Fuel cell module with water and thermal management capability

A technology of fuel cells and fuel cell stacks, which is applied in the direction of fuel cells, fuel cell additives, electrolyte treatment of solid electrolyte batteries, etc., and can solve problems such as unfavorable fuel cells, entering an ideal working state, and modules without water and heat management functions , to improve the stability of the

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

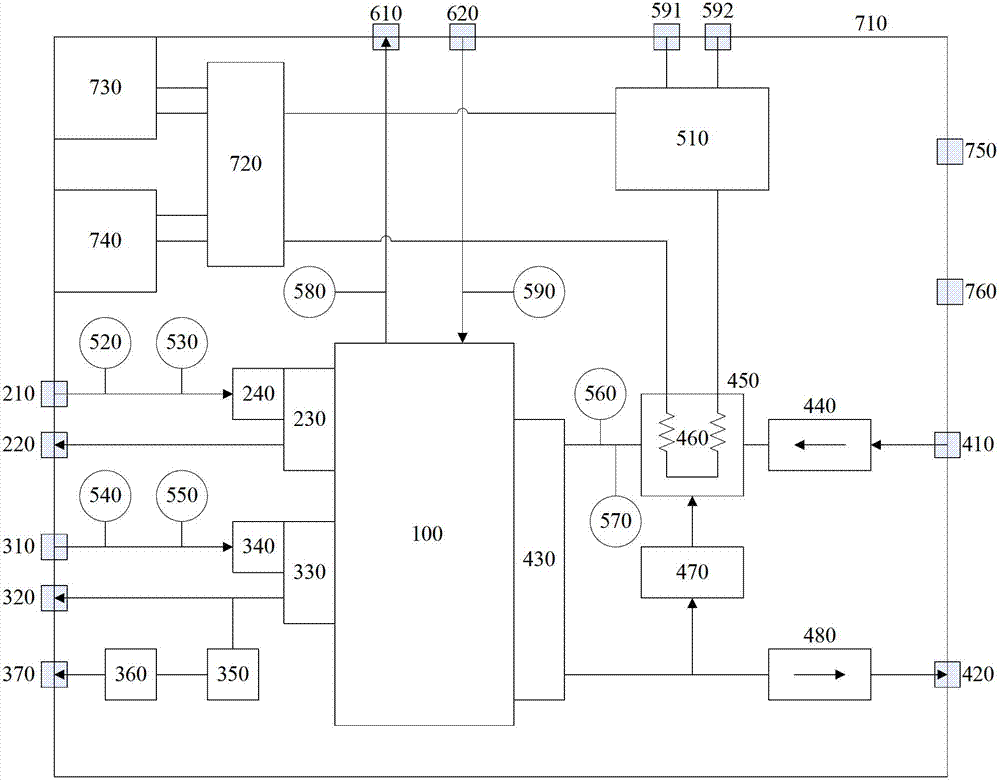

[0032] The embodiment is a 40kw fuel cell module with hydrothermal management capabilities.

[0033] There are two 20kw fuel cell stacks, each has 150 sections, the operating pressure is less than 100kpa, the decay rate Vt is 10mV / h, the air side resistance index is 20kpa50Nm3 / h, the hydrogen side resistance index is 25kpa10Nm3 / h .

[0034] The air circuit, hydrogen circuit and cooling medium circuit are connected in parallel, and the power output is connected in parallel, such as Picture 9 As shown, 1001 and 1002 are fuel cell stacks. The fuel cell stack 1001 air inlet 2301 is connected to the fuel cell stack 1002 air path inlet 2302 through the air distribution unit 230, and the fuel cell stack 1001 air outlet 2303 is connected to the fuel cell through the air distribution unit 230 The stack 1002 air path outlet 2304 is connected, the fuel cell stack 1001 hydrogen inlet 3301 is connected to the fuel cell stack 1002 hydrogen path inlet 3302 through the hydrogen distribution unit 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com