Preparation method of catalyst for combining pyridine

A catalyst and pyridine technology, applied in the field of catalysis, can solve the problems of short catalyst life and long operation period, and achieve the effects of less equipment investment, no three wastes, and improved life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

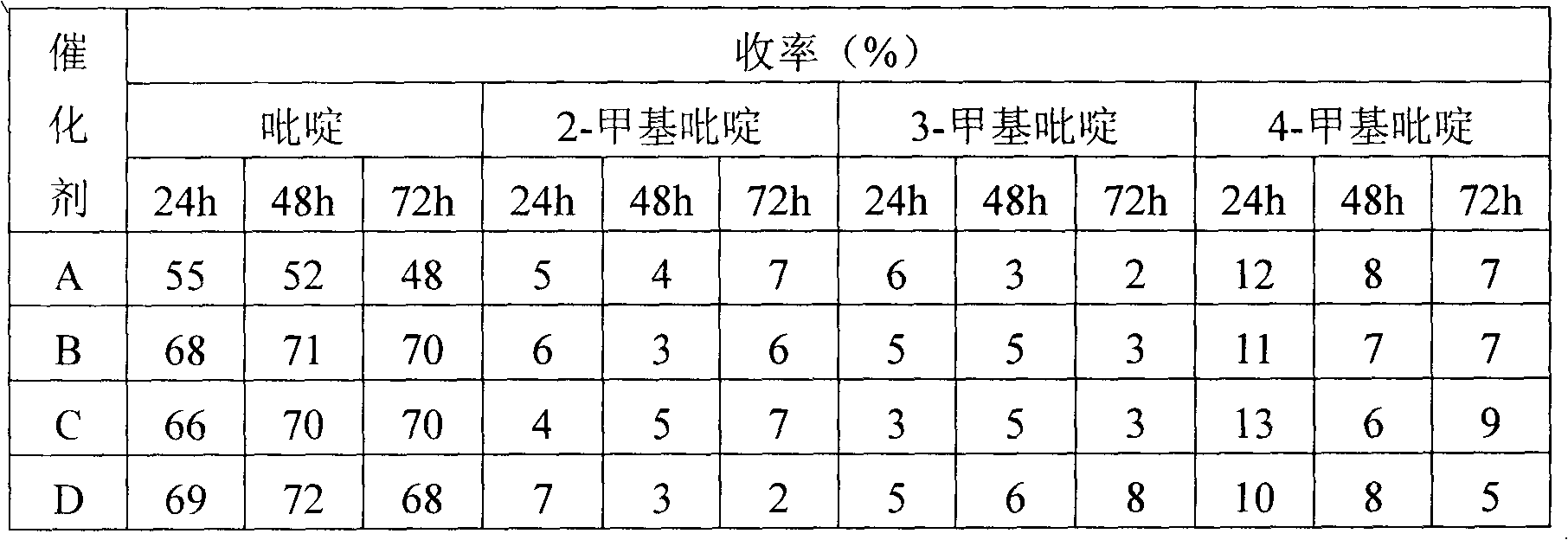

Embodiment 1

[0018] Take a certain amount of aluminum sulfate and sodium hydroxide solution to neutralize to obtain alumina hydrate, take a certain amount of lead nitrate, lanthanum nitrate, and cerium nitrate and add it to the alumina hydrate for beating and spray drying, and then calcined in a muffle furnace at 550°C Catalyst A in which lead, lanthanum, and cerium accounted for 2.5%, 0.4%, and 0.4% of alumina were prepared in 6 hours.

Embodiment 2

[0020] Take a certain amount of aluminum sulfate and sodium hydroxide solution to neutralize to obtain alumina hydrate, take a certain amount of potassium nitrate, lead nitrate, lanthanum nitrate, and cerium nitrate and add it to the alumina hydrate for beating and spray drying, and then pass through a muffle furnace Calcined at 550°C for 6 hours to prepare catalyst B in which potassium, lead, lanthanum and cerium accounted for 0.2%, 2.5%, 0.4% and 0.4% of alumina respectively.

Embodiment 3

[0022] Take a certain amount of aluminum sulfate and sodium metaaluminate solution to neutralize to obtain alumina hydrate, take a certain amount of potassium nitrate, lead nitrate, lanthanum nitrate, and cerium nitrate and add it to the alumina hydrate for beating and spray drying, and then pass through muffle Calcined in a furnace at 550°C for 6 hours to prepare catalyst C in which potassium, lead, lanthanum and cerium accounted for 0.2%, 2.5%, 0.4% and 0.4% of alumina respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com