Square-tube inserting fitting, protecting window provided with same and manufacturing method thereof

A production method and technology of protective windows, which are applied in the direction of preventing war damage, etc., can solve problems such as connection failure, safety accidents, welding point oxidation, etc., and achieve the effects of stable and reliable connection, improved processing efficiency, and guaranteed connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

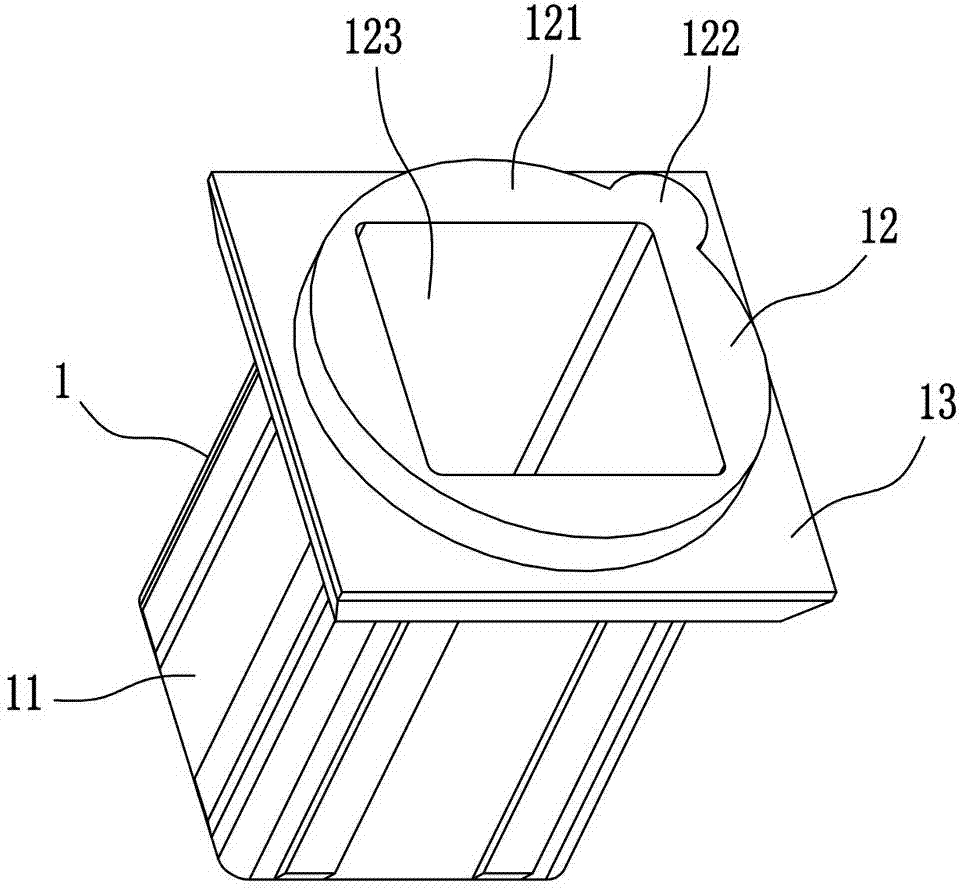

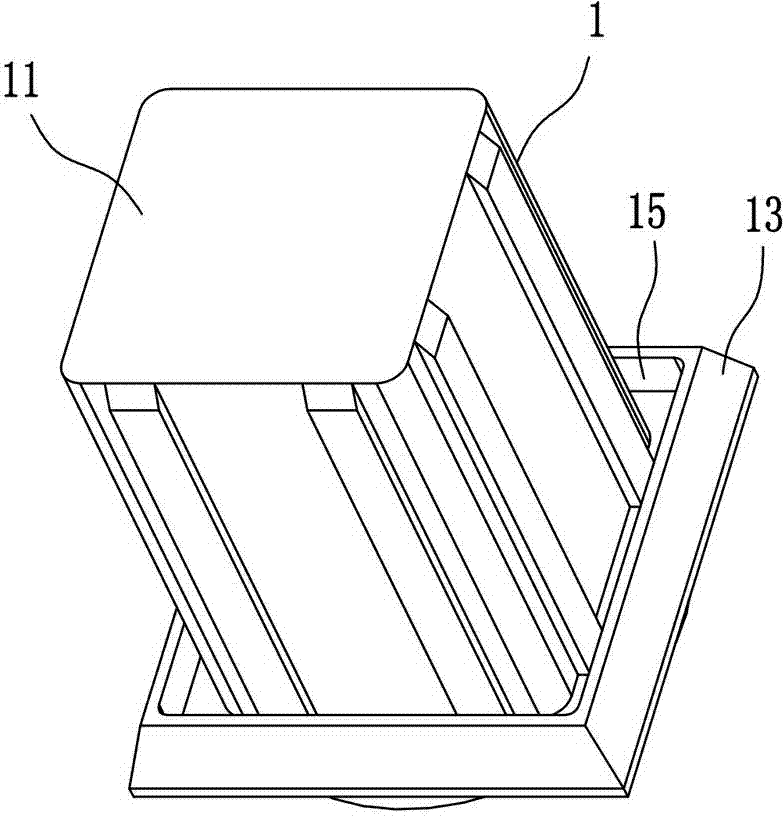

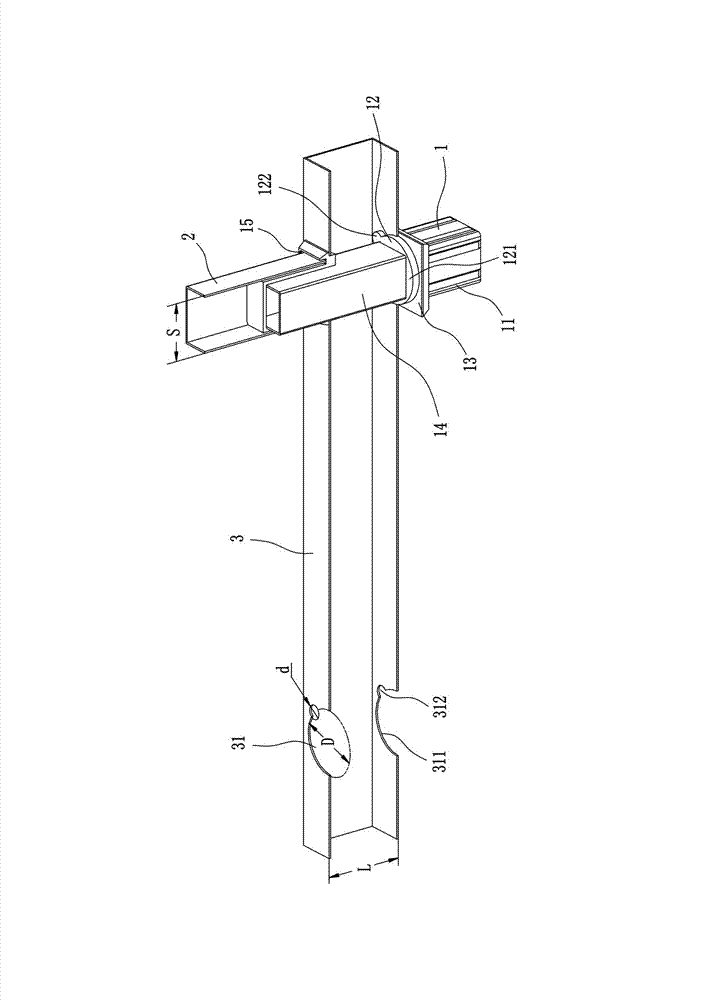

[0031] Figure 1 to Figure 3 It shows an embodiment of a plug-in fitting for connecting a thick square tube and a thin square tube according to the present invention. The plug-in fitting includes a fitting body 1, and one end of the fitting body 1 is a square plug-in part inserted into the thin square tube 2 11. The other end is the round plug-in part 12 plugged into the plug-in hole 31 provided on the thick square tube 3. A retaining ring 13 is provided between the square plug-in part 11 and the round plug-in part 12. Through the round plug-in The part 12 is connected to the thick square tube 3, and only a round hole needs to be drilled on the thick square tube 3 to cooperate with the round insertion part 12. Compared with the previous processing form that needs to punch a square hole on the thick square tube 3, the present invention adopts Drilling can be used to process the insertion hole 31 on the thick square tube 3 after the plug-in fittings, the drilling process yield i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com