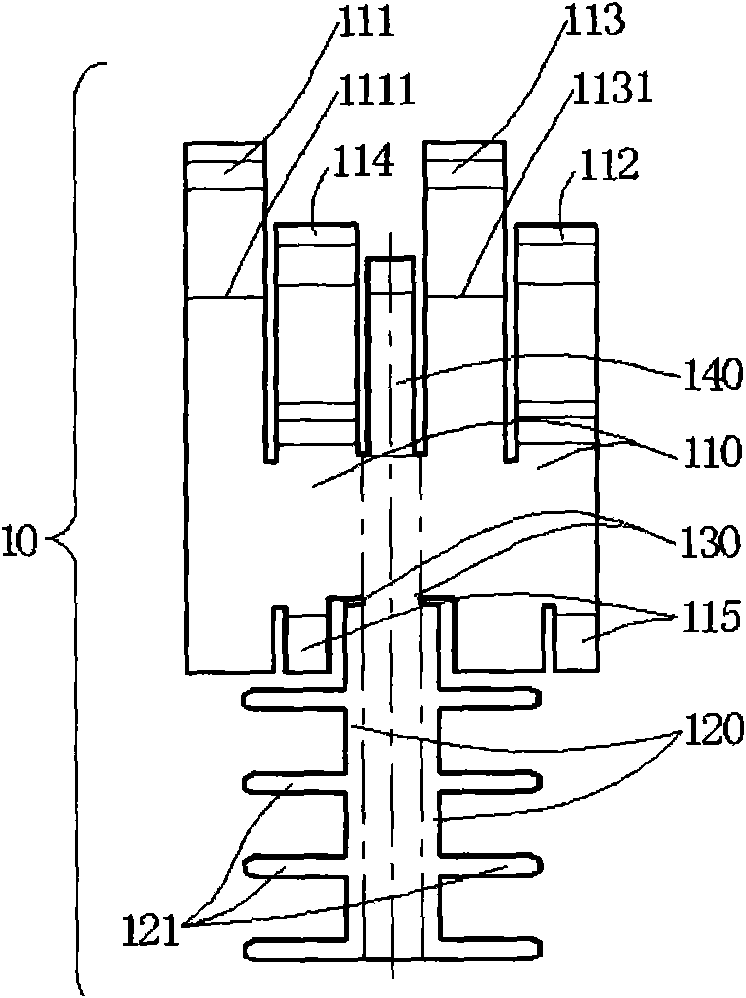

[0017] Example: such as figure 1 , figure 2 As shown, a multi-contact high-current elastic contact terminal includes a butt end area 110 and a terminal connection area 102 .

[0018] The butt end region 110 includes four contact regions: a long one contact region 111 , a short two contact region 112 , a long three contact region 113 and a short four contact region 114 . The root of the long one contact region 111 and the root of the short four contact region 114 are located on the same side of the butt end region 110, and the root of the long one contact region 111 and the root of the short second contact region 112 are correspondingly distributed on both sides of the butt end region 110, The first long contact region 111 turns to distribute on the same side as the second short contact region 112 , and together with the second short contact region 112 forms a right contact region. The roots of the long three contact regions 113 and the roots of the short second contact regi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com