Screw pile used for seasonally frozen ground zone

A screw pile, seasonal technology, applied in the field of screw piles, can solve the problems of not being able to effectively prevent and control frozen soil damage, and achieve the effect of large bearing capacity, reduced size, and fast pile formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

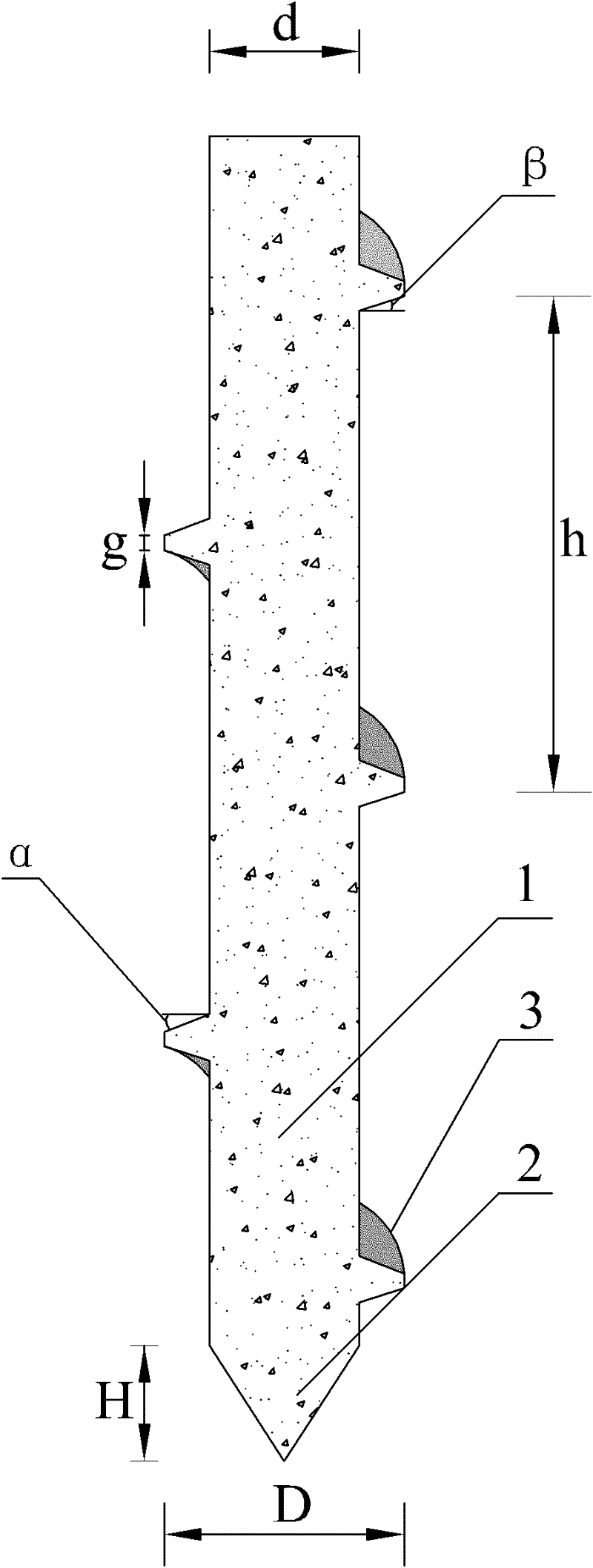

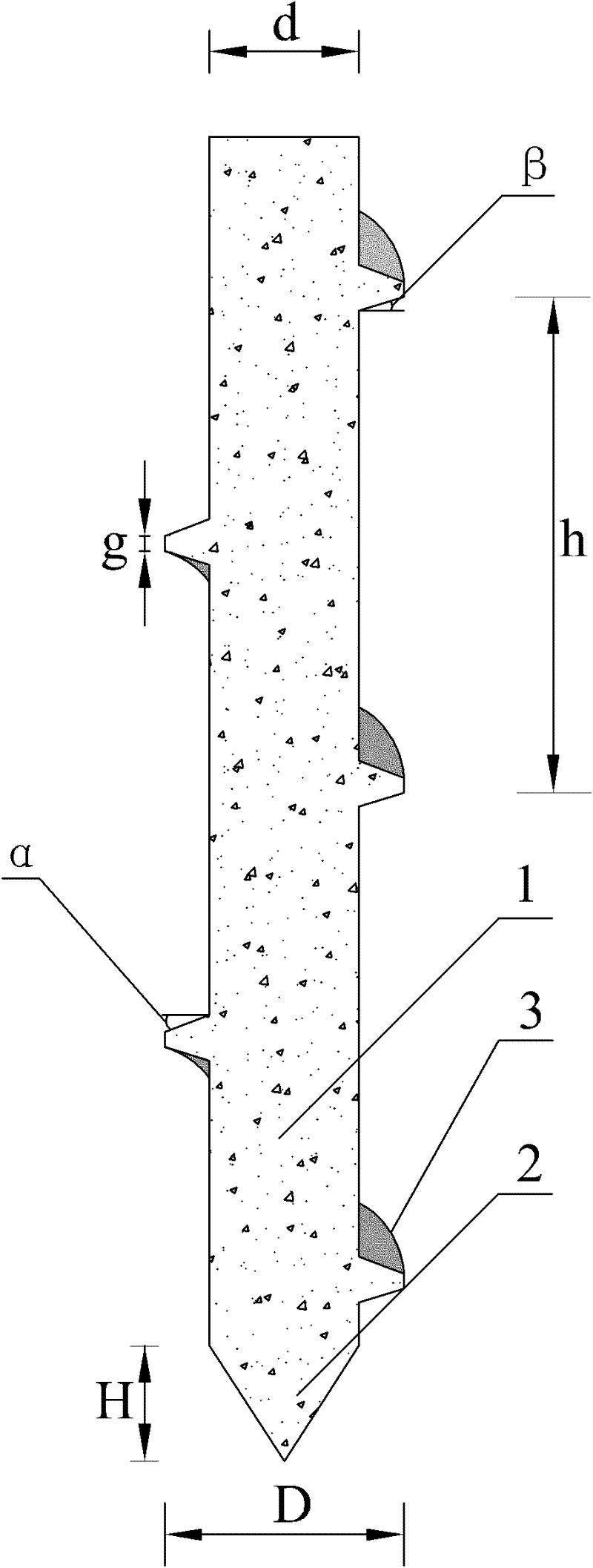

[0009] Specific implementation mode one: combine figure 1 Describe this embodiment, the screw pile of this embodiment comprises concrete pile body 1, concrete pile head 2 and concrete spiral blade 3, concrete pile body 1 is cylindrical, concrete pile head 2 is a cone, the bottom end surface of concrete pile body 1 It is affixed to the upper end surface of the concrete pile head 2 and the two are integrated, and the concrete spiral blade 3 is arranged on the outer wall of the concrete pile body 1, and the two are integrated, and the upward inclination angle α of the concrete spiral blade 3 is 15 to 45 °, the screw pitch h is 800 mm to 1000 mm, and the ratio of the diameter d of the concrete pile body 1 to the outer diameter D of the concrete spiral blade 3 is 0.5 to 0.7.

[0010] With the increase of the screw pitch, the vertical displacement value of the pile top under the action of the freezing pullout force of the screw pile increases continuously, based on the actual situat...

specific Embodiment approach 2

[0012] Specific implementation mode two: combination figure 1 Describe the present embodiment, the ratio of the diameter d of the concrete pile body 1 of the present embodiment and the outer diameter D of the concrete spiral blade 3 is 0.6, and the vertical displacement value of the frozen-drawn spiral pile is minimum at this moment, and it is in the seasonal permafrost region It can most effectively prevent the damage to buildings (structures) caused by frost heaving, thawing and settlement of frozen soil. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0013] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the thread thickness g of the concrete spiral blade 3 of this embodiment is 80 mm to 120 mm. This structure can most effectively prevent frost damage such as frost heaving and thawing of the frozen soil in areas with seasonally frozen soil. ) destruction of buildings. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com