Steplessly adjustable electric control gas valve

A technology of stepless adjustment and gas valve, applied in the direction of valve details, multi-way valves, valve devices, etc., can solve the problem of inaccurate fire control of cock valves, and achieve the effect of precise control of fire power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

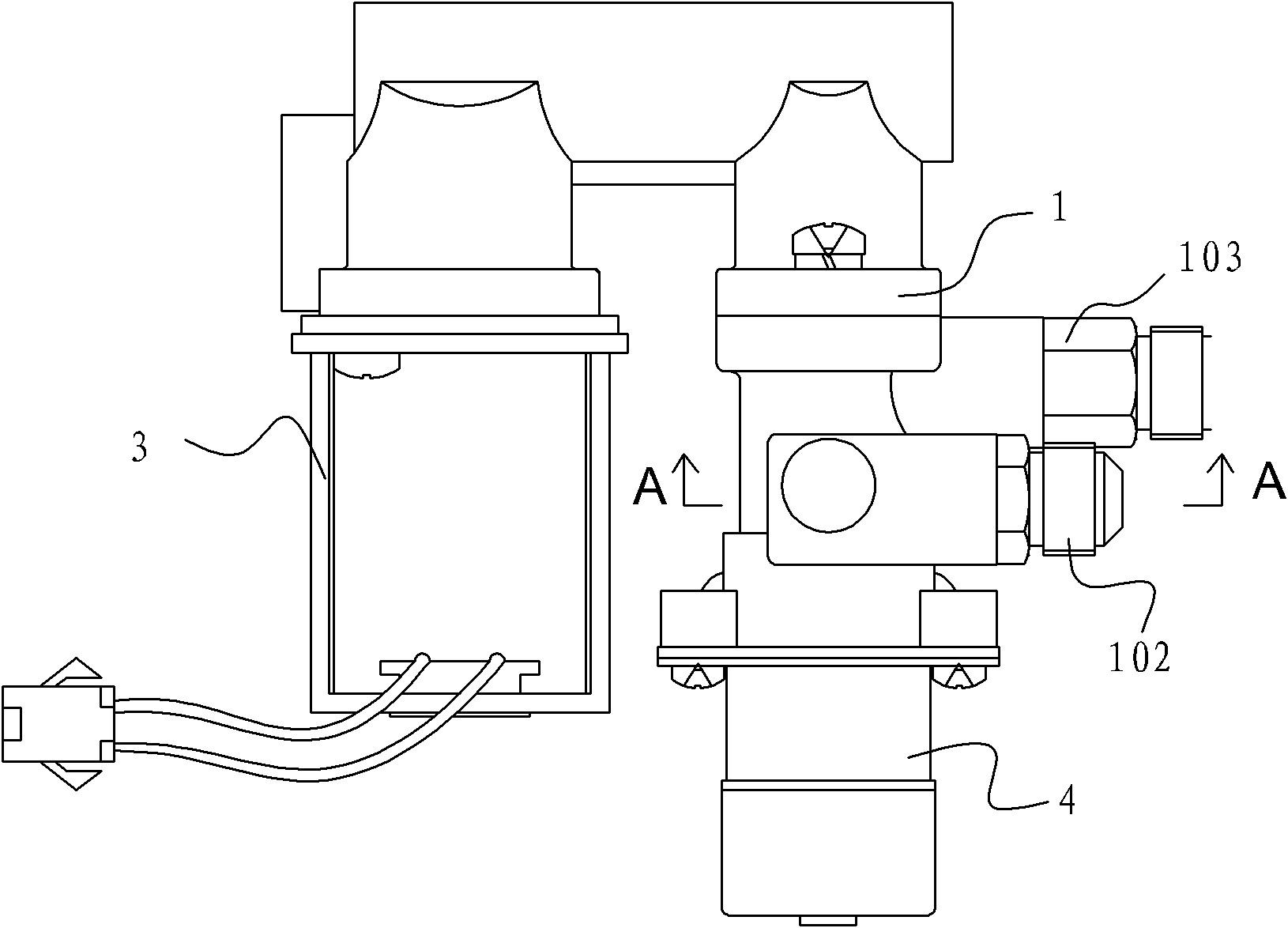

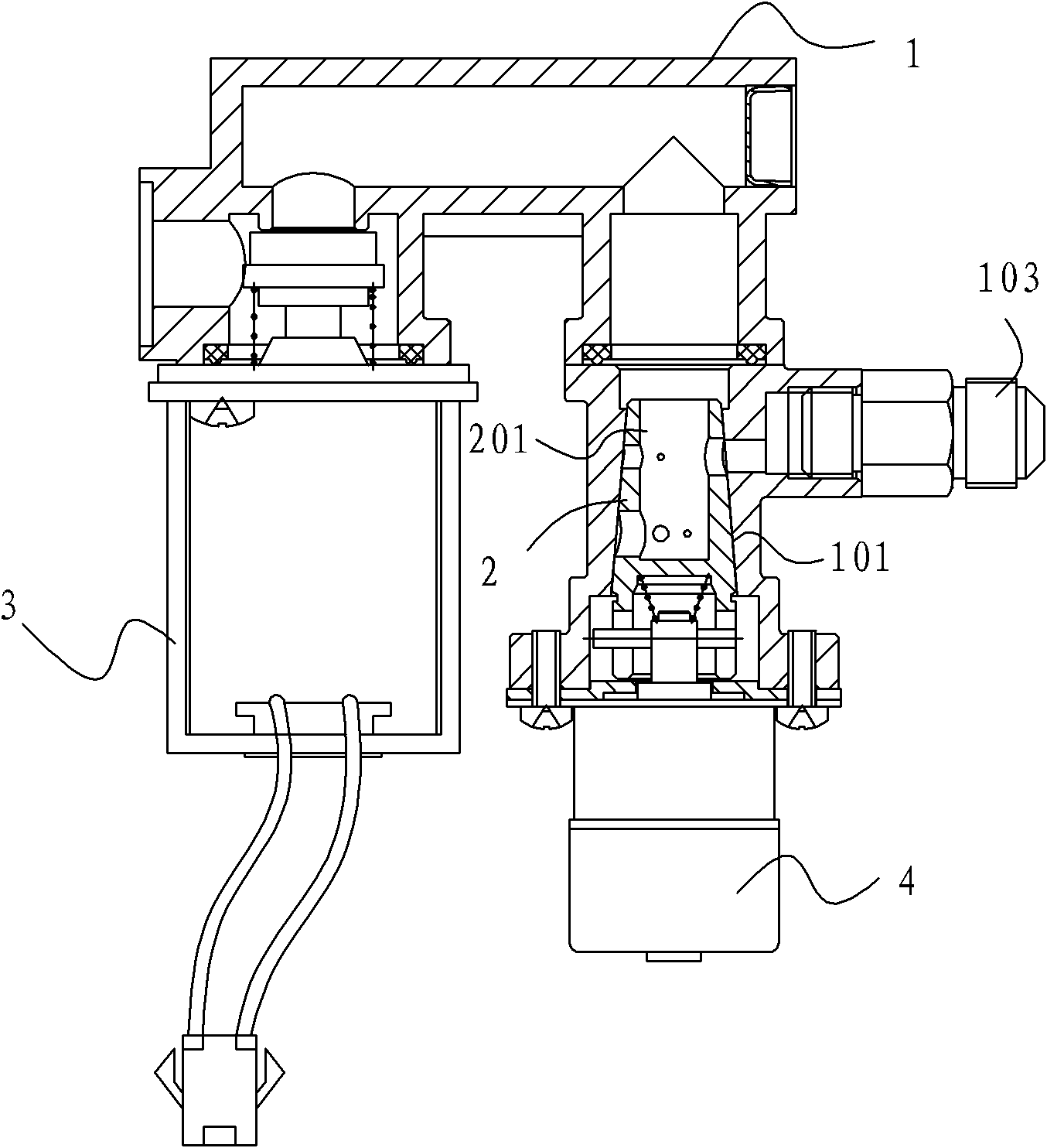

[0021] As shown in the figure, a stepless regulating cock valve includes a valve body 1, an air inlet, an air outlet pipe 102, and an air outlet pipe 103 are arranged on the valve body 1, and a solenoid valve 3 is installed at the air inlet, and inside the valve body 1 A cock hole 101 is provided, and a spool 2 cooperating with it is arranged inside the cock hole 101 , and the spool 2 is driven by the motor 4 installed on the valve body 1 .

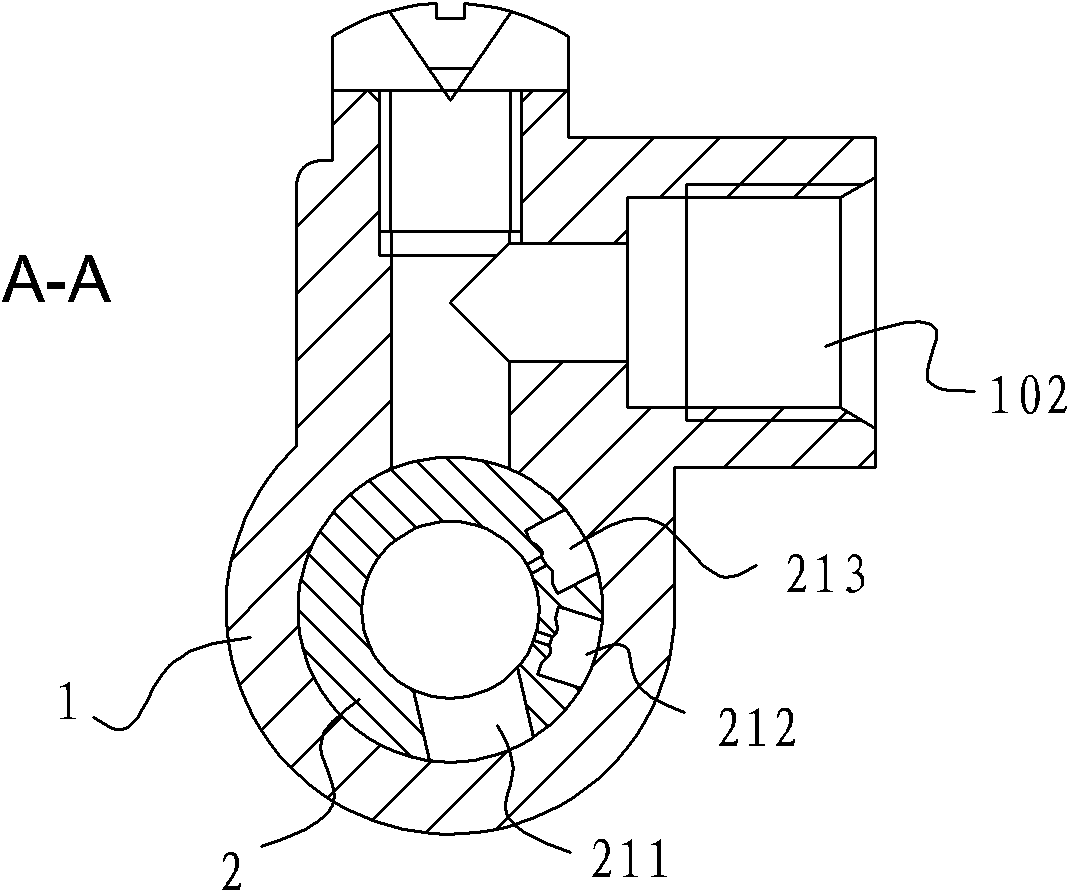

[0022] The inner wall of the valve body 1 is provided with an air inlet 111 and an air inlet 112, and the valve core 2 is provided with an axially arranged central hole 201. One end of the central hole 201 is connected to the drive shaft of the motor 4 and is closed, and the other end is connected to the air inlet. connected. The valve core is roughly in the shape of a truncated cone, and two groups of air outlet holes at different heights are arranged on the peripheral surface, corresponding to the air inlet hole 111 and the air inlet ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com