Concrete pile forming device and construction method thereof

A technology for concrete piles and construction methods, applied in sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of complex construction, increased cost, and reduced work efficiency, and achieves good pile quality, high work efficiency, and low engineering cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

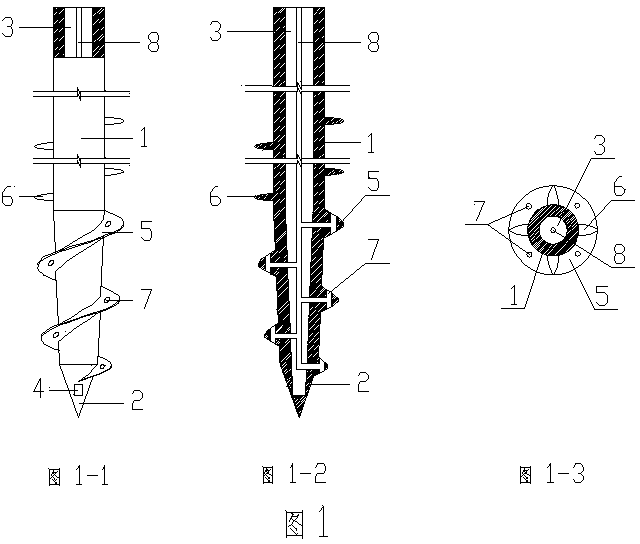

[0023] figure 1 It is the structural diagram of the pile forming device of the concrete pile of the present invention, as figure 1 As shown, the piling device includes a drill pipe 1 and a drill bit 2, the lower end of the drill bit 2 is provided with a discharge port 4, the inside of the drill pipe 1 is a hollow pipe 3 that can transport concrete, and the hollow pipe 3 is provided with a pipe that can transport cement slurry. Slurry pipe 8, the upper part of the outer wall of the drill pipe 1 is a straight rod, the middle part is provided with a plurality of stirring blades 6, and the lower part is provided with continuous helical blades 5. A plurality of slurry outlet holes 7 are arranged on the top, the slurry outlet holes 7 communicate with the slurry delivery pipe 8, and the hollow pipe 3 communicates with the discharge port 4 at the lower end of the drill bit 2 .

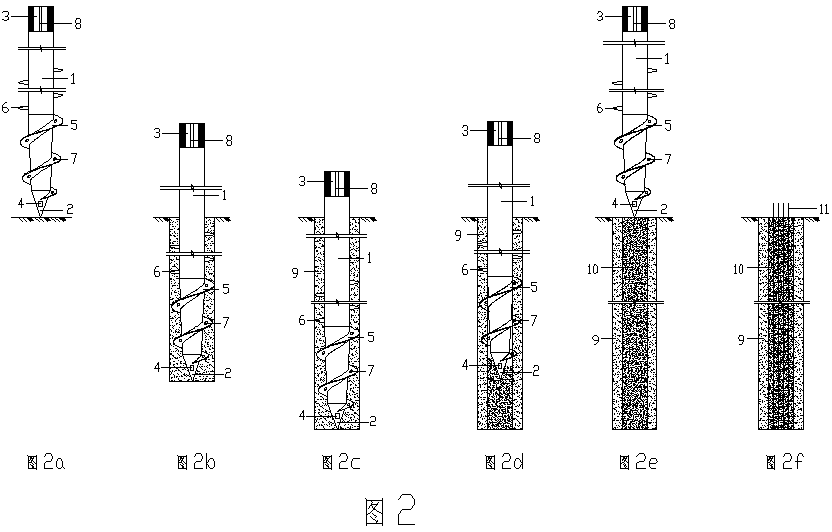

[0024] figure 2 It is the operation figure of the construction method of the concrete pile of an embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com