Method for grouting and sealing plate-type ballastless track

A technology of slab-type ballastless track and ballastless track, which is applied in the directions of track, track laying, track maintenance, etc., can solve the problems of time-consuming and labor-intensive edge banding, pollution, poor appearance effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

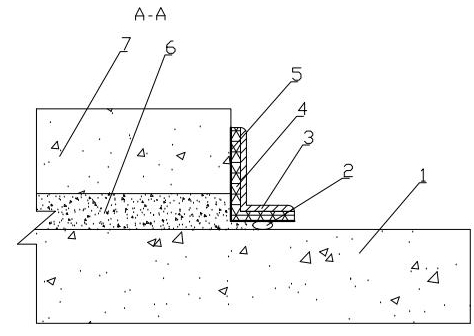

[0013] Such as figure 1 and figure 2 The shown embodiment: a method for grouting edge sealing of a plate-type ballastless track, including the following steps: 1) cleaning the top surface of the base plate 1; 2) laying rubber hoses: on the top surface of the part of the base plate 1 whose width exceeds the track plate 7 Lay the rubber hose 2 along the length direction of the track plate 7. The rubber hose must not invade the gap between the track plate and the base plate. The rubber hose is disconnected at the fine adjustment claw of the track plate. 3) laying industrial felt and air-permeable cloth: first wrap the industrial felt 4 on the outer surface of the unequal angle steel 3, and then attach the air-permeable cloth 5 to the surface of the industrial felt 4, or first place the industrial felt and air-permeable cloth The air-permeable cloth is laminated along the length direction of the two and then sewed. Generally, a layer of industrial felt and a layer of air-permeab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com