Detection method used for failure analysis of semiconductor device

A detection method and failure analysis technology, applied in semiconductor/solid-state device testing/measurement, preparation of test samples, etc., can solve problems such as poor observation effect, fast corrosion rate, and inability to truly reflect the depth of source/drain regions, etc. The effect of high integrity, small corrosion damage, easy observation and detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

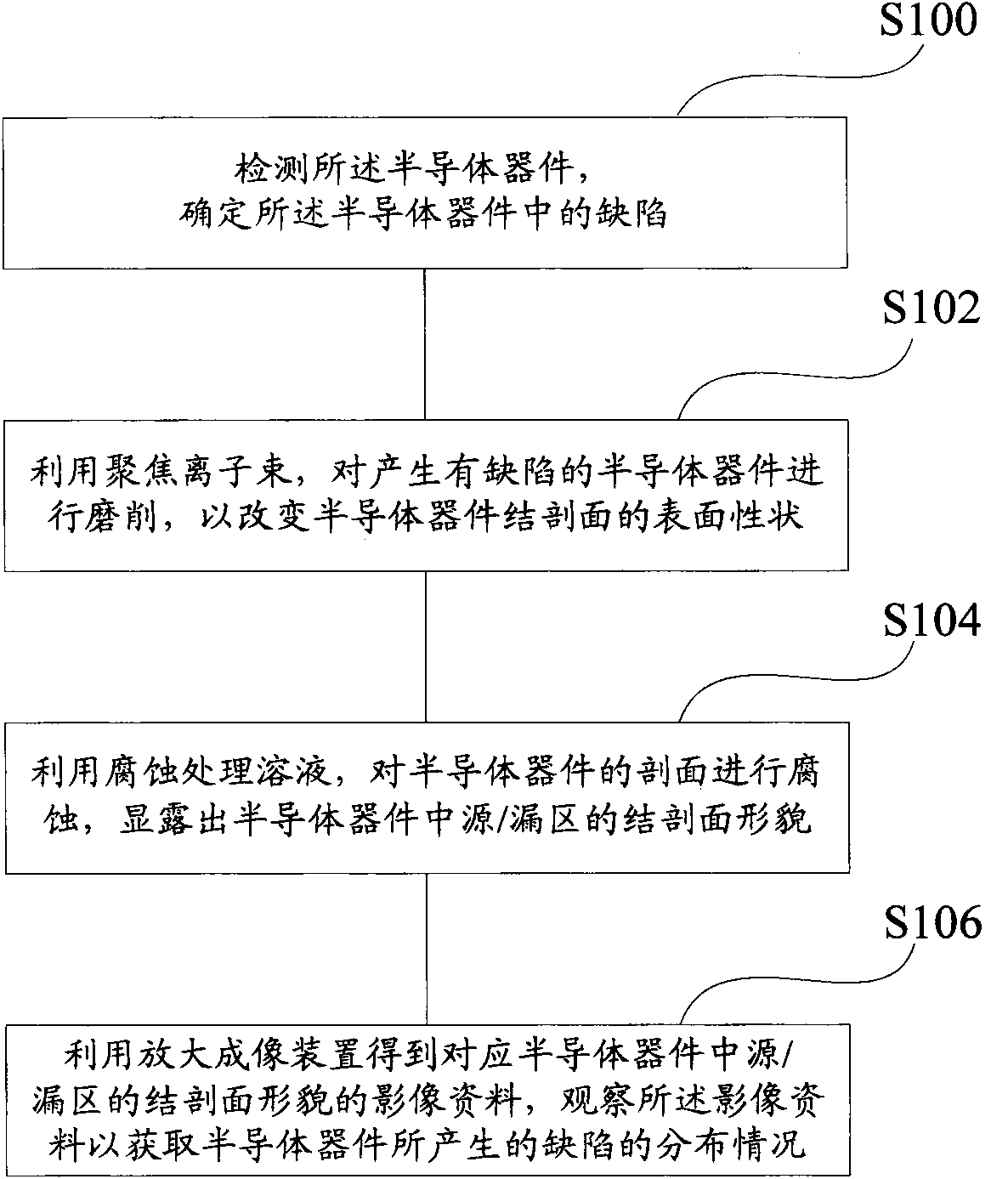

[0029] As can be seen from the background technology, the inventors of the present invention have found that in the failure analysis of semiconductor devices, when the semiconductor device to be analyzed is directly corroded by a highly corrosive corrosion treatment solution, it is easy to cause over-corrosion to the semiconductor device and damage the semiconductor device. Moreover, this traditional chemical coloring treatment method cannot effectively highlight the junction and well levels of the semiconductor device, and cannot provide a basis for judging the failure of the source / drain junction of the device.

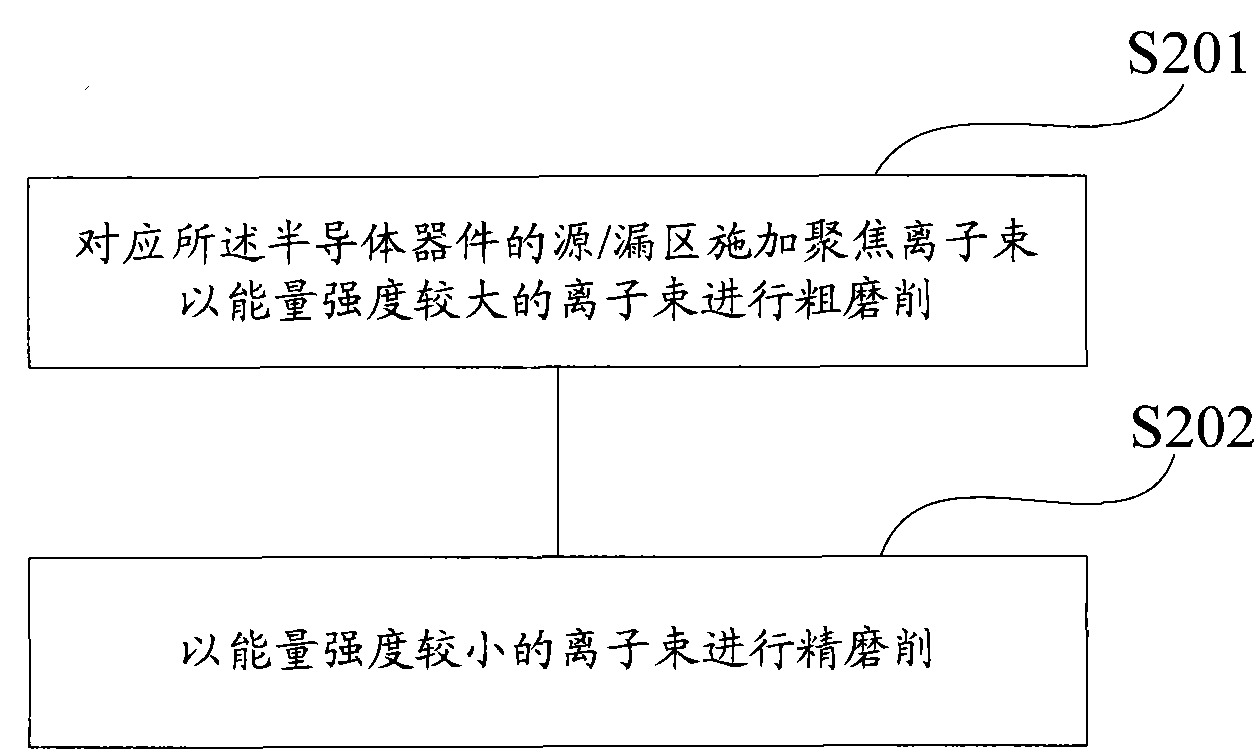

[0030] Therefore, in the manufacturing process of semiconductor devices, the inventors of the present invention conceived of adopting the focused ion beam grinding technology first, first changing the surface properties of the junction section, making it in an overstressed state, and then using the etching treatment solution for subsequent etching, so as to be able to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com