Sealing device for trolley of sintering circular cooler

A technology for sintered ring coolers and sealing devices, which is applied to engine sealing, mechanical equipment, engine components, etc., can solve the problems of difficult maintenance of sealing plates, achieve the effects of reducing maintenance difficulty, improving high temperature resistance, and improving sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

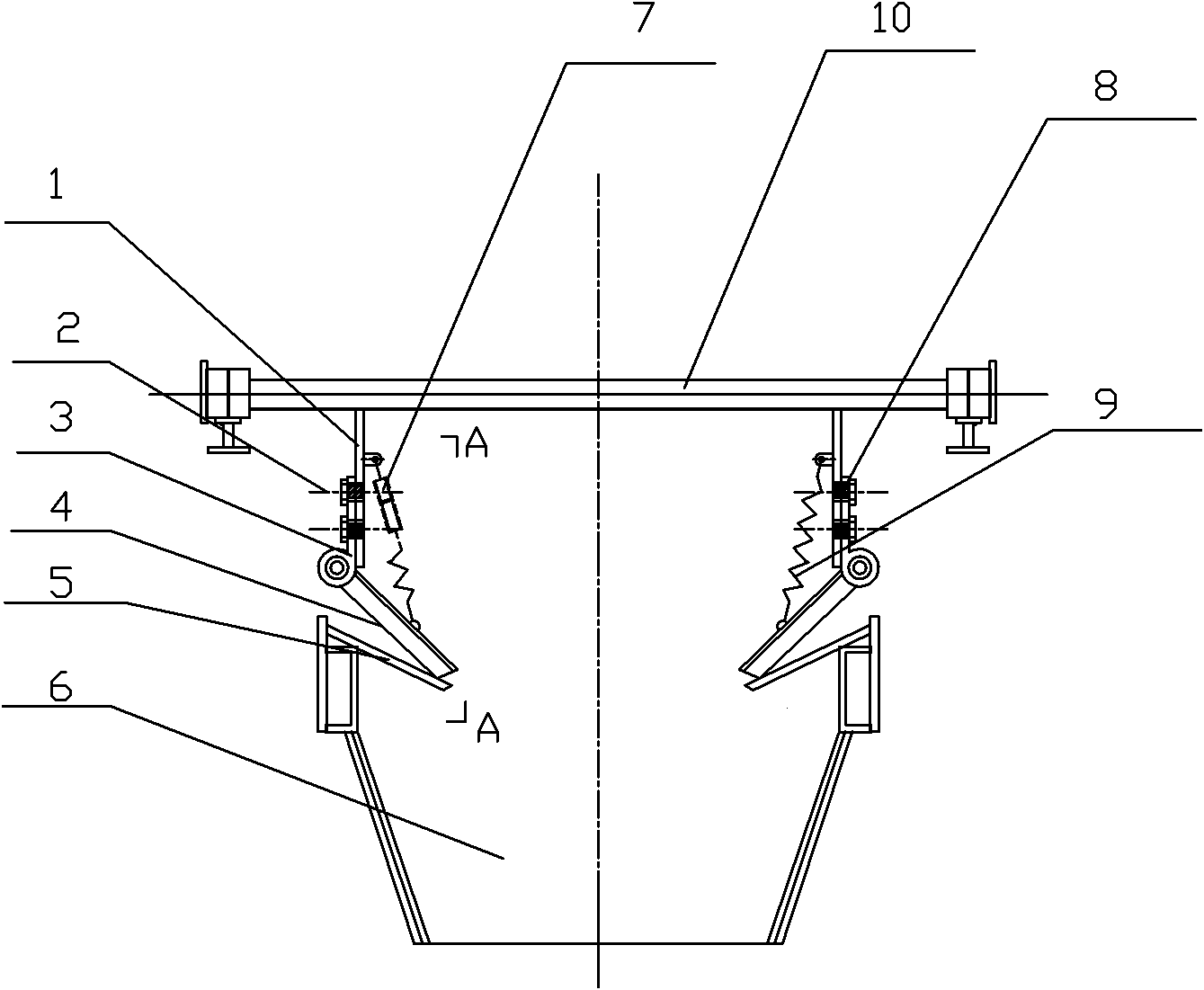

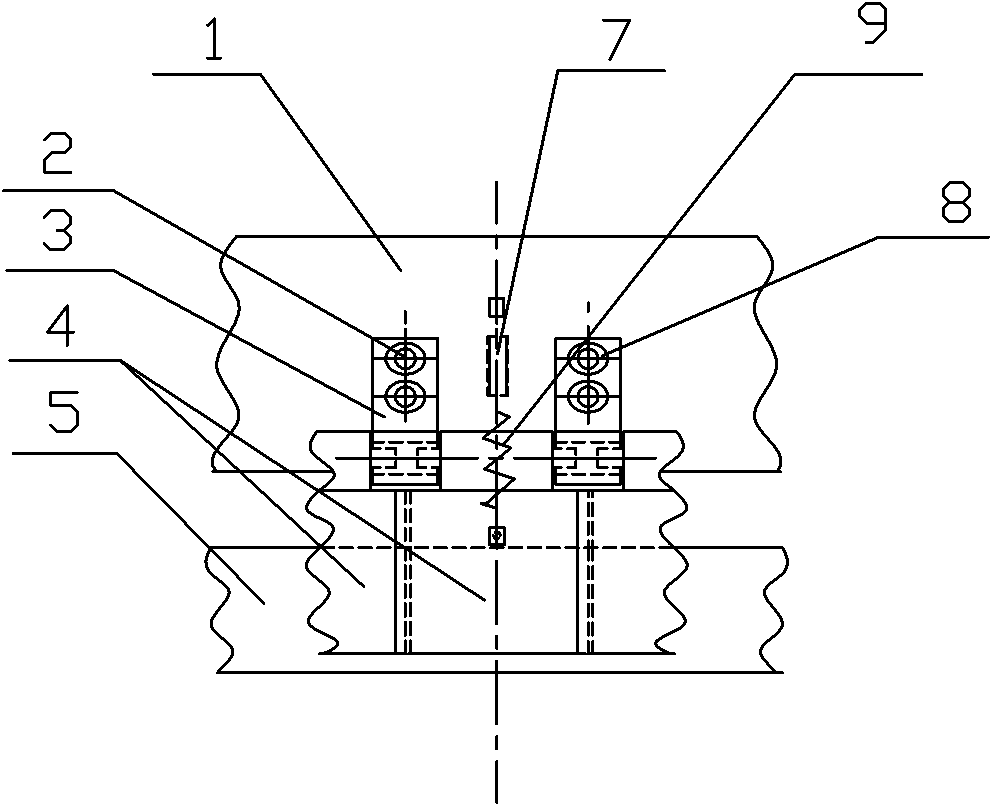

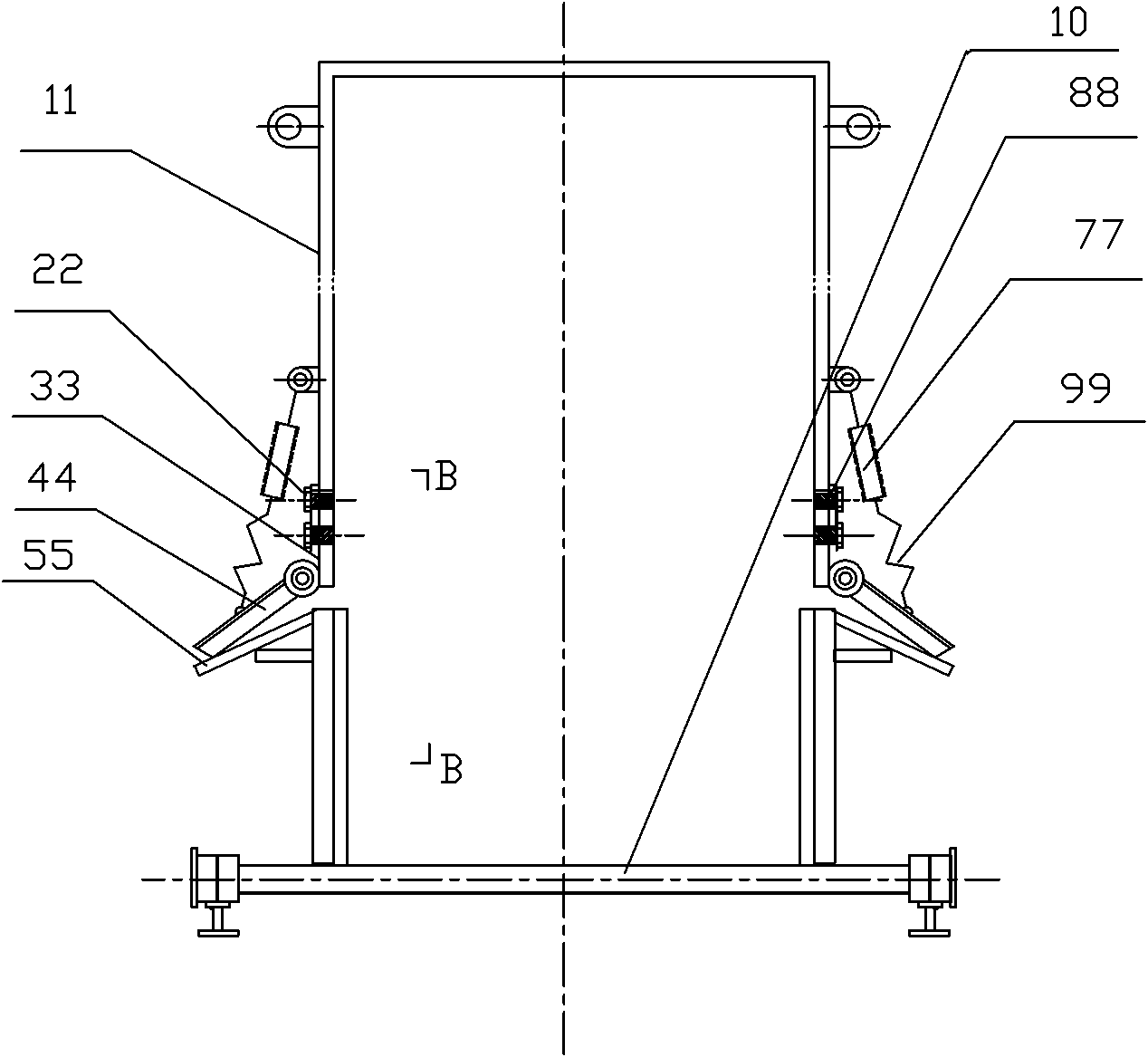

[0027] The present invention will be further explained below in conjunction with the drawings.

[0028] Such as figure 1 with figure 2 As shown, the sealing device of the sintered ring cooler trolley of the present invention mainly includes the lower movable sealing plate 4 of the trolley, the lower movable sealing plate support seat 3, the lower movable sealing plate fastener of the trolley 2, the static air chamber Sealing plate 5, the lower movable sealing plate 4 of the trolley is fixed to the supporting base 3 of the lower movable sealing plate of the trolley through a pin or hinge. The other end of the lower movable sealing plate 4 of the trolley is suspended and can be rotated with the pin or hinge as the axis. Move, and then use fasteners 2 to fix the supporting seat 3 of the lower movable sealing plate of the trolley on the lower compartment plate 1 of the trolley. The static sealing plate 5 of the wind chamber is fixed on the wind chamber, and the front end of the stati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com