Gentamycin sulfate capsule and preparation method thereof

A technology of gentamicin sulfate and capsules, which is applied in the fields of capsule transportation, pharmaceutical formulations, medical preparations of non-active ingredients, etc. It can solve the problems of difficult filling of capsules and unstable quality, and achieve fast dissolution rate and good stability , fast disintegration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

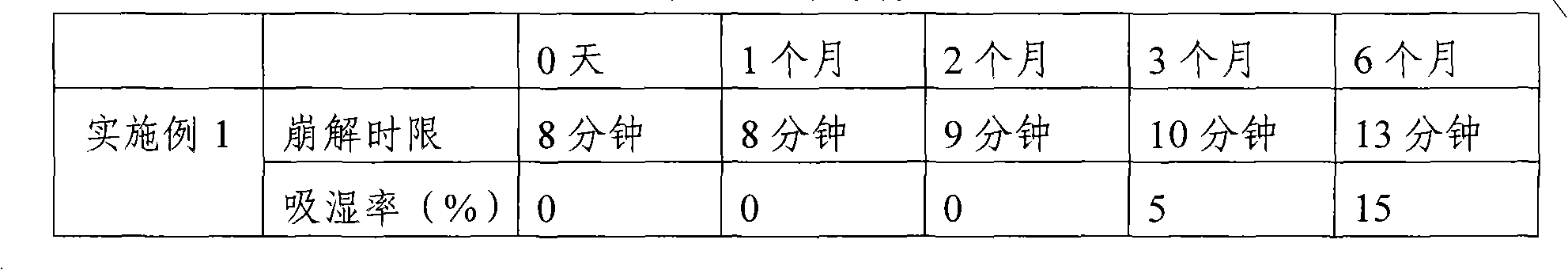

Embodiment 1

[0033] 1. Composition:

[0034] composition

Weight (g)

percentage(%)

750

30.61

700

28.57

microcrystalline methyl cellulose

200

8.16

Calcium sulfate

500

20.44

100

4.08

200

8.16

total

2450

100

[0035] 2. Preparation method:

[0036] 1) Weigh gentamicin sulfate, microcrystalline cellulose, starch, and calcium sulfate according to the prescription, then pulverize them respectively, dry them for 2 hours at a temperature of 55° C., and pass through a 100-mesh sieve;

[0037] 2) Mix gentamicin sulfate, microcrystalline methyl cellulose, starch, and calcium sulfate powder uniformly according to the method of equal addition, and the powder after mixing is white or off-white powder;

[0038] 3) Hypromellose is prepared into a concentration of 5% as an adhesive to make a soft material, ...

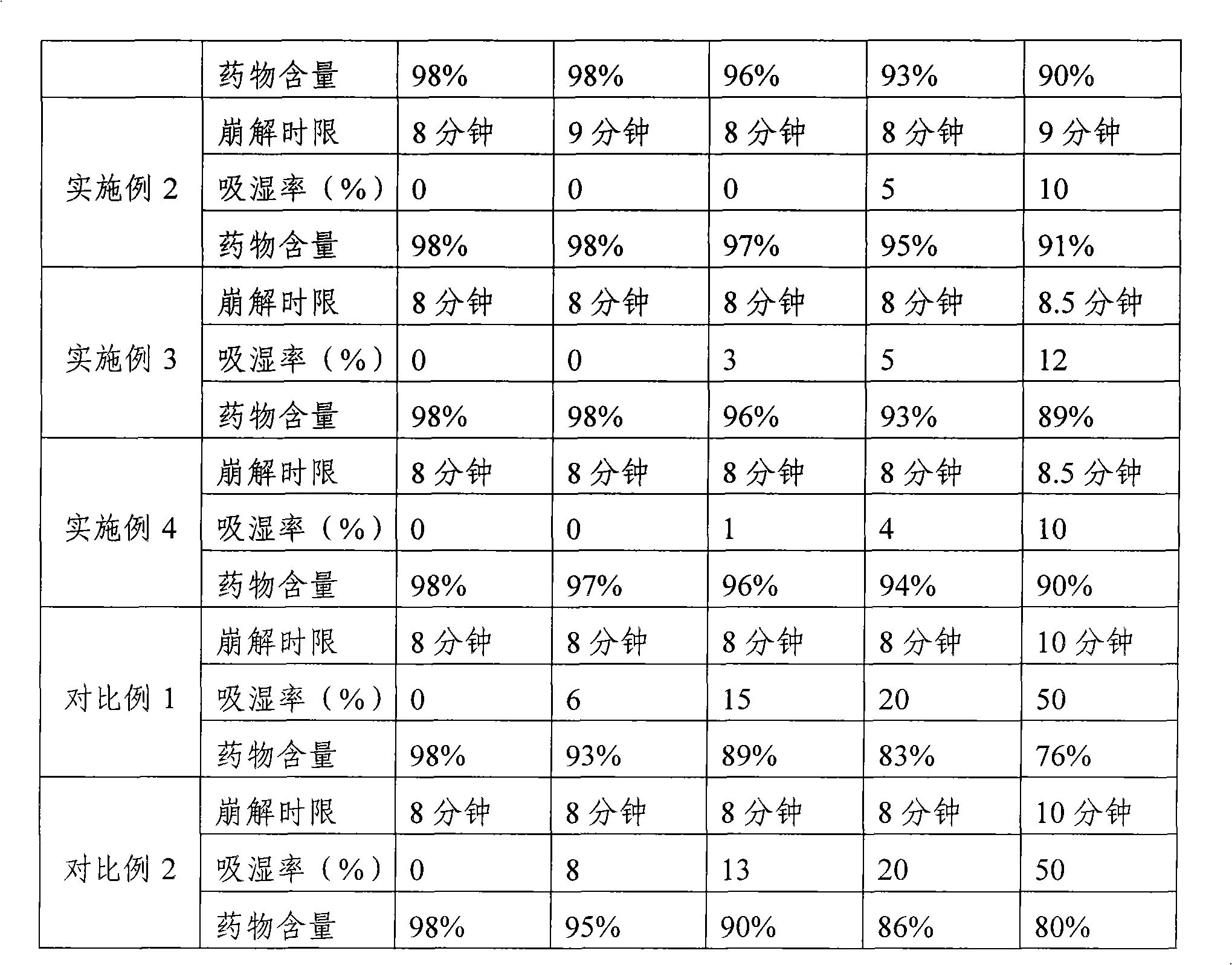

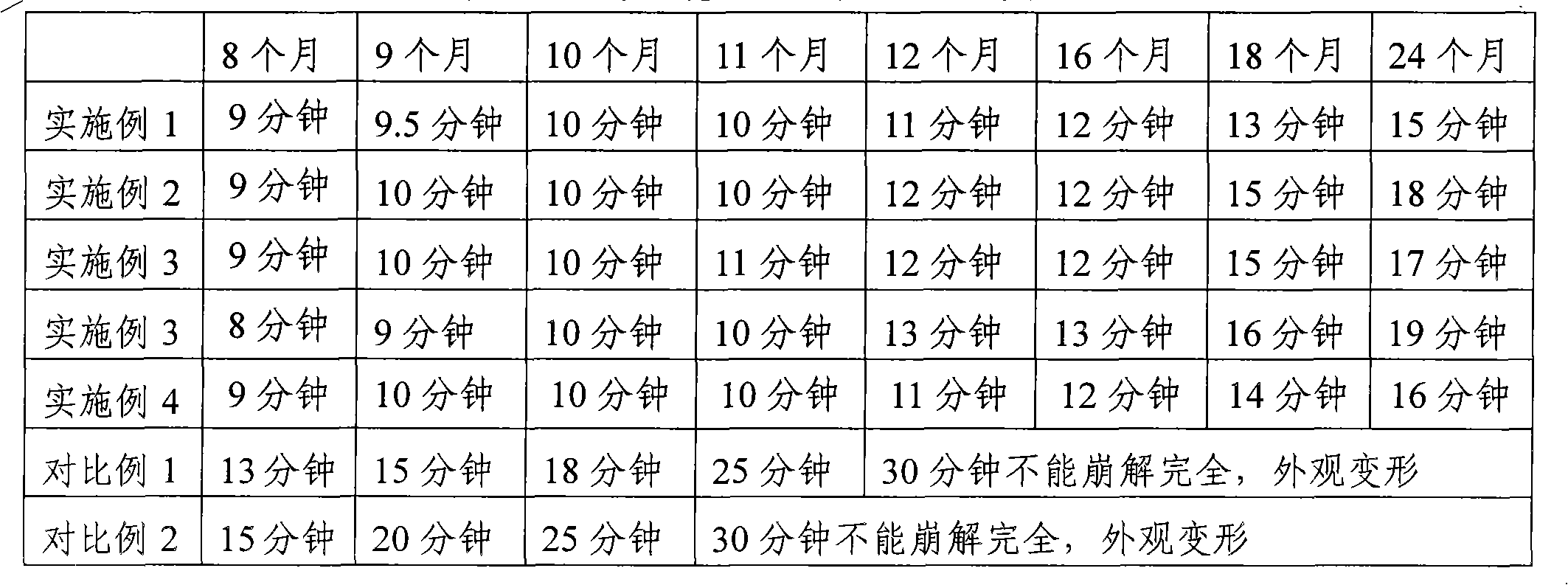

Embodiment 2

[0041] 1. Composition:

[0042] composition

Weight (g)

percentage(%)

750

27.27

1100

40

microcrystalline methyl cellulose

200

7.27

Calcium sulfate

400

14.55

100

3.64

[0043] silica

200

7.27

total

2750

100

[0044] 2. Preparation method:

[0045] 1) Weigh gentamicin sulfate, microcrystalline cellulose, pregelatinized starch, and calcium sulfate according to the composition, then pulverize them respectively, dry them for 2 hours at a temperature of 60° C., and pass through a 100-mesh sieve;

[0046] 2) Mix gentamicin sulfate, microcrystalline methyl cellulose, pregelatinized starch, and calcium sulfate powder evenly according to the method of equal addition, and the powder after mixing is white or off-white powder;

[0047] 3) Hypromellose is prepared into a concentration of...

Embodiment 3

[0050] 1. Composition:

[0051] composition

Weight (g)

percentage(%)

750

27.27

starch

1400

50.91

microcrystalline methyl cellulose

20

0.73

Calcium sulfate

200

7.27

Hypromellose

20

0.73

talcum powder

360

13.09

total

2750

100

[0052] 2. Preparation method:

[0053] 1) Weigh gentamicin sulfate, microcrystalline cellulose, starch, and calcium sulfate according to the composition, then pulverize them respectively, dry them at 60°C for 2 hours, and pass through a 100-mesh sieve;

[0054] 2) Mix the mixed powder of gentamicin sulfate and microcrystalline methyl cellulose with the mixed powder of starch and calcium sulfate according to the method of equal increase, and the mixed powder is white or off-white powder;

[0055] 3) Hypromellose is prepared into a concentration of 5% as an adhesive to make a soft material, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com