Method for preparing dicyclopentadiene and emulsifying packed tower used thereby

A technology of dicyclopentadiene and packed towers, which is applied in the purification/separation of hydrocarbons, chemical instruments and methods, organic chemistry, etc., can solve the problems of high energy consumption and low yield of dicyclopentadiene, and achieve high separation efficiency , Simple structure and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

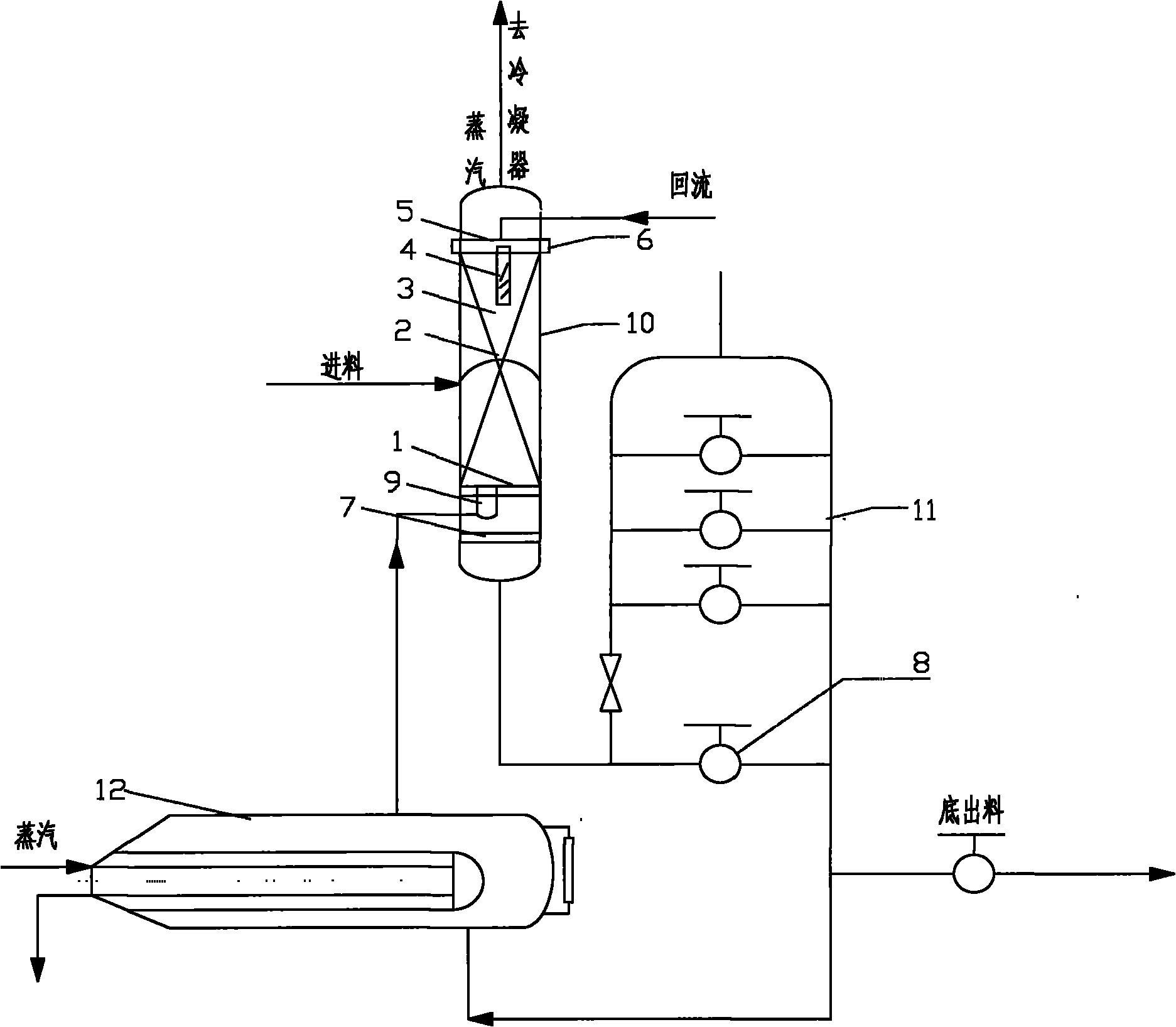

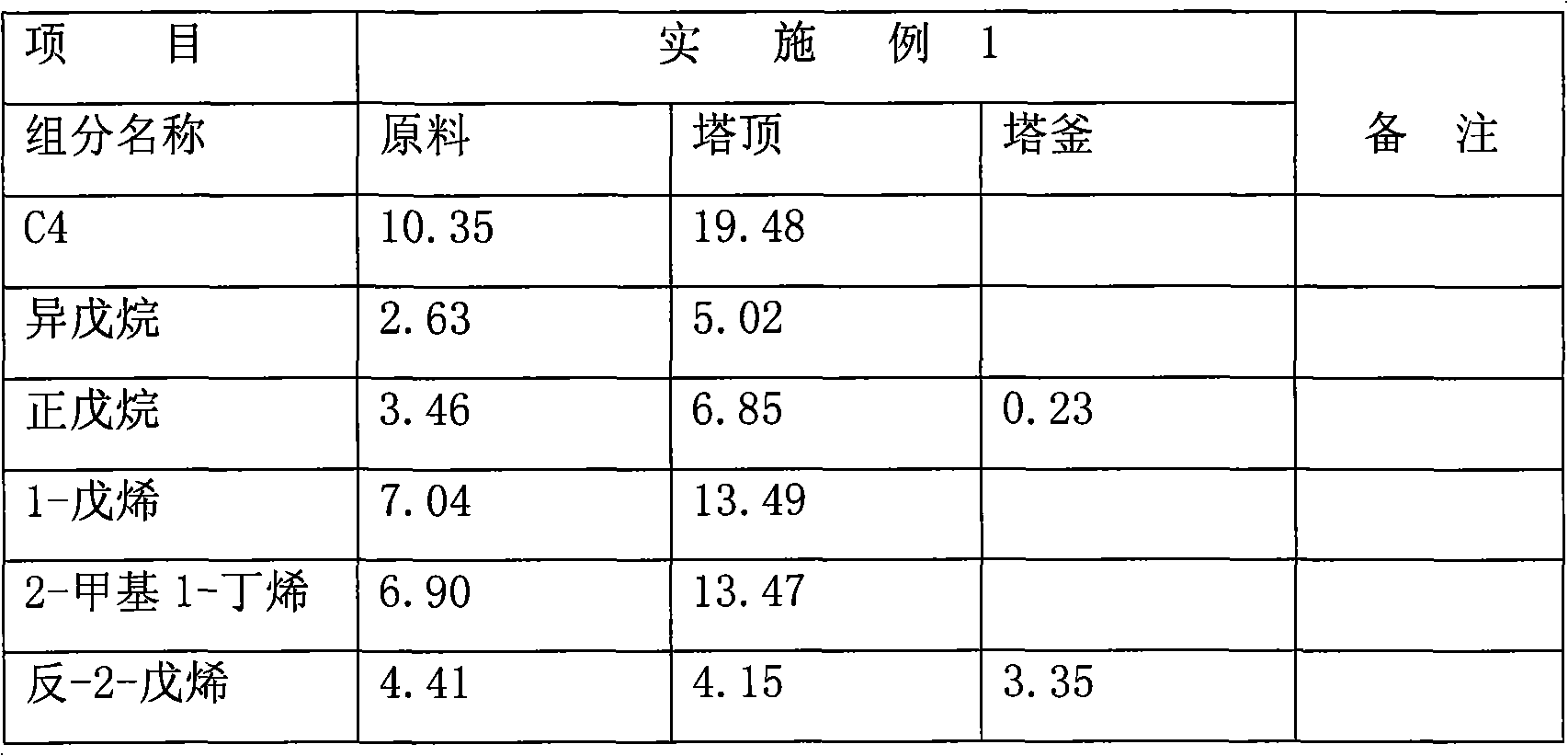

[0042] An emulsified packed tower with a diameter of 50mm and a metal Θ ring of Φ6*6*0.2 inside. The volume of the tower kettle is 1000ml and the height is 2.8 meters (equivalent to 40 theoretical plates). The middle part enters the reactive distillation tower, the feed temperature is controlled at 30°C, the tower top temperature is controlled at 56°C, the tower bottom temperature is increased to 90°C, the reflux ratio is controlled at 8, the tower top operating pressure is controlled at 0.20Mpa, and the cracking C5 The isoprene in the distillate is separated from the top of the tower together with other low-boiling point hydrocarbons through rectification, and the isoprene is separated in the extraction tower; and the cyclopentadiene in the feed is dimerized into dicyclopentadiene Together with piperylene and other high-boiling hydrocarbons, it is discharged from the bottom of the tower and sent to the piperylene tower and the dicyclopentadiene tower to obtain the product. Th...

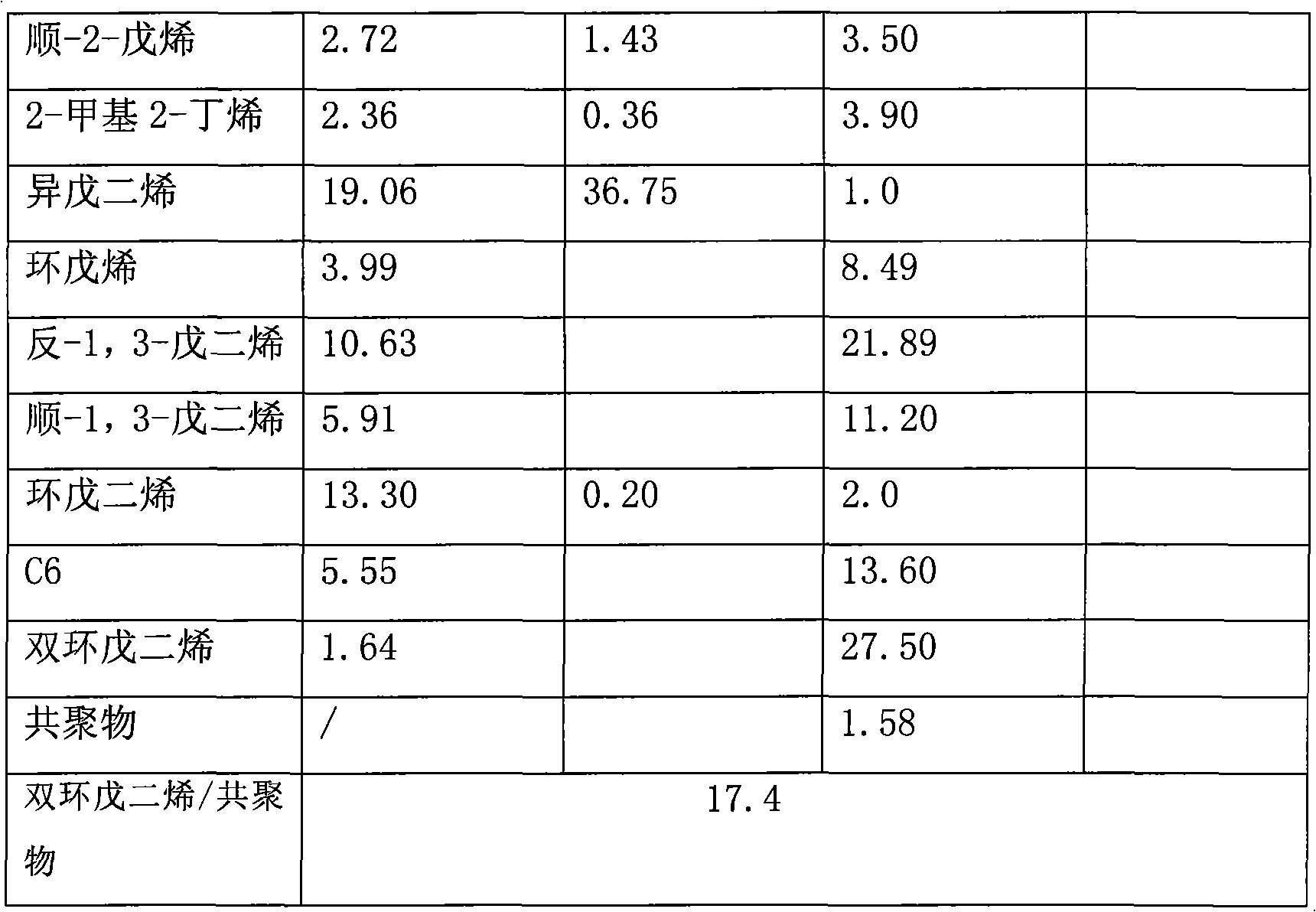

Embodiment 2

[0053] An emulsified packed tower with a diameter of 50mm and a metal Θ ring of Φ6*6*0.2 inside. The volume of the tower kettle is 1000ml and the height is 2.8 meters (equivalent to 40 theoretical plates). The middle part enters the reactive distillation tower, the feed temperature is controlled at 30°C, the tower top temperature is controlled at 56°C, the tower bottom temperature is increased to 90°C, the reflux ratio is controlled at 13, the tower top operating pressure is controlled at 0.20Mpa, and the cracking C5 The isoprene in the distillate is separated from the top of the tower together with other low-boiling point hydrocarbons through rectification, and the isoprene is separated in the extraction tower; and the cyclopentadiene in the feed is dimerized into dicyclopentadiene Together with piperylene and other high-boiling hydrocarbons, it is discharged from the bottom of the tower and sent to the piperylene tower and the dicyclopentadiene tower to obtain the product. T...

Embodiment 3

[0057] An emulsified packed tower with a diameter of 50mm and a metal Θ ring of Φ6*6*0.2 inside. The volume of the tower kettle is 1000ml and the height is 5.5 meters (equivalent to 77 theoretical plates). The middle part enters the reactive distillation tower, the feed temperature is controlled at 30°C, the tower top temperature is controlled at 56°C, the tower bottom temperature is increased to 90°C, the reflux ratio is controlled at 8, the tower top operating pressure is controlled at 0.20Mpa, and the cracking C5 The isoprene in the distillate is separated from the top of the tower together with other low-boiling point hydrocarbons through rectification, and the isoprene is separated in the extraction tower; and the cyclopentadiene in the feed is dimerized into dicyclopentadiene Together with piperylene and other high-boiling hydrocarbons, it is discharged from the bottom of the tower and sent to the piperylene tower and the dicyclopentadiene tower to obtain the product. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com