Flow compensation technology of digital frequency conversion metering pump

A technology of flow compensation and digital frequency conversion, which is applied in the field of metering pumps, can solve the problems of heavy fertilization workload, high cost of manpower and financial resources, etc., and achieve the effect of improving output accuracy and precise fluid dosing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

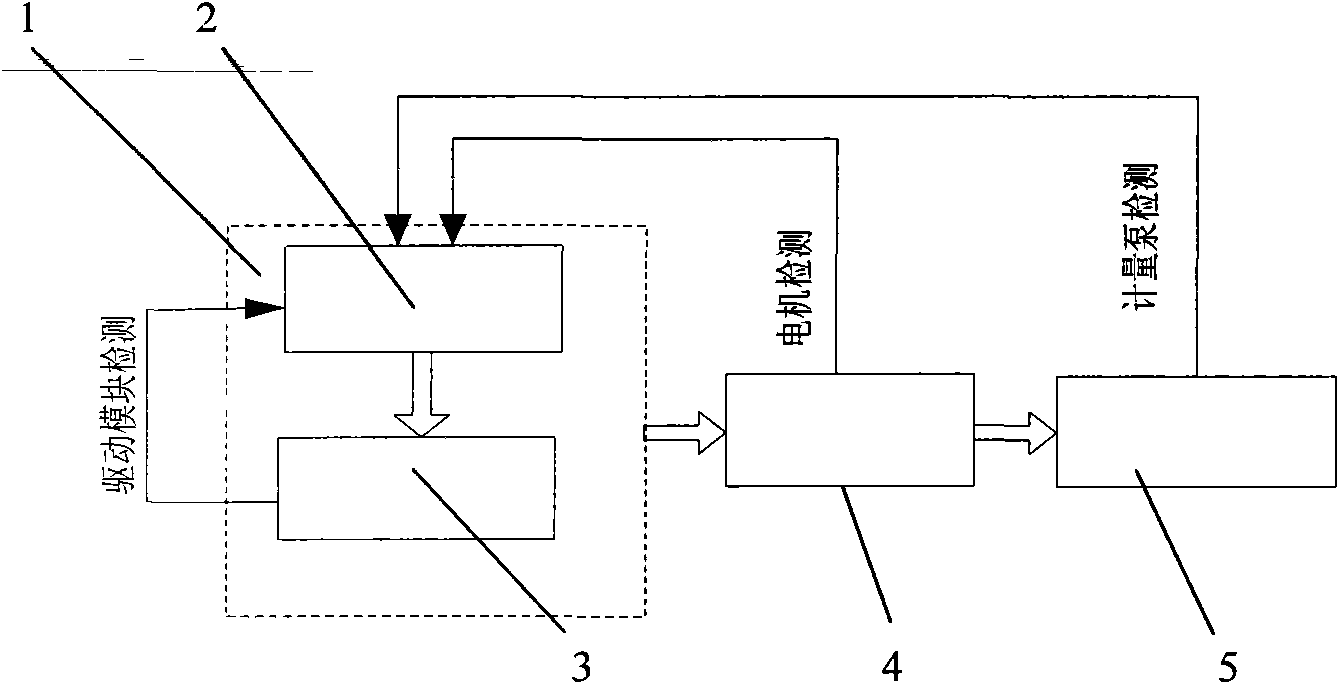

[0025] exist figure 1 Middle: The digital frequency conversion metering pump is composed of a special digital frequency converter 1, a three-phase asynchronous gear motor 2 and a reciprocating diaphragm metering pump 3. The dedicated digital frequency converter consists of a main control module 4 and a drive module 5 . By detecting information such as the temperature of the drive module 5 and whether it is overcut (overcurrent), the main control module 4 decides whether to take corresponding protection measures; through the speed detection components (parts) such as encoders or Hall devices, detect three-phase asynchronous The speed of geared motor 2 is used for closed-loop control. If there is no speed signal after starting the three-phase asynchronous geared motor 2, it indicates that there is a fault in the three-phase asynchronous geared motor 2 or a fault in the speed sensor, and the main control module 4 controls the drive module 5 to enter the protection state. If the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com