Side floating track bed and application thereof

A floating ballast bed and side-mounted technology, applied in the field of rail transit, can solve the problems that the spring vibration isolator cannot be lifted, installed or repaired and replaced, restricts the popularization and application of the side-mounted floating ballast bed, and affects the normal operation of rail transit, etc., reaching the peak Improve the installation and daily maintenance convenience, broad market application prospects, and shorten the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

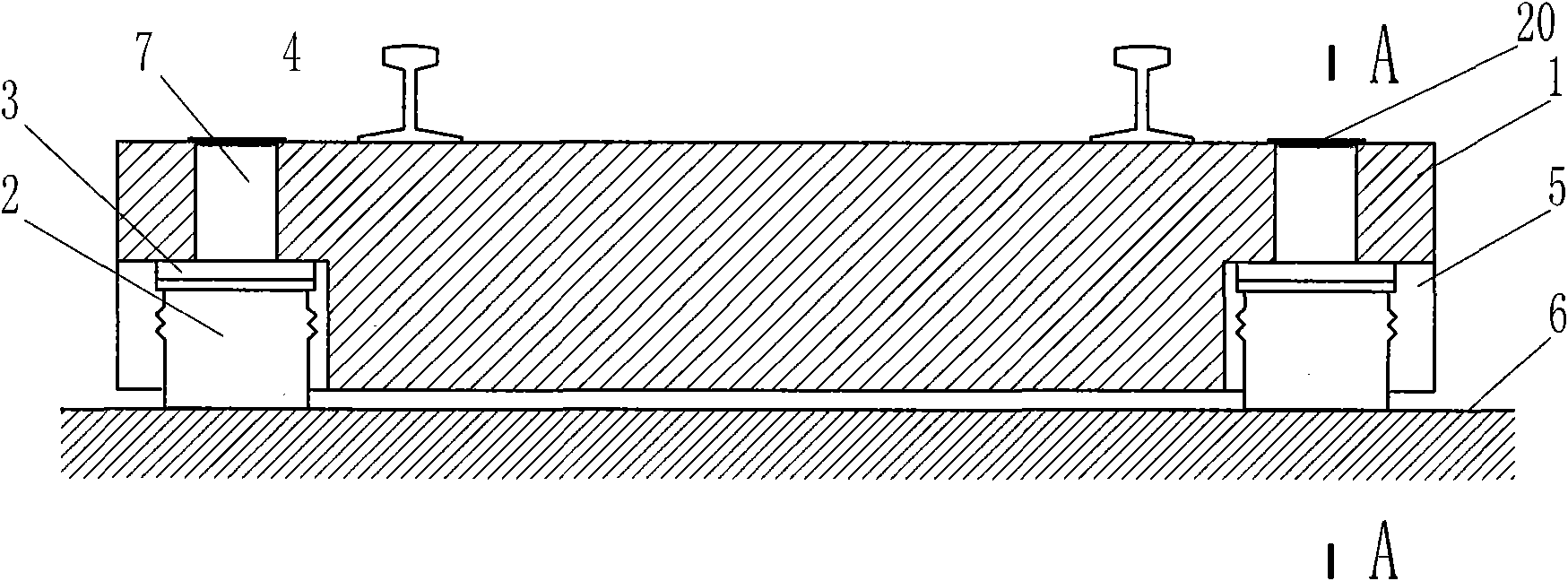

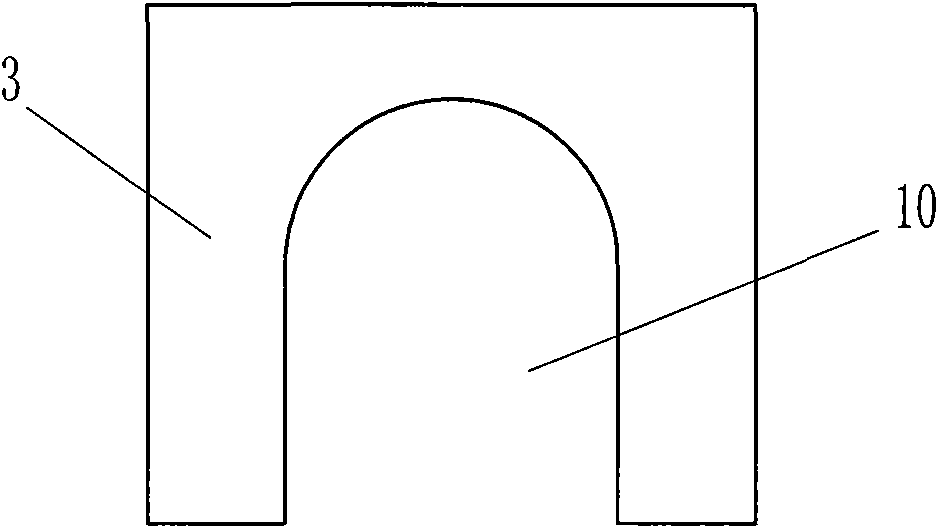

[0062] Such as figure 1 , figure 2 , image 3 The side-mounted floating ballast bed of the present invention as shown includes a floating plate 1, an elastic vibration isolator 2 and a gasket 3. The elastic vibration isolator 2 is arranged in the side groove 5 on the lower side of the floating plate 1, and passes through the gasket. 3 Supported on the floating plate 1, the lifting through hole 7 is set on the floating plate 1 corresponding to the position where the elastic vibration isolator 2 is placed, and the gasket 3 is also provided with an opening 10. 7 corresponds. The elastic vibration isolator 2 used in this example is a helical steel spring vibration isolator with silicone oil liquid damping material inside. The track structure 4 is arranged on the floating plate 1, where the track structure may include auxiliary elements such as sleepers and fasteners in addition to steel rails. The upper and lower surfaces of the elastic vibration isolator 2 are provided with ...

Embodiment 2

[0070] Such as Figure 5 , Figure 6 The difference between the side-mounted floating ballast bed of the present invention and the first embodiment is that the upper and lower surfaces of the elastic vibration isolator 2 are respectively provided with anti-slip backing plates 9 and conical protrusions to prevent its horizontal displacement. 8. Therefore, it can effectively ensure that the elastic vibration isolator 2 will not be displaced horizontally during the working process. In order to further save materials, simplify the construction process and reduce costs, in this example, a continuous side groove is set on the floating plate 1 5. The elastic vibration isolator 2 is correspondingly arranged in the position corresponding to the jacking through hole 7 in the side groove, and the elastic vibration isolator 2 adopted in this example is a rubber spring vibration isolator. The jacking and maintenance methods of the side-mounted floating ballast bed described in this examp...

Embodiment 3

[0073] Of course, in order to further reduce the cost, under the condition that the strength requirements are met, shallower side grooves 5 can be set on the floating plate of the side-mounted floating ballast bed of the present invention, such as Figure 7 , Figure 8 As shown, the difference from the second embodiment is that only part of the gasket 3 is placed in the side groove 5, and the anti-skid pad 9 and the conical protrusion 8 can well prevent the elastic vibration isolator 2 from Horizontal displacement occurs, so the same vibration isolation effect and function can also be achieved. In addition, for the case of setting multiple gaskets 3, for the sake of safety, fasteners can be used to connect the multiple gaskets together, or even directly connected to the elastic vibration isolator with fasteners.

[0074] It should be pointed out that since only a very shallow side groove 5 is provided on the floating plate 1, it is impossible to place the elastic vibration is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com