Lithologic density long-spacing data acquisition and processing thick film circuit

A data acquisition and processing, thick film circuit technology, used in earth-moving drilling, wellbore/well components, etc., can solve the problems of affecting sampling accuracy, difficult to maintain, easy to damage components, etc., to achieve low circuit temperature drift and easy maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

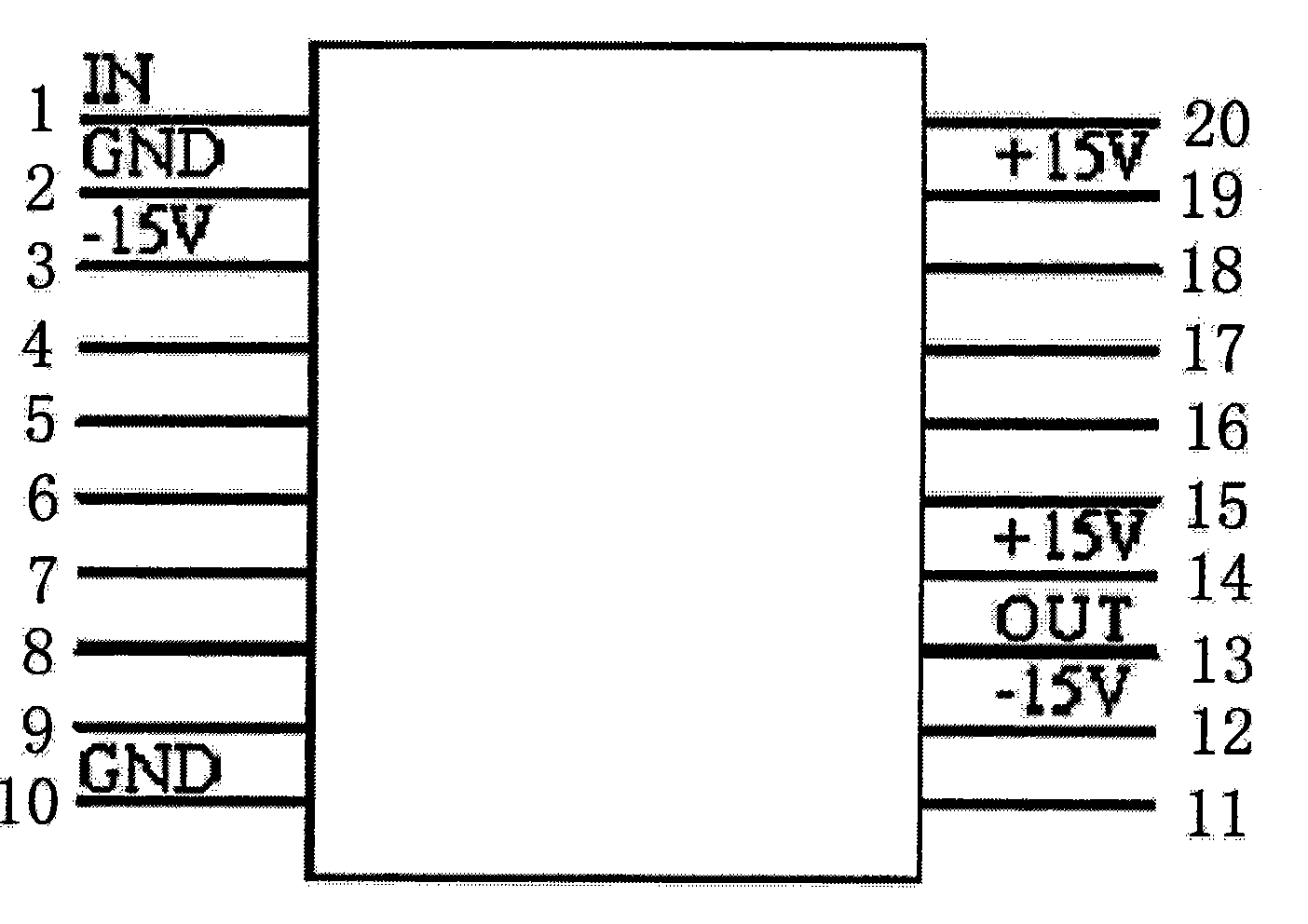

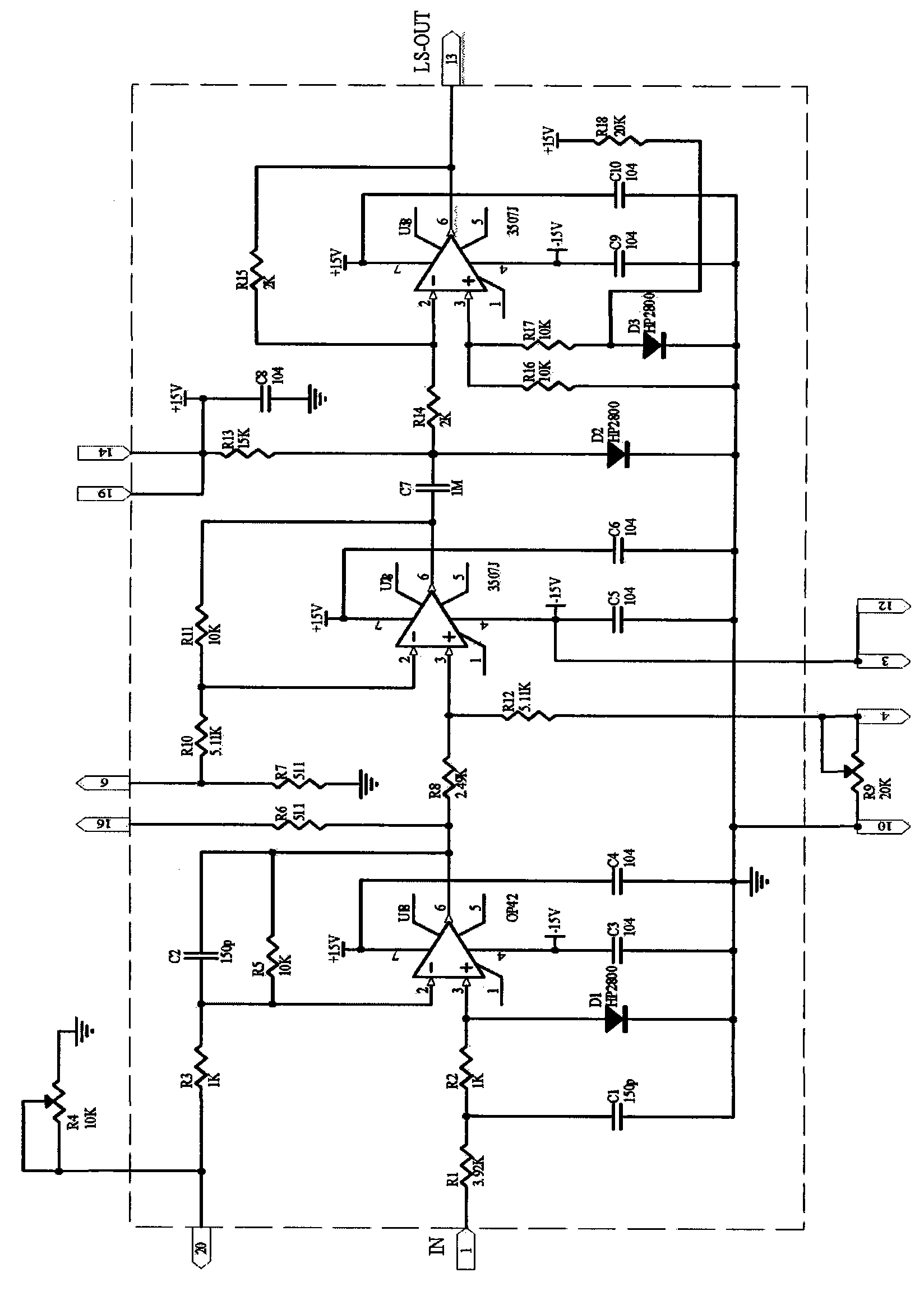

[0014] see figure 1 , figure 2 , a kind of lithological density long source distance data acquisition thick film circuit, comprises rectangular thick film circuit block, comprises a rectangular thick film circuit block, and this thick film circuit block comprises 20 pin pins, is divided into two rows, each row 10 pins, of which pins 1 to 10 of the thick film are arranged on the left side of the thick film circuit block from top to bottom, and pins 11 to 20 of the thick film are arranged on the right side of the thick film circuit block from bottom to top, of which Pin 1 is the long source distance signal IN input terminal, pin 10 of the thick film is the ground, pin 16 of the thick film and pin 6 of the thick film are connected to the delay circuit, pin 16 is the input signal of the delay circuit, and pin 6 of the thick film is input delay For the signal processed by the circuit, pin 13 of the thick film is the short source distance signal output terminal, pin 3 and pin 12 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com