Backflow preventer of hand-operated oil pump

The technology of a backflow prevention device and a hand-operated oil pump is applied to the components of the pumping device for elastic fluid, the pump, the piston pump, etc. Easy-to-manufacture, simple-to-construct effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

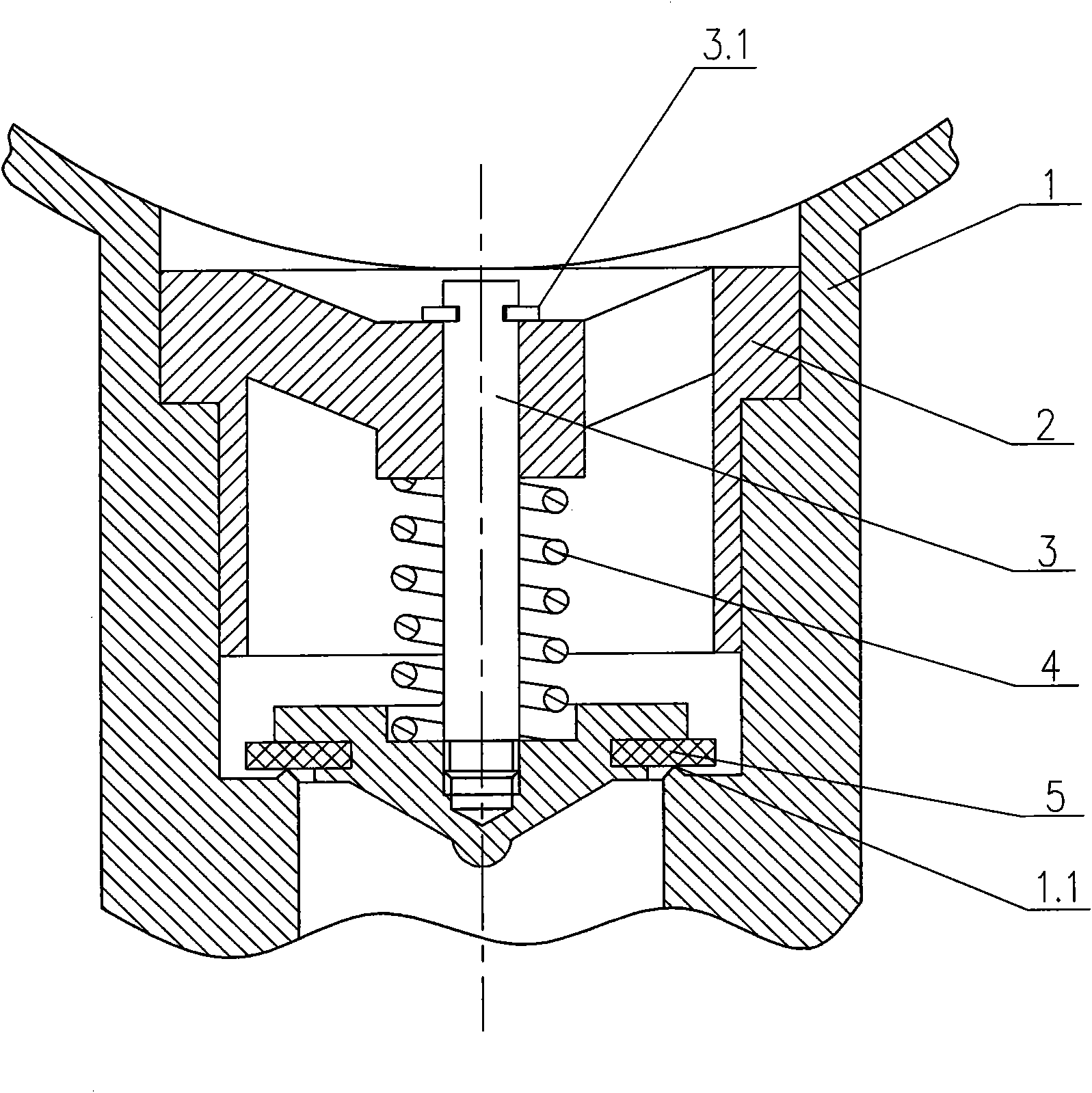

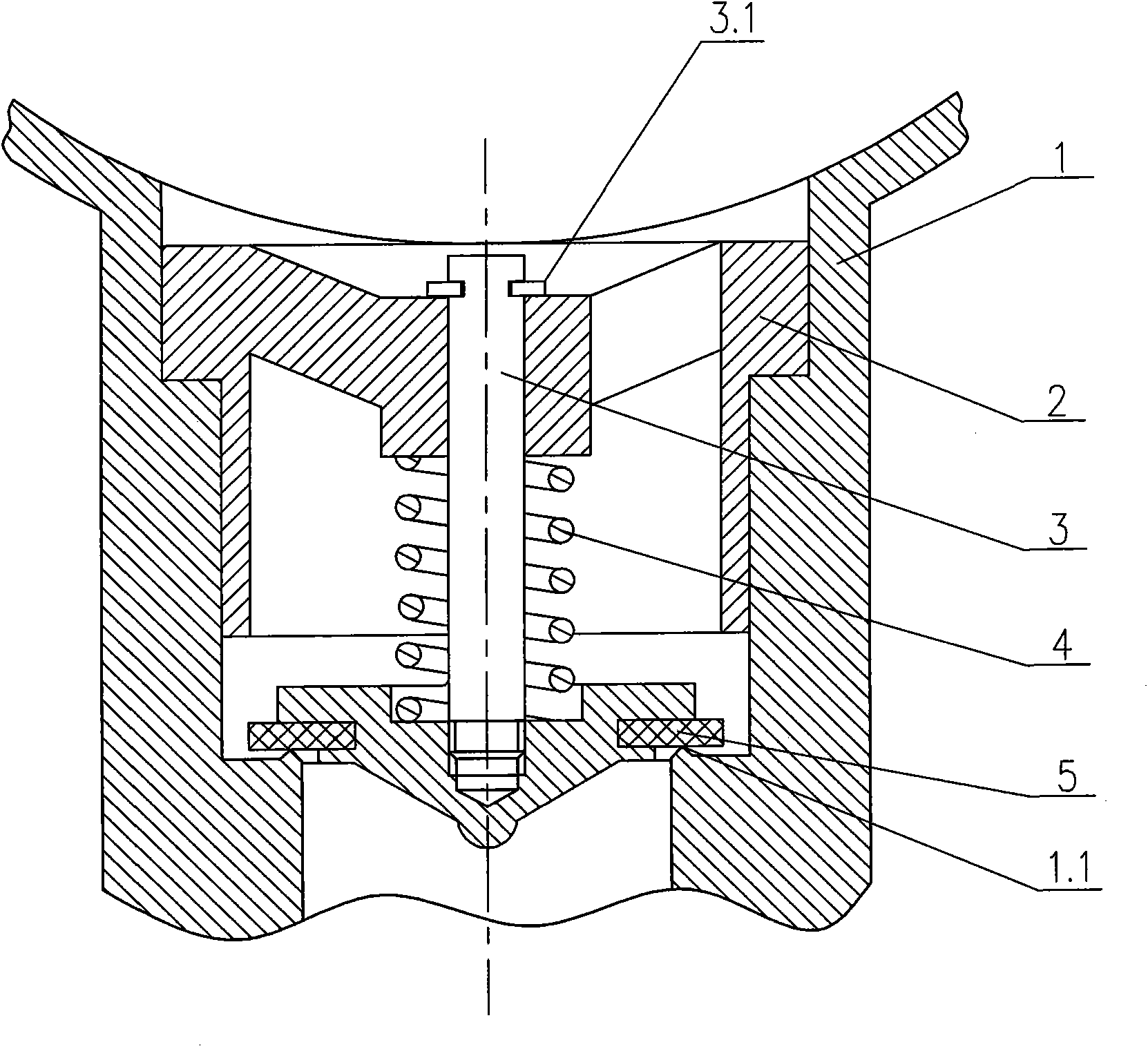

[0011] The present invention will be further described below according to accompanying drawing.

[0012] The anti-backflow device of the hand oil pump shown in the accompanying drawing is located at the oil inlet 1 of the pump and includes a built-in valve seat 2, valve core 3 and spring 4. The pump oil inlet 1 is located at the bottom of the pump body, and its inner hole is stepped. The inlet pipe with the smallest diameter is located at the bottom. The inner end surface of the inlet pipe is provided with an annular step 1.1, and the axial section of the step is an isosceles triangle. The valve seat 2 is cylindrical, and radial ribs are evenly distributed in the inner opening of the big end, and the intersection nodes of the ribs are provided with axial through holes. It passes through the axial through hole with loose fit, and is axially limited by the circlip 3.1, and the rubber flat pad 5 is embedded in the outer frame of the umbrella top facing downward. The above-mentio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com