Two-section nonrising stem flat valve with switch indicator

A technology of indicators and flat valves, which is applied in the direction of wellbore/well valve devices, valve devices, wellbore/well components, etc., and can solve problems such as accelerated wear of parts, large valve caliber, and large cavity diameter of the valve body. Achieve the effects of reducing misalignment, increasing insertion depth, and opening and closing easily and quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

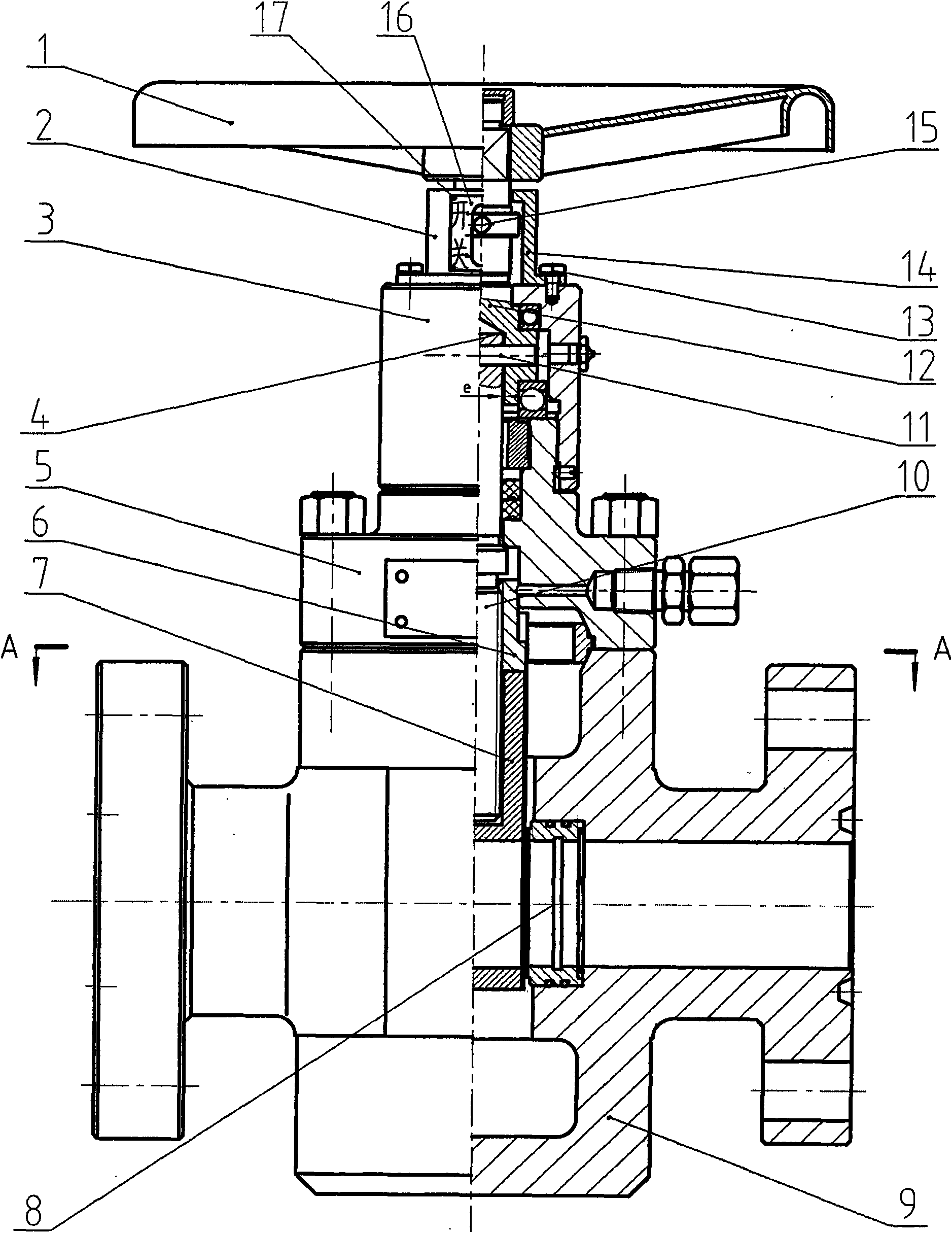

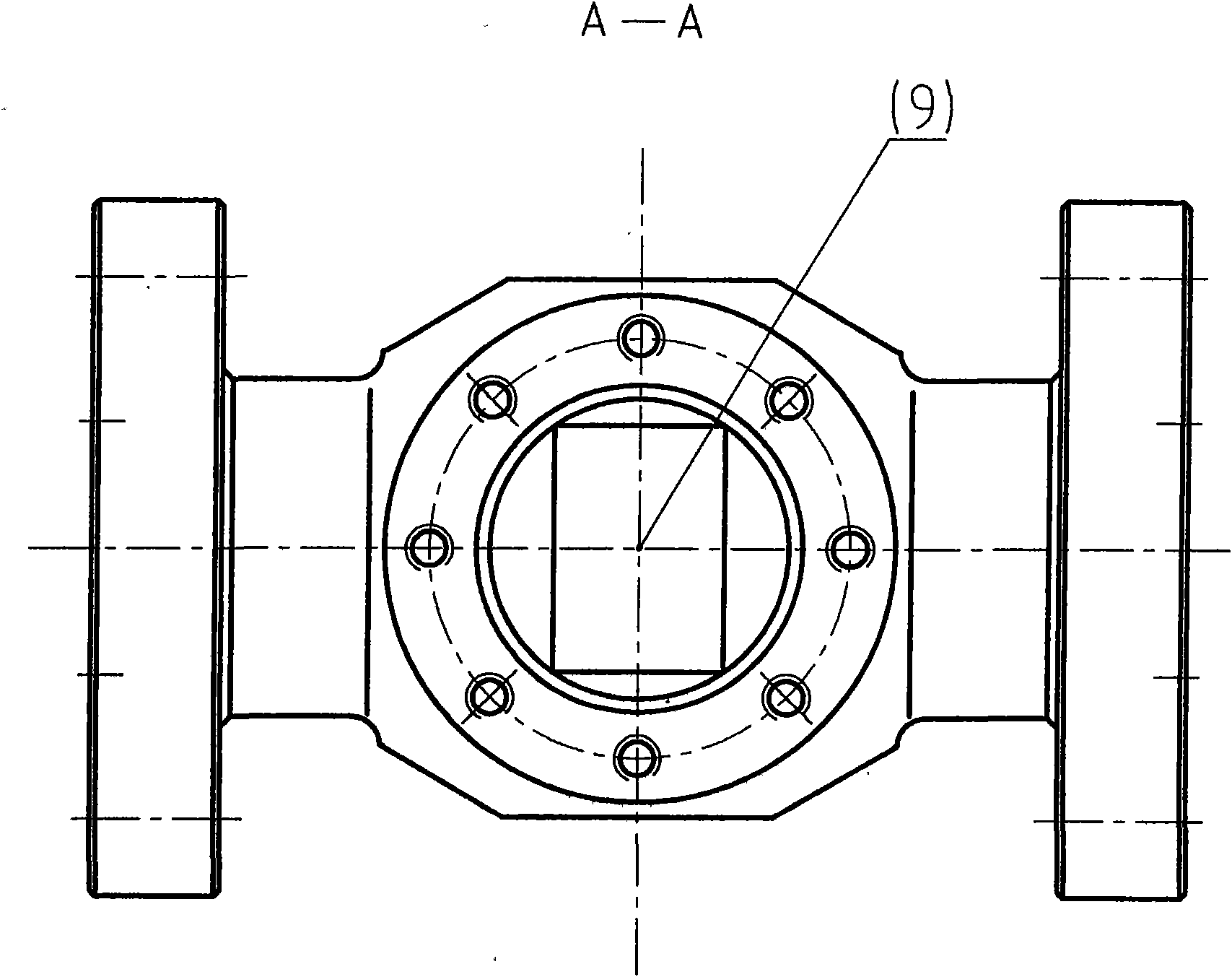

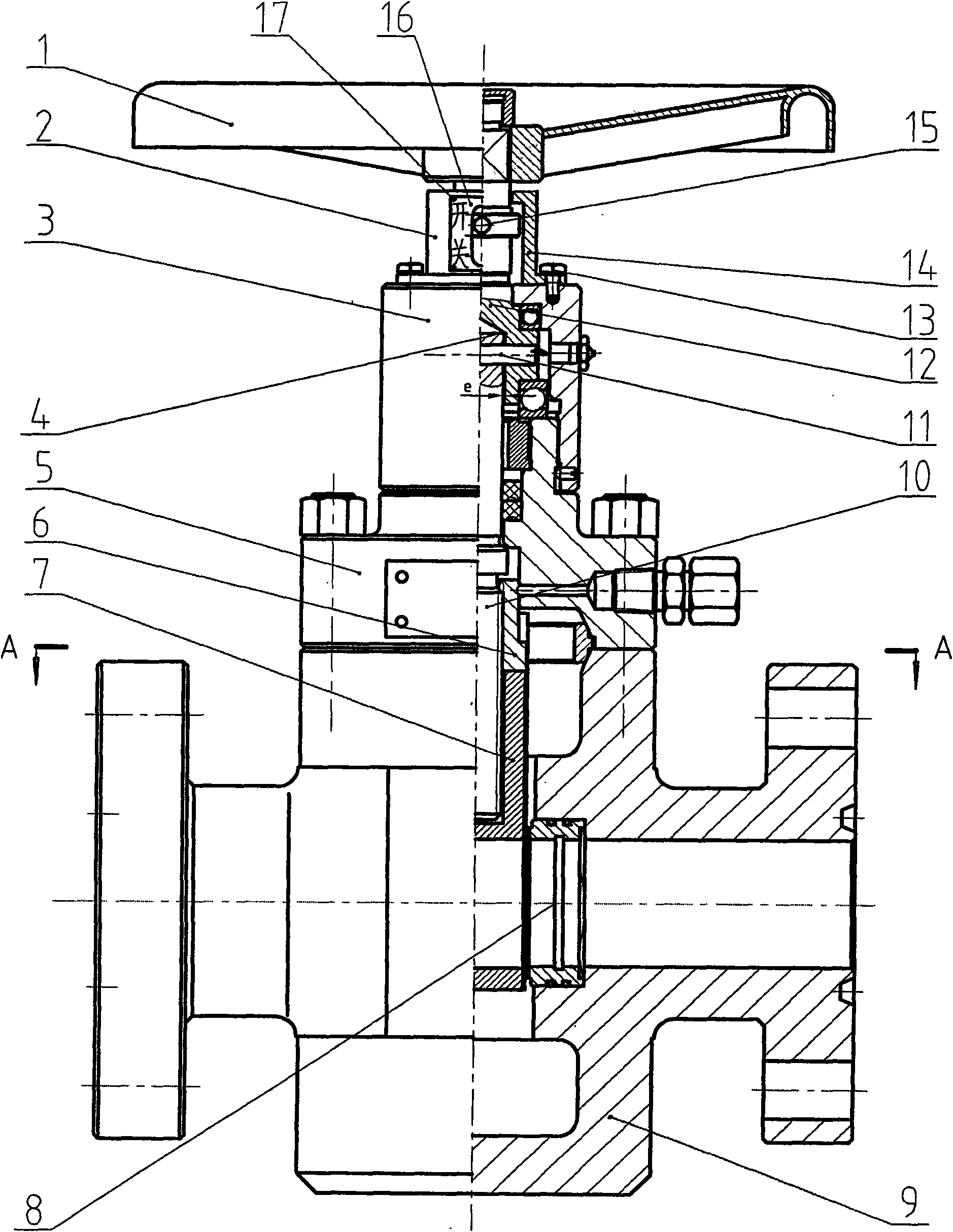

[0011] The present invention consists of a hand wheel assembly (1), a switch indicating part (2), a supporting rotating part (3), a valve stem part (4), a sealing lubricating part (5), a nut (6), a gate (7), Valve seat assembly (8) and valve body (9) are formed. One of its characteristics is: a valve stem part (4) is used to replace a valve stem part in the existing manual hidden rod flat plate valve. Valve stem part (4) is made up of lower section valve stem (10), cylindrical pin (11) and last section valve stem (12). The upper end of the upper valve rod (12) is processed with a screw head and a square prism, and a hand wheel assembly (1) is housed; the middle is a screw rod, and a nut pointer (15) in the switch indicating part (2) is housed; the diameter of the lower end is increased Thick, the periphery is processed into circular steps, and the interior is processed into blind holes; the peripheral circular steps are used to install and support the upper and lower bearings...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com