Simulation teaching factory for preparing cyclohexane through benzene hydrogenation

A technology of simulation teaching and cyclohexane, applied in the fields of education, chemical technology and equipment, can solve the problems such as difficulty in ensuring safety and environmental protection, difficulty in transplanting production devices into teaching and training rooms, and difficulty in understanding and realization of students, so as to improve the Ability to analyze and solve problems, cultivate collaborative ability and team awareness, and enhance the effect of practical operation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

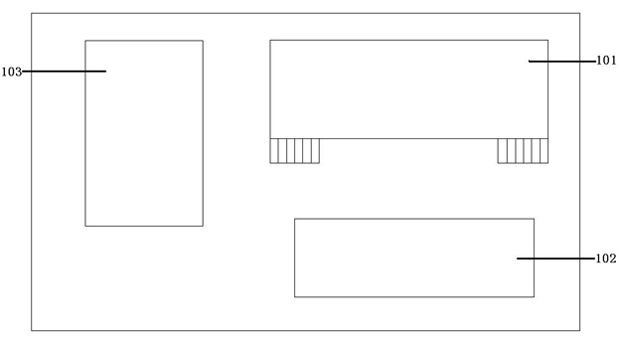

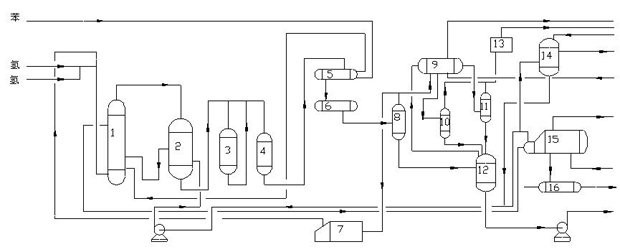

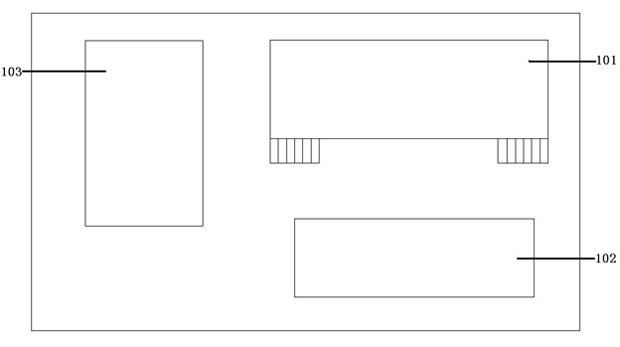

[0019] figure 1 It is a structural schematic diagram of the present invention; figure 2 It is a schematic diagram of the process flow of the present invention.

[0020] Such as Figure 1 to Figure 2 As shown, the simulation teaching factory for the hydrogenation of benzene to cyclohexane of the present invention includes a chemical plant construction area 101, an indoor operation area 102 and a teaching discussion area 103, wherein, the chemical plant construction area 101 is provided with small chemical plant, device Frame and chemical instrumentation (not shown in the figure), the device frame is an installation support frame, the small chemical device is arranged on the device frame, the chemical instrument is connected with each instrument in the small chemical device, and a control system is arranged in the indoor operation area 102 , the control system is connected with the above-mentioned small chemical equipment through signal cables, and the teaching discussion are...

Embodiment

[0022] Such as figure 2 As shown, this embodiment takes the construction of a simulation teaching factory for hydrogenation of benzene to cyclohexane as an example when the net height of the construction site is 3.8 meters (but not limited to this size), and its specific process is as follows:

[0023] The small chemical plants in chemical plant construction area 101 include benzene evaporation equipment, hydrogenation reaction equipment, desulfurization reaction equipment, condensation equipment, separation equipment, adsorption equipment and waste heat recovery equipment, among which benzene evaporation equipment, hydrogenation reaction equipment, desulfurization reaction equipment Equipment, condensation equipment, separation equipment, and adsorption equipment are connected in sequence. The benzene evaporation equipment includes a benzene evaporator 1 and a benzene preheater 5, the hydrogenation reaction equipment includes a pre-hydrogenation reactor 2, a post-hydrogenati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com