Rotator blade and small electric instrument having rotator blade

A technology of rotating cutter head and cutter head, which is applied in metal processing and other directions, can solve the problems of cracking of electrical insulation film, low yield rate of cutting blade, and poor yield rate, etc., to achieve improved strength, increased cutting opportunities, and efficient beard cutting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

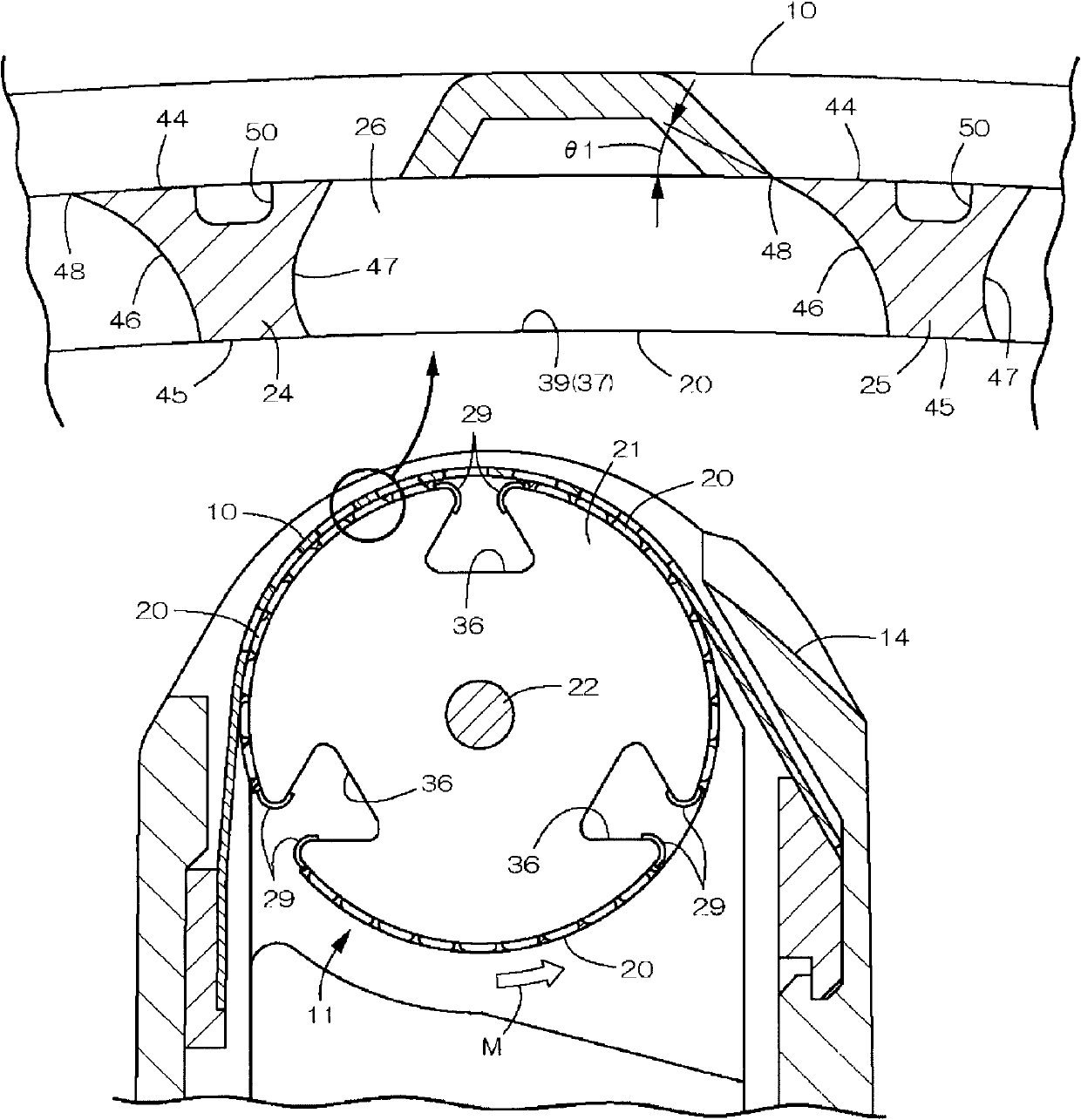

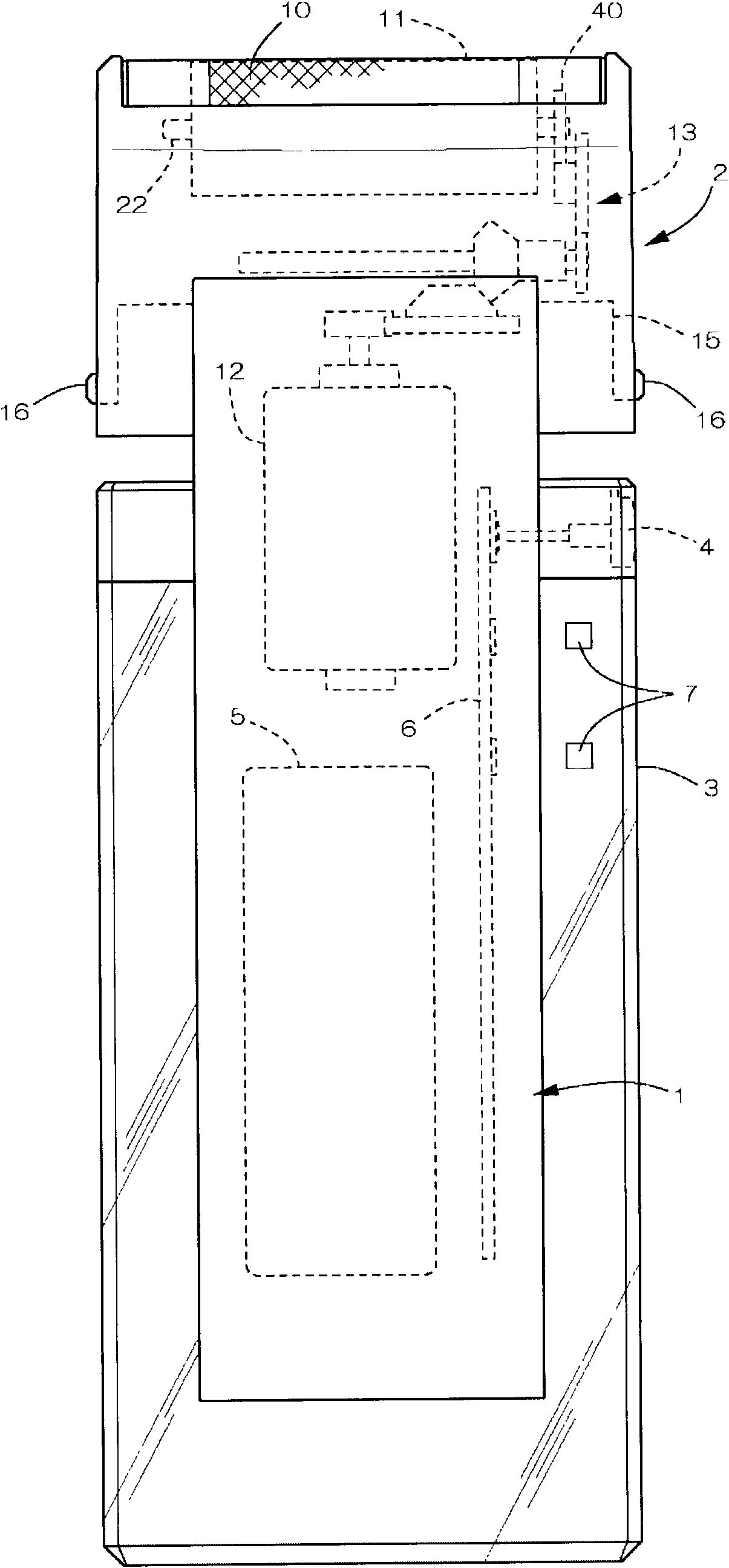

[0063] Figure 1 to Figure 11 An example in which the rotary head of the present invention is used for an inner head of a rotary electric shaver is shown. exist figure 2 Among them, the electric shaver includes: a main body 1, a head 2 supported by the main body 1, an outer frame 3 mounted on the main body 1, a shaving unit (not shown) disposed on the rear side of the main body 1, and the like. The outer frame 3 doubles as a decorative frame, and cooperates with the main body 1 to form a handle of the electric shaver. On one upper end of the outer frame 3, a switch button 4 for turning the motor 12 on and off is provided.

[0064] A rechargeable battery 5 and a circuit board 6 are installed inside the main body 1, and a switch for switching operation by the above-mentioned switch button 4, an LED for a display lamp 7, and a circuit composed of a control circuit and a power supply circuit are installed in the circuit board 6. electronic components, etc.

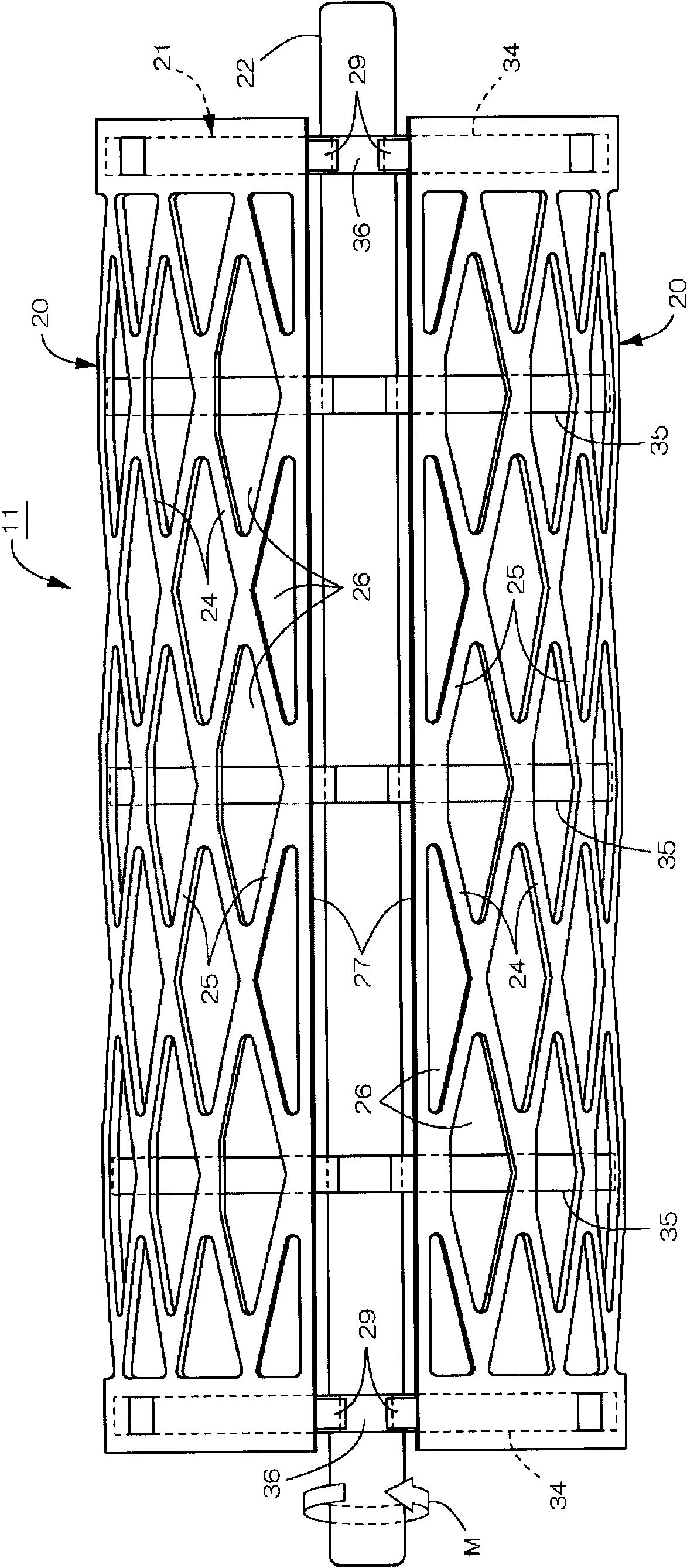

[0065] In head 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com