Volume variable additional air chamber of air spring

A technology of air spring and additional air chamber, which is applied in the field of parts and components, can solve the problems of easy leakage, pollution, and space occupation of hydraulic oil, and achieve the effect of eliminating oil supply equipment, simple overall structure, and good practical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

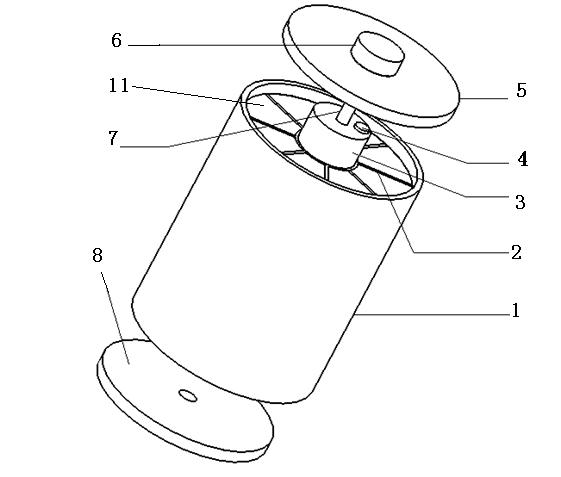

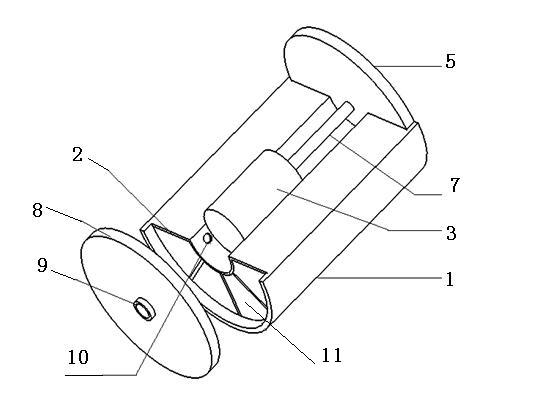

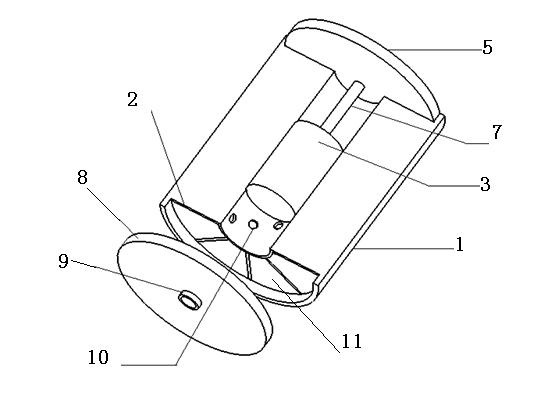

[0015] see figure 1 , the outside of the present invention is a cylindrical gas storage tank 1, and the gas storage tank 1 cavity is evenly divided into eight equal fan-shaped cylinder cells 11 with the same partition plate 2 in the circumferential direction of the gas storage tank 1 cavity. One side of each partition 2 is fixed on the inner wall of the gas storage tank 1, the other side of the partition 2 extends to the center of the gas storage tank 1, and the other side of the partition 2 is assembled into a closed cylinder at the center of the gas storage tank 1 Shaped cavity, that is, the side wall of the cylindrical cavity is made up of the other side of all the partitions 2. The airtight cylindrical cavity is used for installing the piston 3 and is closely matched with the piston 3, and the piston 3 can move up and down along the center line in the cylindrical cavity. The top of the piston 3 stretches out of the air storage tank 1, and a height sensor 4 is fixedly ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com