Bend-resistance multimode optical fiber

A multi-mode optical fiber and anti-bending technology, which is applied in the field of optical communication, can solve the problems of poor anti-bending performance of optical fiber, negative impact of multi-mode bandwidth, and further improvement of optical fiber, and achieve simple and effective manufacturing method and low macrobending additional attenuation , the effect of increasing the bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

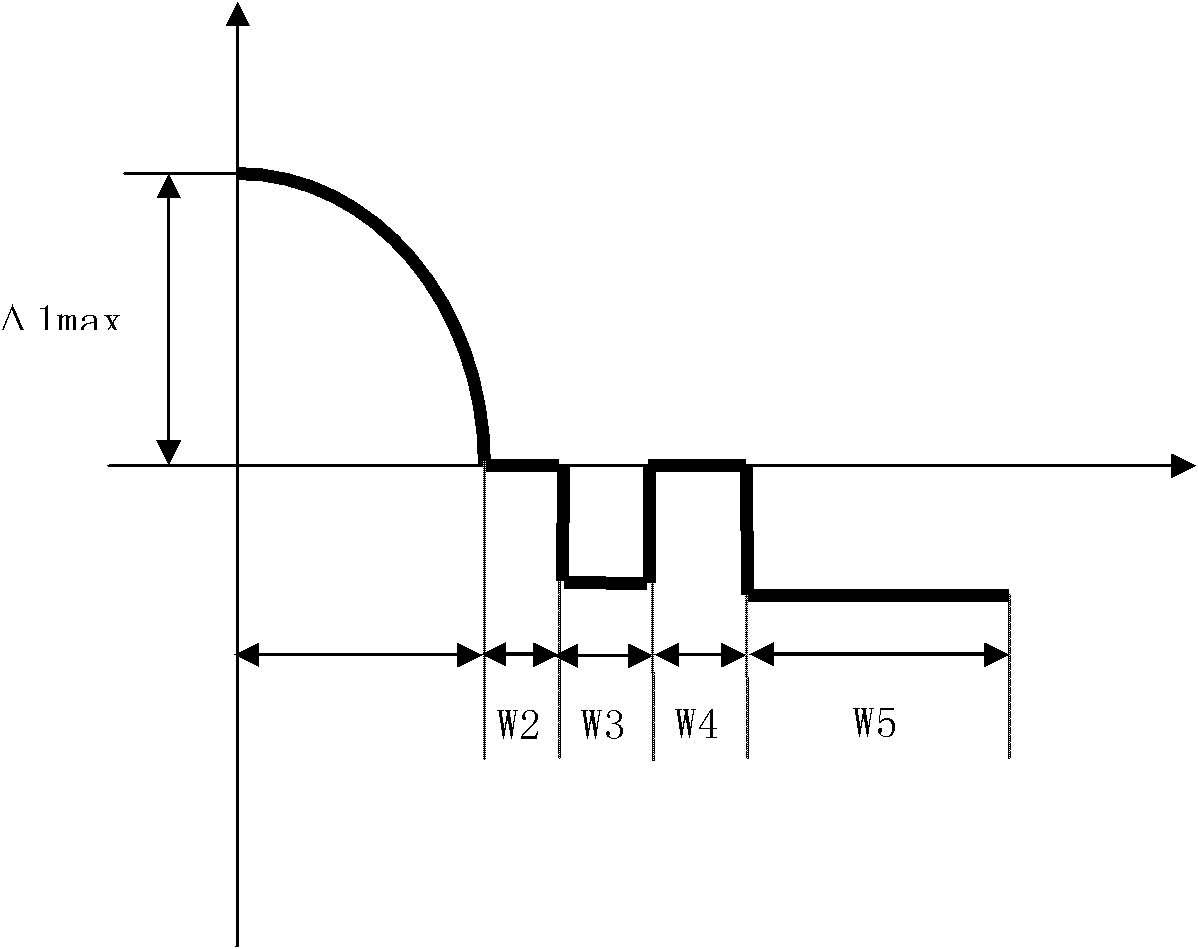

[0048] According to the design of the technical plan (as attached figure 1 Shown), and the manufacturing method of the present invention, prepared a group of prefabricated rods and drawing, adopt the double-layer coating of multimode optical fiber and the drawing speed of 600 m / min, the structure and main performance parameters of optical fiber are shown in Table 1.

[0049] Table 1

[0050]

[0051]

Embodiment 2

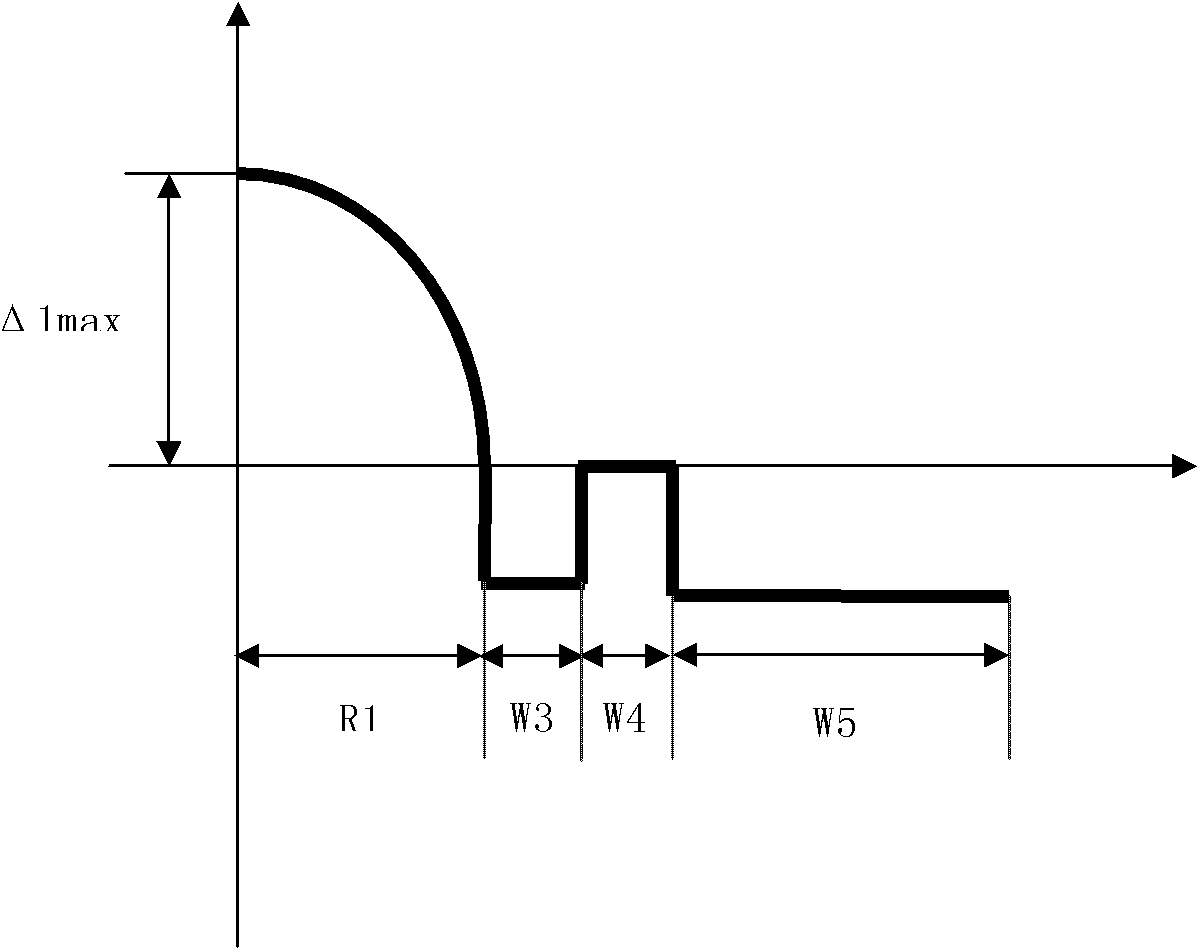

[0053] According to the design of the technical plan (as attached figure 2 Shown), and the manufacturing method of the present invention, prepared a group of prefabricated rods and drawing, adopting the double-layer coating of multimode optical fiber and the drawing speed of 600 m / min, the structure and main performance parameters of the optical fiber are shown in Table 2.

[0054] Table 2

[0055]

[0056]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com