Automatic drill machine and processing technology thereof

An automatic drilling machine and processing technology, which is applied to metal processing equipment, components of boring machines/drilling machines, and manufacturing tools, etc., can solve problems such as easy damage of drill bit fixtures, troublesome, tools stuck in tool chucks, etc., and achieve fast tool change. , Reasonable process, convenient manufacturing and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

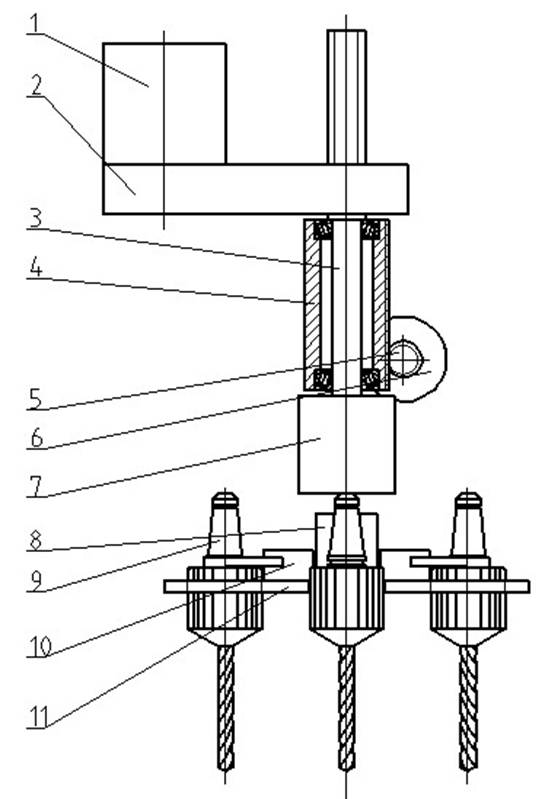

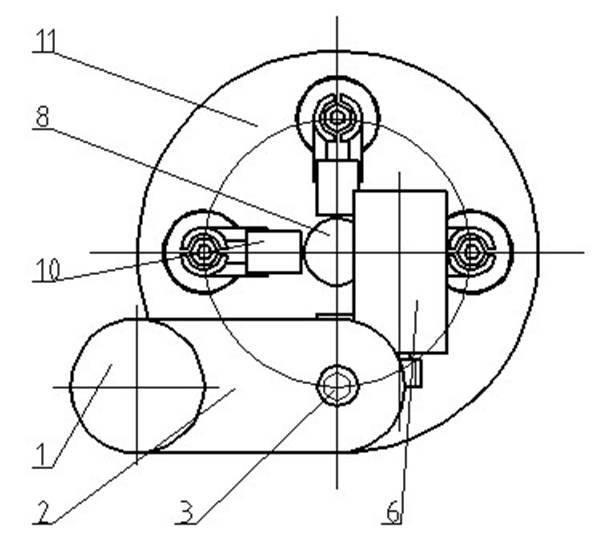

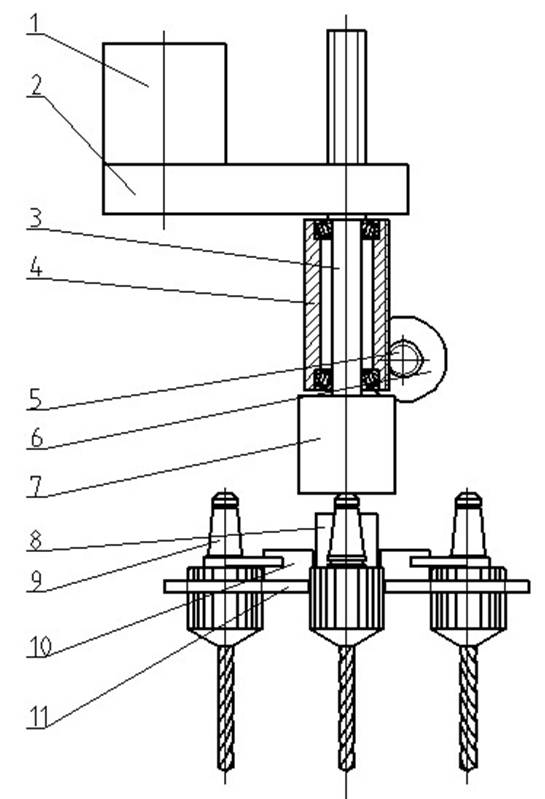

[0015] like figure 1 , figure 2 shown.

[0016] An automatic drilling machine, comprising: a controllable speed spindle motor 1, a gearbox 2, a spindle 3, a spindle cover 4, a gear 5, a controllable speed control angle lifting motor 6, a pneumatic automatic clamp 7, a controllable speed control angle disc motor 8. Tool chuck 9, manipulator 10, disc 11, tool structure.

[0017] An automatic drilling machine, the speed-controllable spindle motor 1 of the automatic drilling machine is connected to the main shaft 3 through a gearbox 2, and the upper end of the main shaft 3 is connected to the output shaft of the gearbox 2 through a spline, so that the main shaft 3 is in a rotating state The vertical direction feed movement below, the main shaft cover 4 is fixedly connected with the frame, the main shaft 3 realizes the relative rotation with the main shaft cover 4 through the bearing, and the controllable speed control angle lifting motor 6 drives the main shaft cover 4 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com