Top plate for metal can, method and apparatus for repairing same

A metal can and metal plate technology is applied in the field of metal can roofs and their repairing and repairing devices, and can solve the problems of inability to properly repair the damaged position of the laminated layer, inability to obtain sufficient film thickness, and unstable coating film thickness, etc. Achieve the effect of improving mass productivity, excellent uniformity, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below, refer to Figure 1 to Figure 14 Embodiments of the roof plate for metal cans of the present invention, its repair method, and repair device will be described.

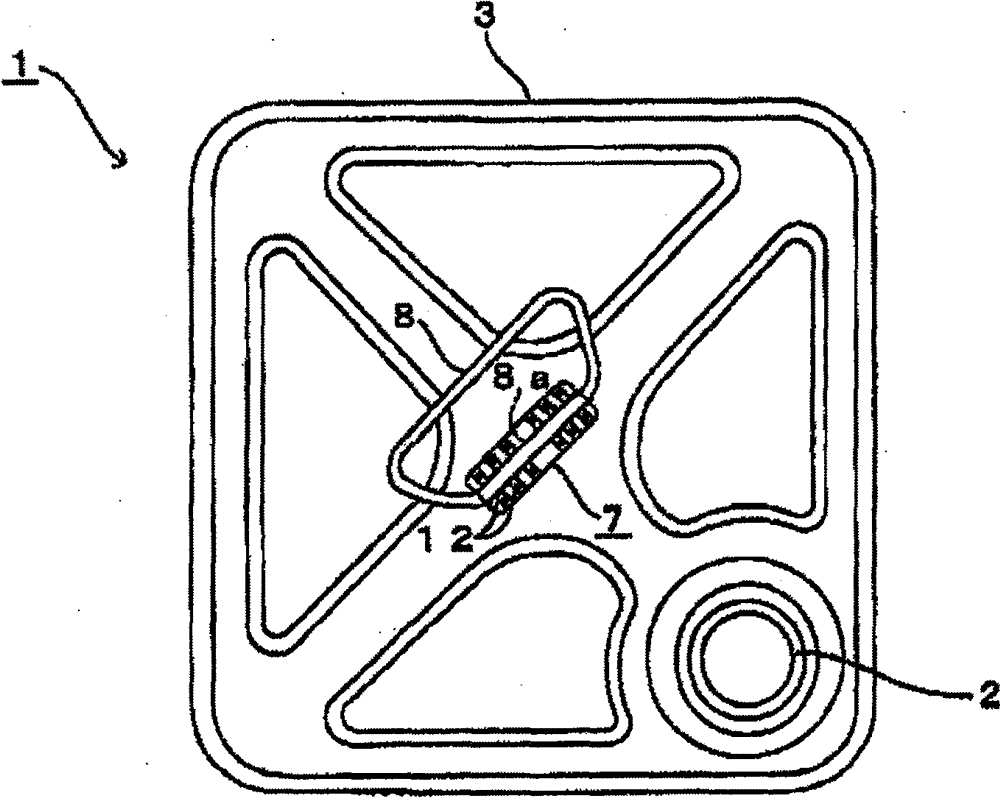

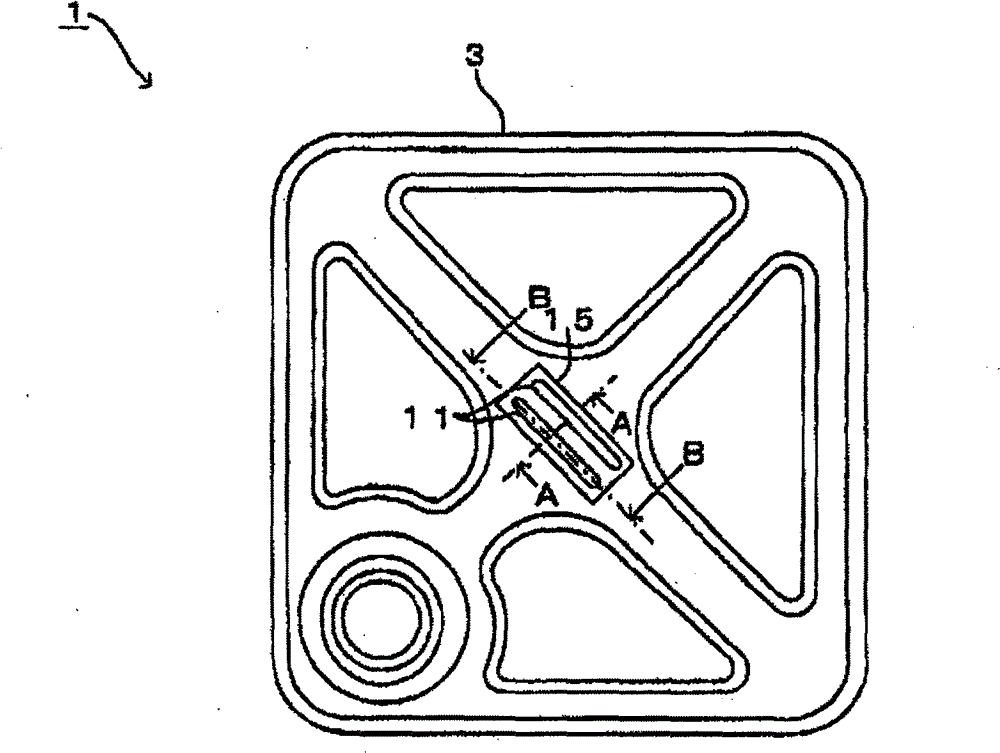

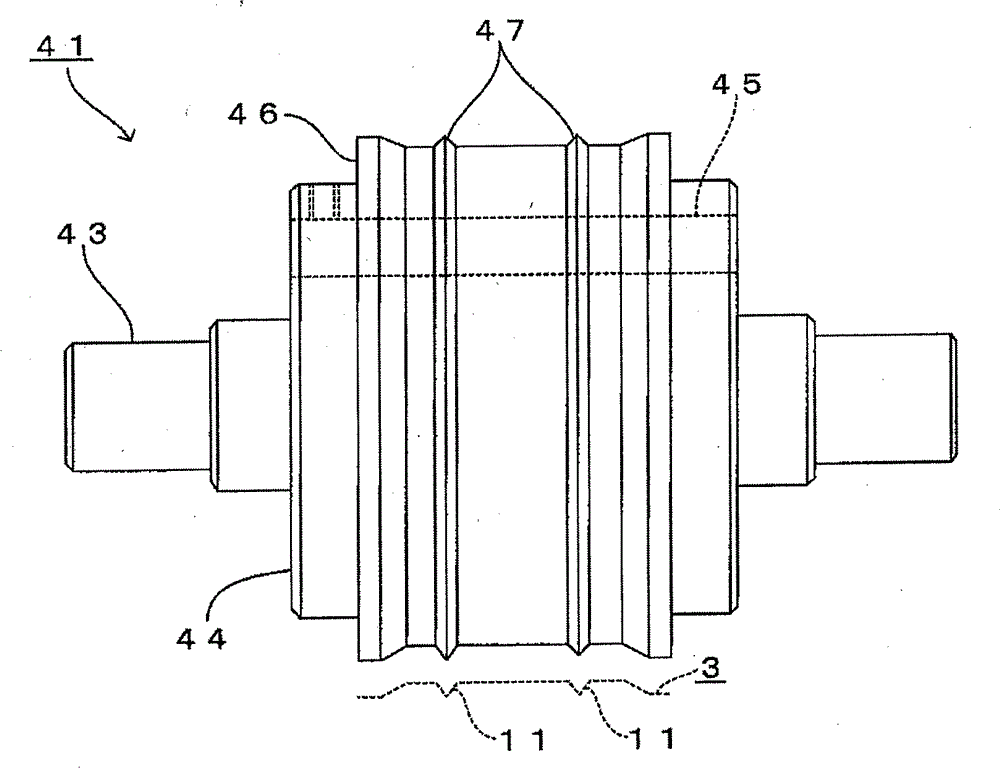

[0040] figure 1 It is a plan view showing the top plate 1 for metal cans of this embodiment, figure 2 Yes figure 1 bottom view. also, image 3 Yes figure 2 The A-A line sectional view, Figure 4 Yes figure 2 B-B line sectional view.

[0041] like figure 1 and figure 2 As shown, the top plate 1 for a metal can in this embodiment has a top plate main body 3 having a can mouth edge 2 which is substantially square in plan.

[0042] The roof main body 3 is made of laminated steel plates as laminated metal plates, such as image 3 and Figure 4 As shown, one side of its thickness direction ( image 3 and Figure 4 The surface above) (hereinafter referred to as the tank inner side) is composed of a laminated layer 5 of a resin material laminated on a steel plate 6 . This laminated layer 5 prev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com