Special lubricating oil for compound nitrogen/hydrogen gas compressor

A nitrogen-hydrogen and compressor technology, applied in the field of lubricating oil, can solve the problems of accelerated oxidation, deterioration into gel and coking, increase of friction coefficient between fluid layers, and increase of compressor workload, etc., to improve sanitary conditions and noise isolation. , The effect of reducing equipment wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The special lubricating oil for the composite nitrogen-hydrogen compressor of the present invention is formulated according to the mass percentage of the following raw materials: 80% of mineral base oil BS120, 12% of modified castor oil, 3% of polyisobutylene, 3% of dibutyl ester, 1.95% of silicone oil, Nitrogen 0.05%.

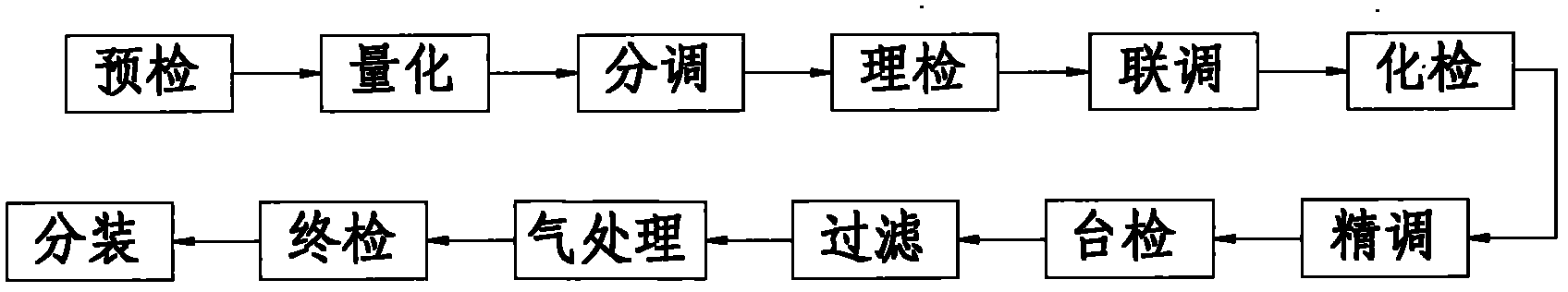

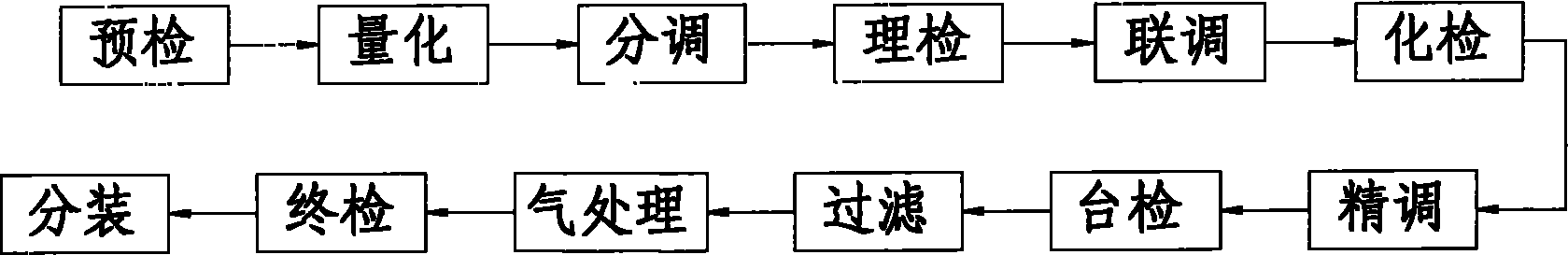

[0027] Its preparation process is as figure 1 As shown, the above raw materials are prepared according to the process steps of: pre-inspection-quantification-sub-adjustment-physical inspection-joint adjustment-chemical inspection-fine adjustment-platform inspection-filtration-gas treatment-final inspection-subpackaging. Among them, pre-inspection: inspection of various physical and chemical indicators of raw materials; quantification: on the basis of pre-inspection, each raw material is weighed according to the aforementioned ratio; sub-adjustment: each component and part of the base oil are blended into a mother liquor, and the temperature is 80 ° C. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com