Coating device and method for forming pole piece of lithium battery

A coating method and technology of a coating device, which are applied in the direction of a device for coating liquid on a surface, a coating, etc., can solve problems such as uneven distribution of coatings, achieve uneven distribution of coatings, improve stability, and improve The effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

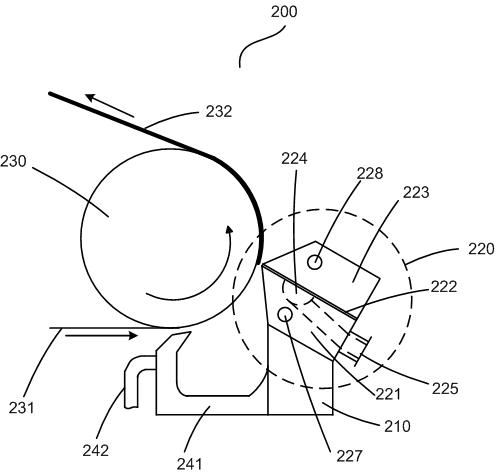

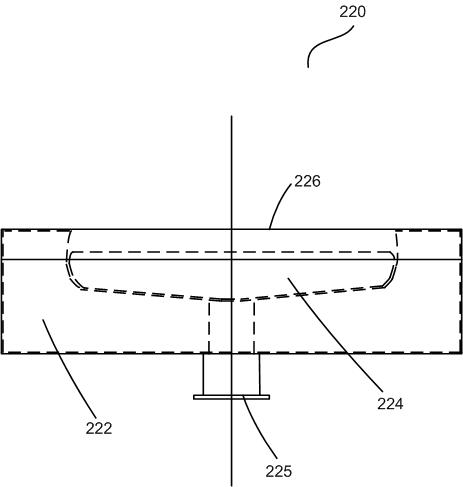

[0049] provide as figure 2 Coating apparatus 200 is shown. Wherein, the coating roller 230 is used for pulling the base material 231, and the material of the base material 231 is aluminum foil, and its width is 420 mm. The exit width of the slit nozzle 226 is 400 mm, the exit height is 0.7 mm, and the distance between the exit of the slit nozzle 226 and the surface of the substrate 231 is 0.2 mm. The feeding device that is connected with the slurry inlet 225 provides the mixed positive electrode slurry containing the iron disulfide active material to the slurry cavity 224, and provides a pressure of 7.5 PSI, so that the slurry passes through the narrow cavity from the slurry cavity 224. The outlet of the slit nozzle 226 is extruded and coated on the surface of the substrate 231 drawn by the rotating coating roller 230 , thereby forming a coating layer 232 .

Embodiment 2

[0051] In this embodiment, on the basis of Embodiment 1, the slurry chamber 224 is kept warm by adopting a water bath jacket arranged outside the slurry chamber 224 and formed by connecting the lower water bath jacket 227 and the upper water bath jacket 228 through hoses. The temperature was maintained at 30°C, and the coating process was completed.

Embodiment 3

[0053] In this embodiment, on the basis of Embodiment 1, vacuum assist technology is adopted, and a vacuum pump is used to evacuate the closed space enclosed by the vacuum tank 241, the tank side plate, the coating mold 220 and the coating roller 230 through the vacuum pipeline 242 , by adjusting the value of the efficiency utilization rate of the vacuum pump, the vacuum degree is adjusted to 90 Torr, and the coating process is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com