Grouting soil nail for triangularly arranging reinforcing steel bars

A triangular and steel bar technology, which is applied in the field of grouting soil nails, can solve the problems that soil nails do not have bending resistance, and achieve the effects of good safety and stability, high bending resistance, and good bending strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

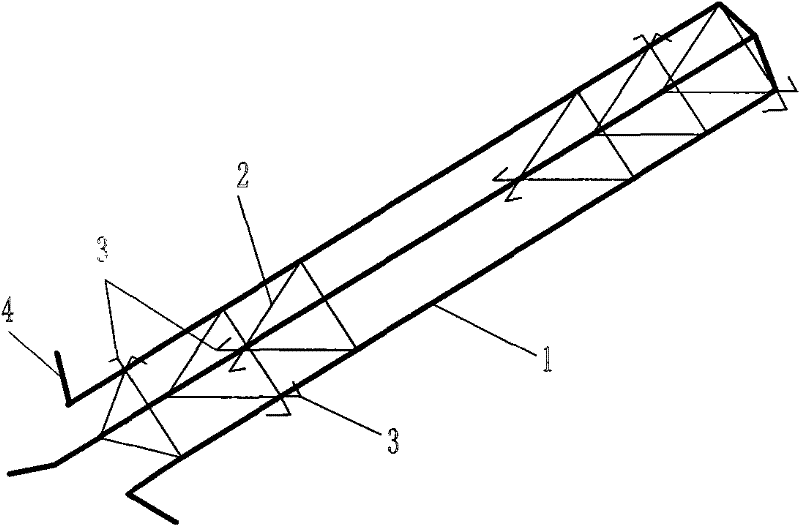

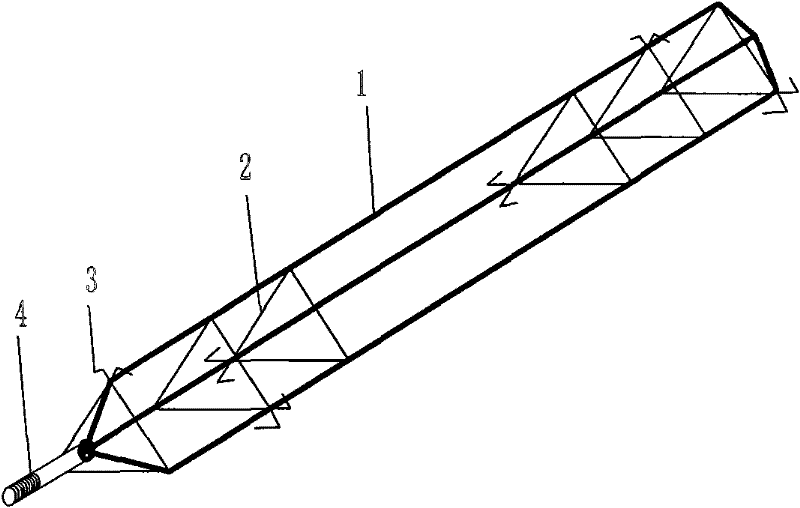

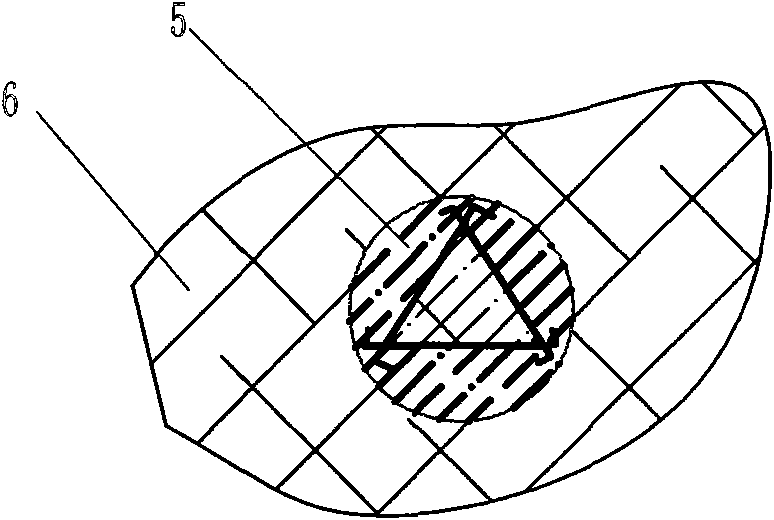

[0018] Such as figure 1 As shown, one of the schematic diagrams of the structure of the soil nailing reinforcement of the present invention is a grouting soil nail for the triangular arrangement of reinforcement bars that constitute the connection device 4 after one end of the main reinforcement bar is caged. The soil nail is composed of a steel bar and a cement slurry 5 wrapped around the steel bar; the steel bar has a main bar 1 and an auxiliary bar 2, and the main bar is distributed in a triangle on the cross section of the soil nail, and the auxiliary bar is surrounded by a triangular set and fixed on the main bar and a plurality of auxiliary reinforcements are arranged along the length direction of the soil nail, and the two heads of the auxiliary reinforcements surrounded by a triangle protrude and bend into support heads 3 . The connecting device at one end of the steel bar is formed by the main bar protruding from the head. The triangular arrangement of the reinforcin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com