Method for extracting and preparing camellia polysaccharide from camellia and application of camellia polysaccharide

A technology of camellia polysaccharides and tea polysaccharides, which is applied in the field of medicinal applications of the camellia polysaccharides, can solve the problems that the research on the development and utilization of tea tree flowers has not yet been fully carried out, and achieve the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

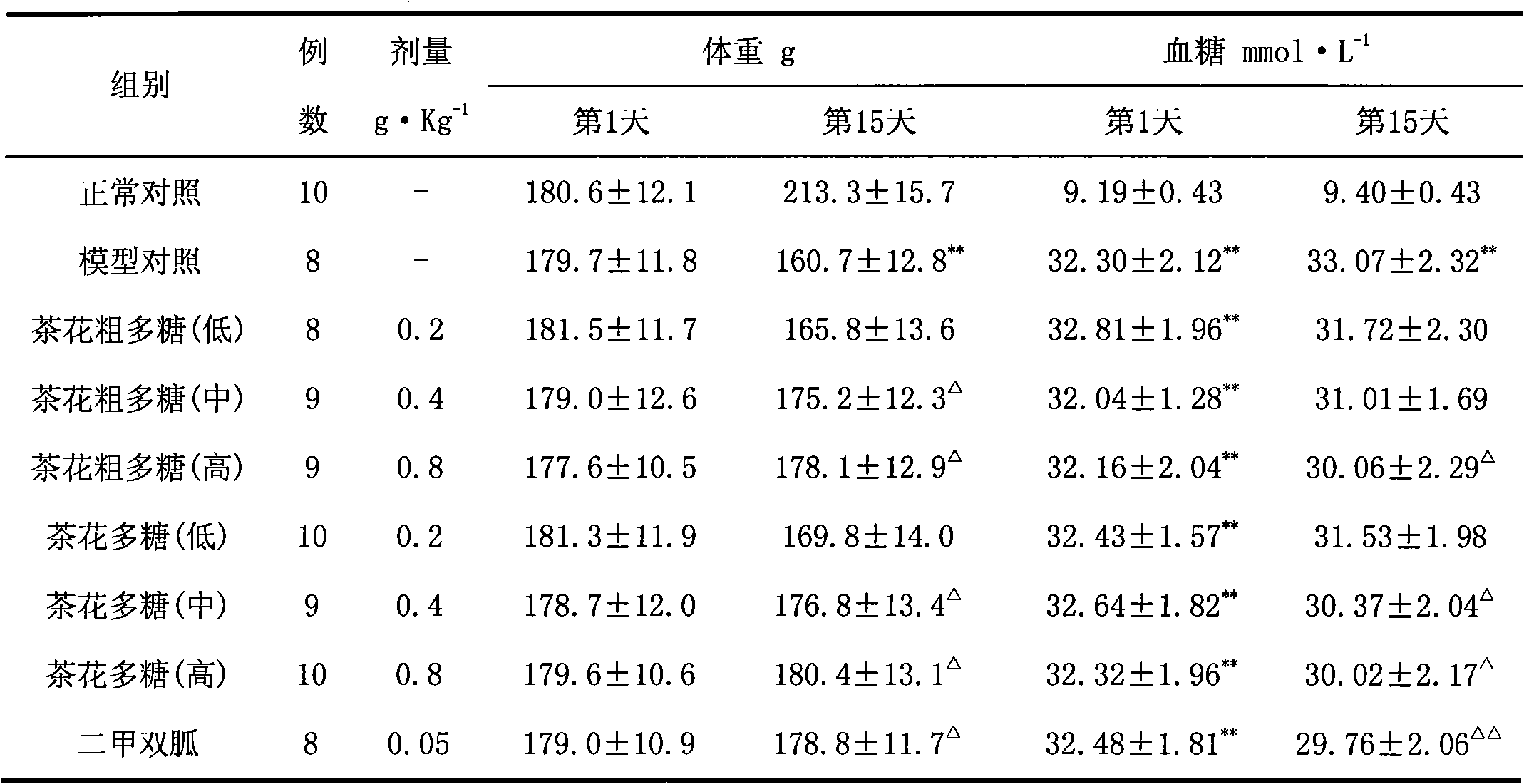

Examples

Embodiment 1

[0026] 10Kg of dried camellia was fed, crushed through a 16-mesh sieve, added 80L of water, stirred, extracted at room temperature for 30 minutes, and centrifuged at 4500 rpm to separate the solid from the liquid and collect the extract. Add 60L of water to the solid precipitated camellia, stir and extract at room temperature for 30 minutes, centrifuge at 4500 rpm to separate the solid and liquid, combine the extract with the first extract, and discard the solid precipitated camellia.

[0027] The combined extracts were concentrated under reduced pressure at 75 degrees Celsius to a density greater than 1.2Kg / L, and after cooling, 4 times the volume of ethanol was added for precipitation for 12 hours. The supernatant was recovered with ethanol, and the precipitate was dried under reduced pressure and vacuum at 75°C. Camellia crude polysaccharide 1.68Kg was obtained.

Embodiment 2

[0029] 10Kg of dried camellia was fed, crushed through a 16-mesh sieve, added with 80L of water, stirred, extracted with a microwave at 600w for 10 minutes, filtered with a plate and frame, and the extract was collected. Add 60L of water to the solid camellia, extract with 600w microwave for 10 minutes, filter the plate and frame to separate the solid and liquid, combine the extract with the first extract, and discard the solid precipitated camellia.

[0030] The combined extracts were concentrated under reduced pressure at 75 degrees Celsius to a density greater than 1.1Kg / L, and after cooling, 4 times the volume of ethanol was added to precipitate for 12 hours. The supernatant was recovered with ethanol and freeze-dried in vacuum. Camellia crude polysaccharide 211g was obtained.

Embodiment 3

[0032] The crude polysaccharide from camellia obtained in Example 1 was dissolved in water, and the ion exchange resin RJA (purchased from Shanghai Mosu Scientific Equipment Co., Ltd.) column was applied at a flow rate of 3 times the column volume per hour, and the tea polysaccharide was eluted after loading the sample, with a yield of 82 %, the decolorization effect is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com