Mechanical arm and transport device provided with same

A technology of a robotic arm and a handling device is applied in the field of a robotic arm and a handling device having the robotic arm, which can solve problems such as hardening and liquid crystal leakage, and achieve the effects of reducing costs, solving the problem of insufficient cleanliness, and solving the problem of easy damage to the substrate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

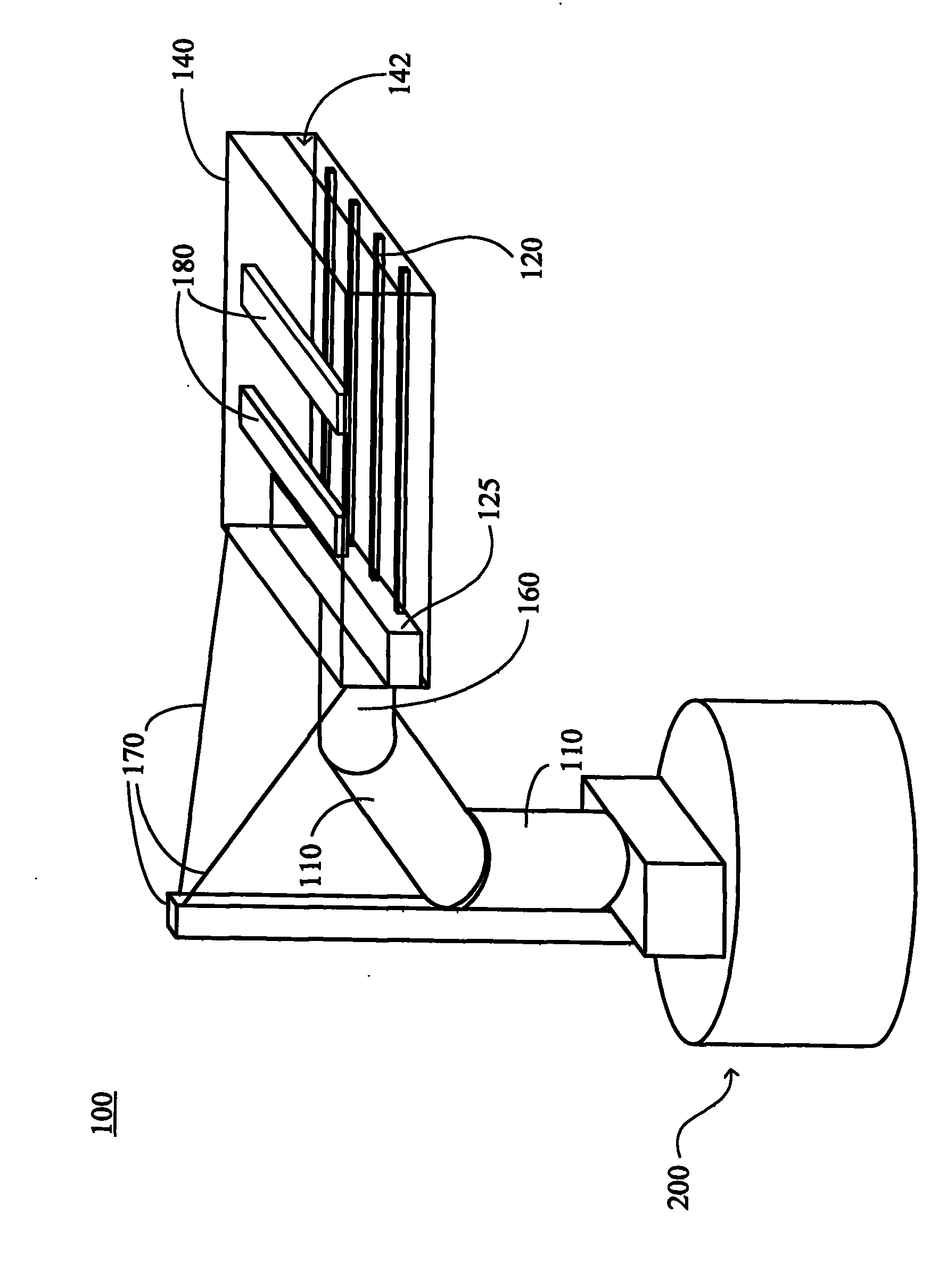

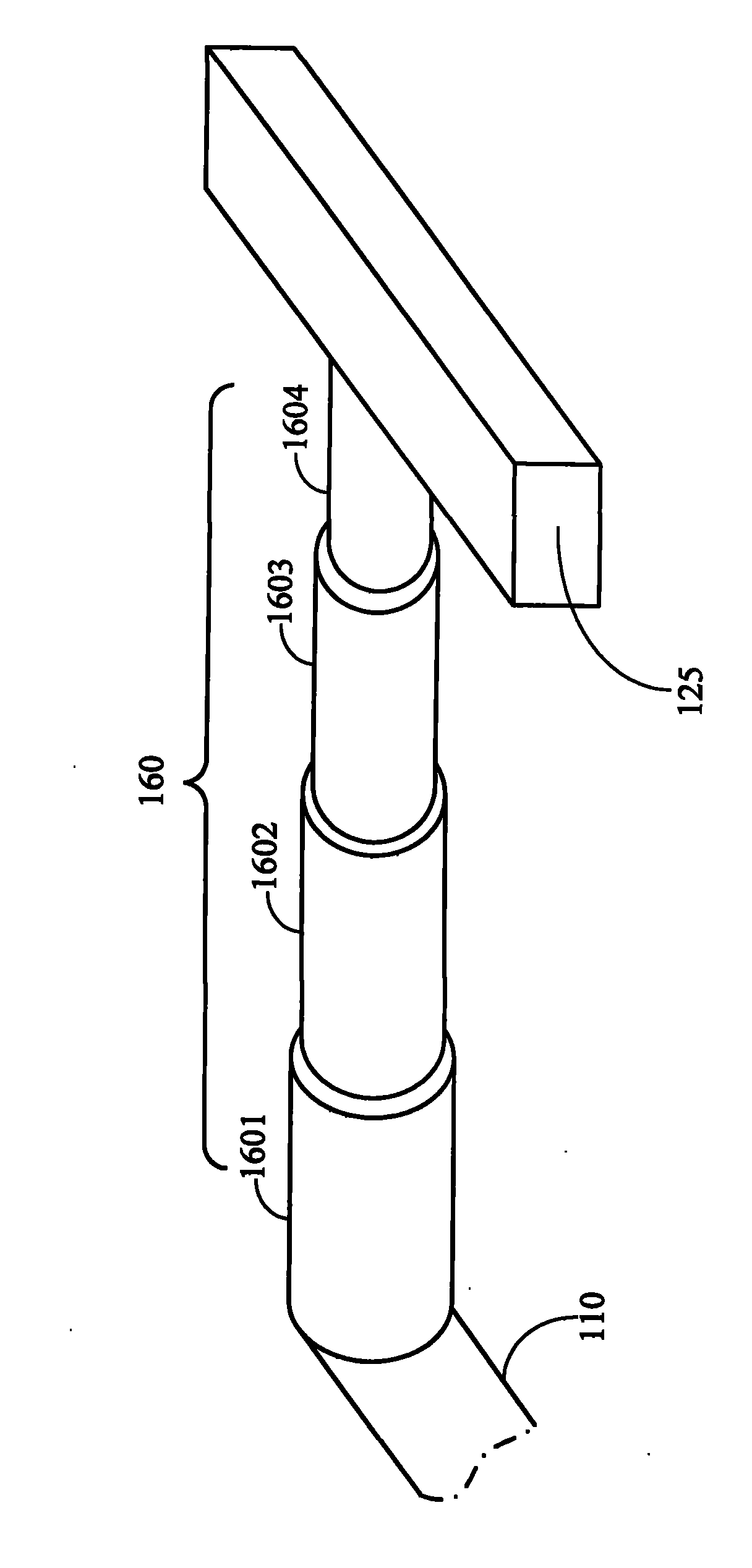

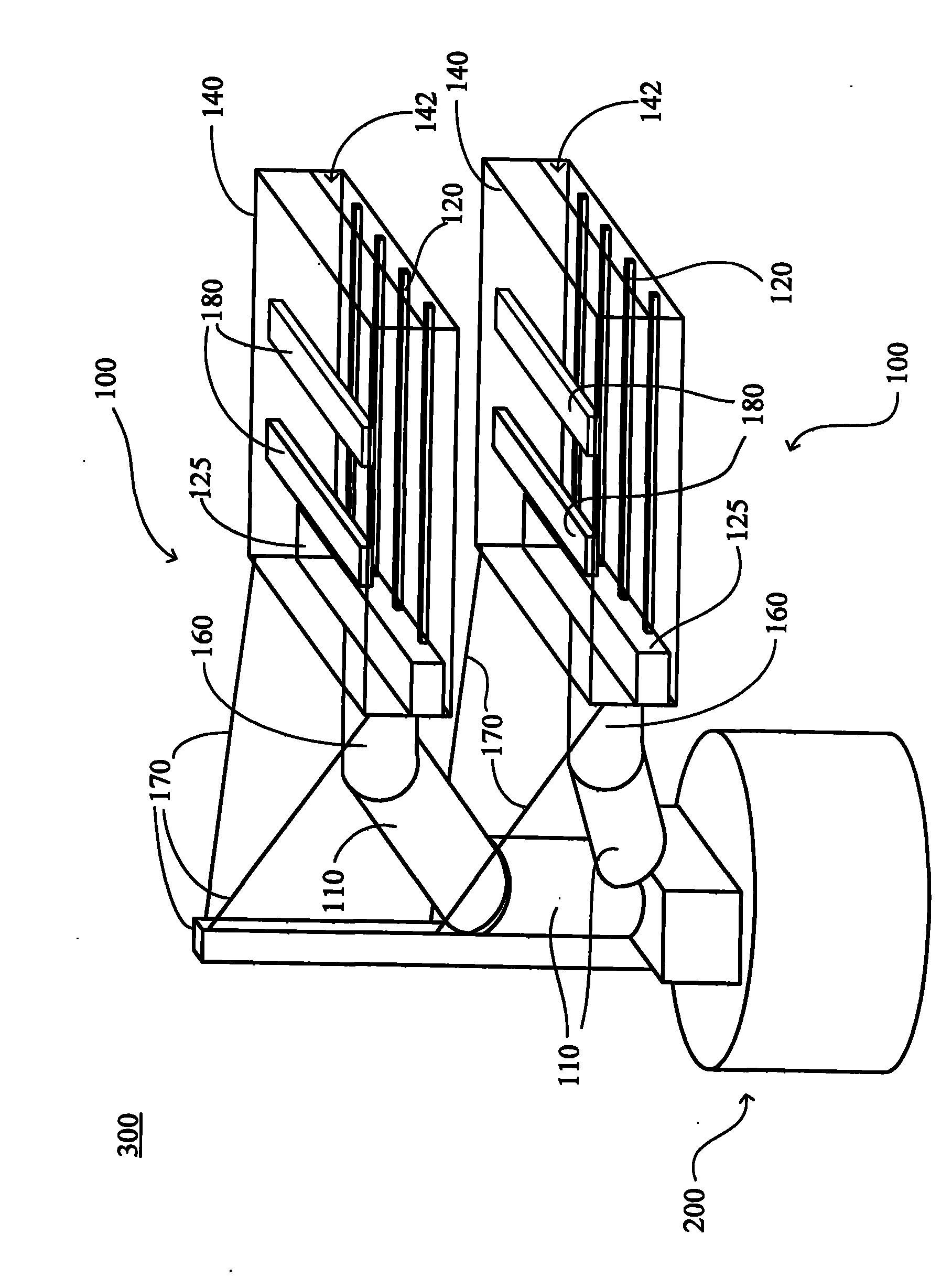

[0018] Please refer to figure 1 , figure 1 It is a three-dimensional schematic diagram of a robotic arm in a preferred embodiment of the present invention. The robotic arm 100 of this preferred embodiment is mounted on a base 200 . The robot arm 100 is used to transport a plate (not shown), wherein the glass substrate of the plate is either the above-mentioned TFT substrate and color filter substrate, or a laminated panel, especially a large size panel. The robot arm 100 includes several arms 110 , a bearing member 120 , a cavity 140 and a telescopic element 160 . The several arms 110 are combined through a plurality of joints (not shown), and the operation of the arms 110 can be controlled by a computer.

[0019] The carrying member 120 is used for carrying the plate. Preferably, the carrying member 120 is formed by arranging several cylinders and installed on a base 125 . In addition, the plurality of pillars can also be integrally formed with the base 125 .

[0020] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com