Non-leakage idling resistant centrifugal pump

A centrifugal pump, non-leakage technology, applied in the direction of pumps, pump components, non-variable pumps, etc., can solve the problems of difficult use, poor sealing performance, inconvenient operation, etc., to achieve simple design and operation, stable and reliable performance, sealing better effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

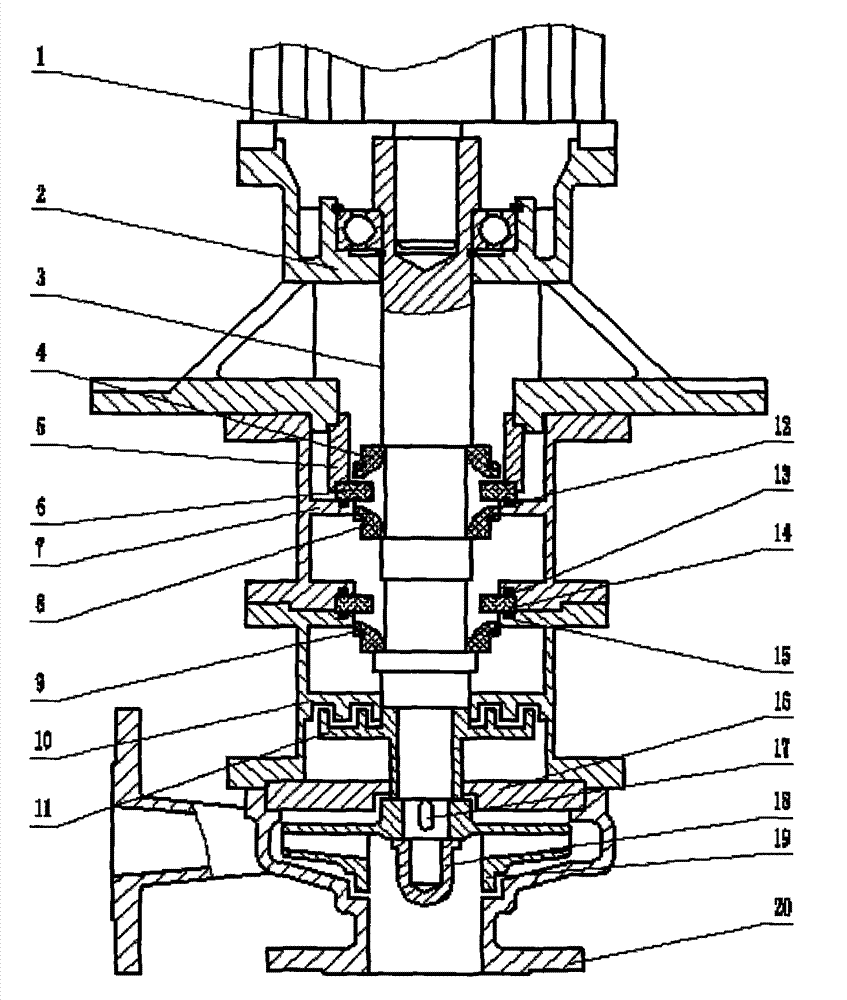

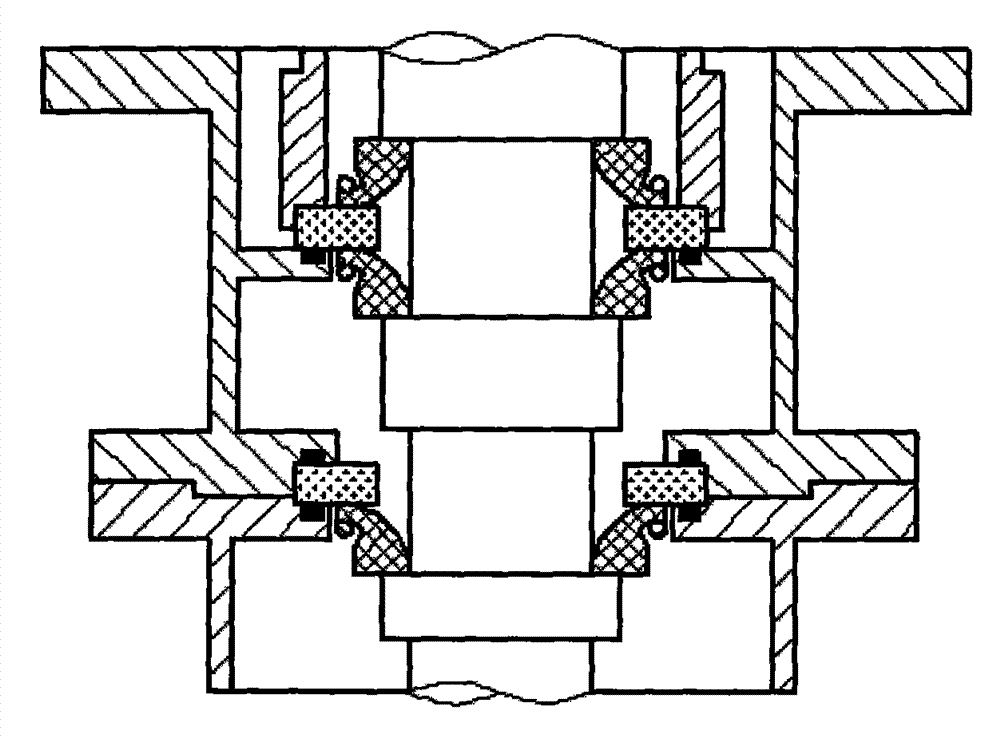

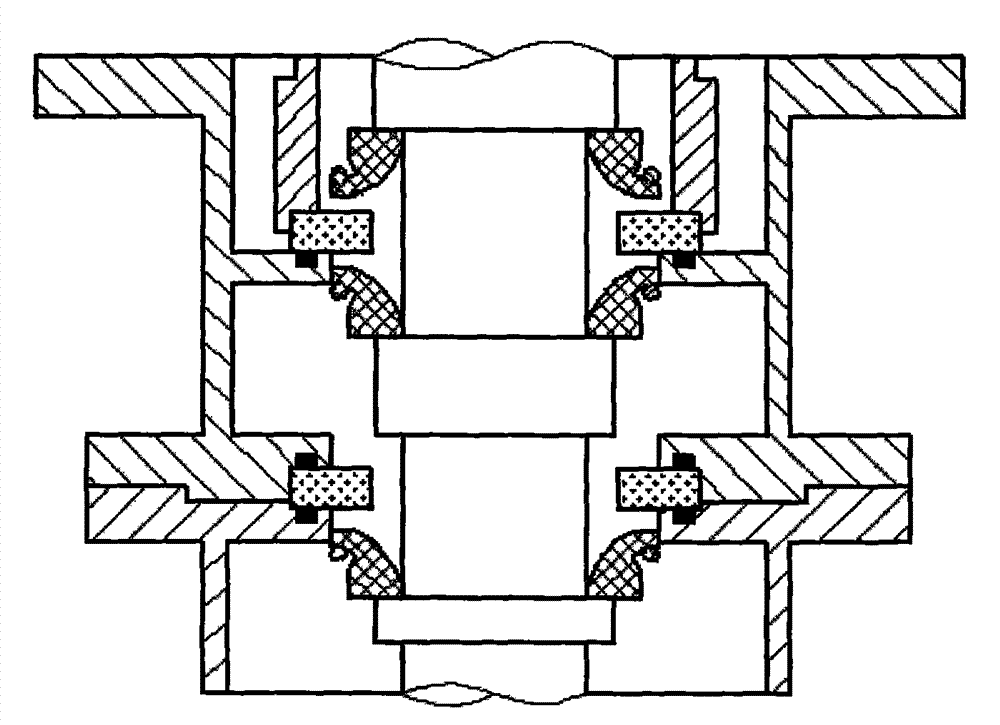

[0028] The following examples further illustrate the leakage-free idling-resistant centrifugal pump of the present invention: (1) motor and (2) bracket, (7) middle barrel (1) screw bolt; (2) bracket compression (5) static ring Seat, (6) static ring I, (12) O-ring (1) embedded in the grooved (7) middle cylinder (1); (4) power centrifugal shaft seal①, (8) power centrifugal shaft seal② , (9) Power centrifugal shaft seal ③ is tightly matched with (3) pump shaft; (7) middle cylinder (1) is connected with (10) middle cylinder (2), and (14) static ring II is embedded by (13) O Rings (2), (15) O-rings (3) are embedded in grooved (7) middle cylinder (1), (10) middle cylinder (2); (11) labyrinth or auxiliary impeller dynamic seal clearance fit Control; the lower part is equipped with (16) back cover, (17) key, (18) lock nut, (19) impeller, (20) pump body. When the pump rotates, all the parts tightly matched with the pump shaft also move. The liquid in the pump body is sealed by the laby...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com