Double-helix coal slime feeder

A feeder and double-screw technology, applied in the field of double-screw slime feeder, can solve the problems of sticking and blocking of the screw feeder, poor combustion effect, and failure of the multi-functional slime feeder to be broken and broken up. , to achieve the effect of expanding the scope of application and improving the combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

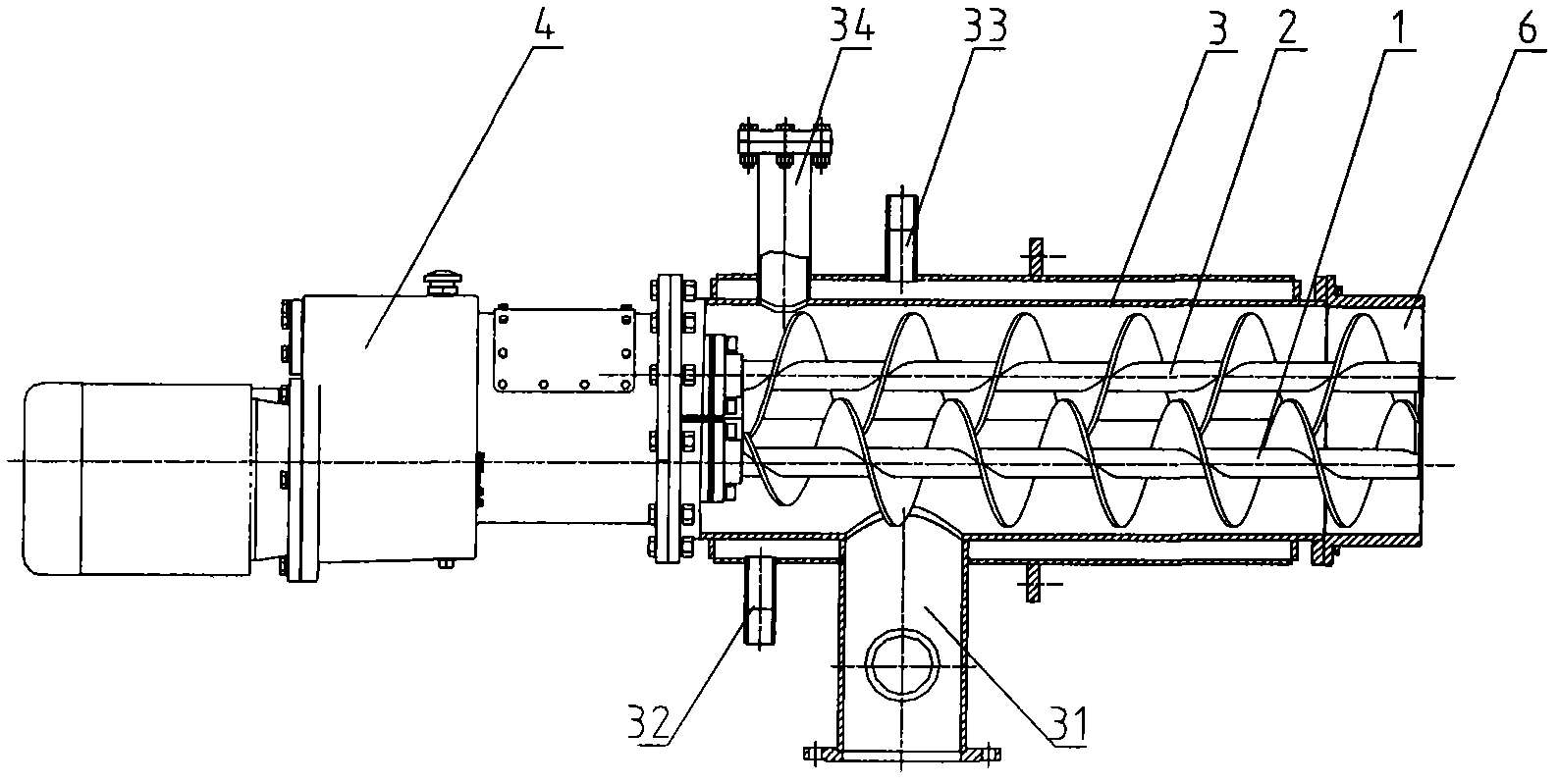

[0039] figure 1 It is the structural representation of the double-screw boiler coal slime feeder of embodiment 1. The slime feeder for the double-screw boiler of this embodiment mainly includes: a slime feeding barrel 3, a first slime feeding screw 1, a second slime feeding screw 2, a feeding screw driving mechanism 4 and a discharge port 6. One end of the coal slime feeding barrel 3 is a feed end, and is connected with the feeding screw drive mechanism 4 , and the other end is a discharge end, and is connected with the discharge port 6 . The coal slime feeding barrel 3 is a double-layer structure, and a cooling water jacket is formed between the inner and outer layers. The water jacket is provided with a water inlet 32 and a water outlet 33, both of which communicate with the inside of the water jacket. A feed inlet 31 and a ventilation pipe 34 are arranged near the feed end, and the feed inlet 31 and the ventilation pipe 34 are all communicated with the inner chamber of ...

Embodiment 2

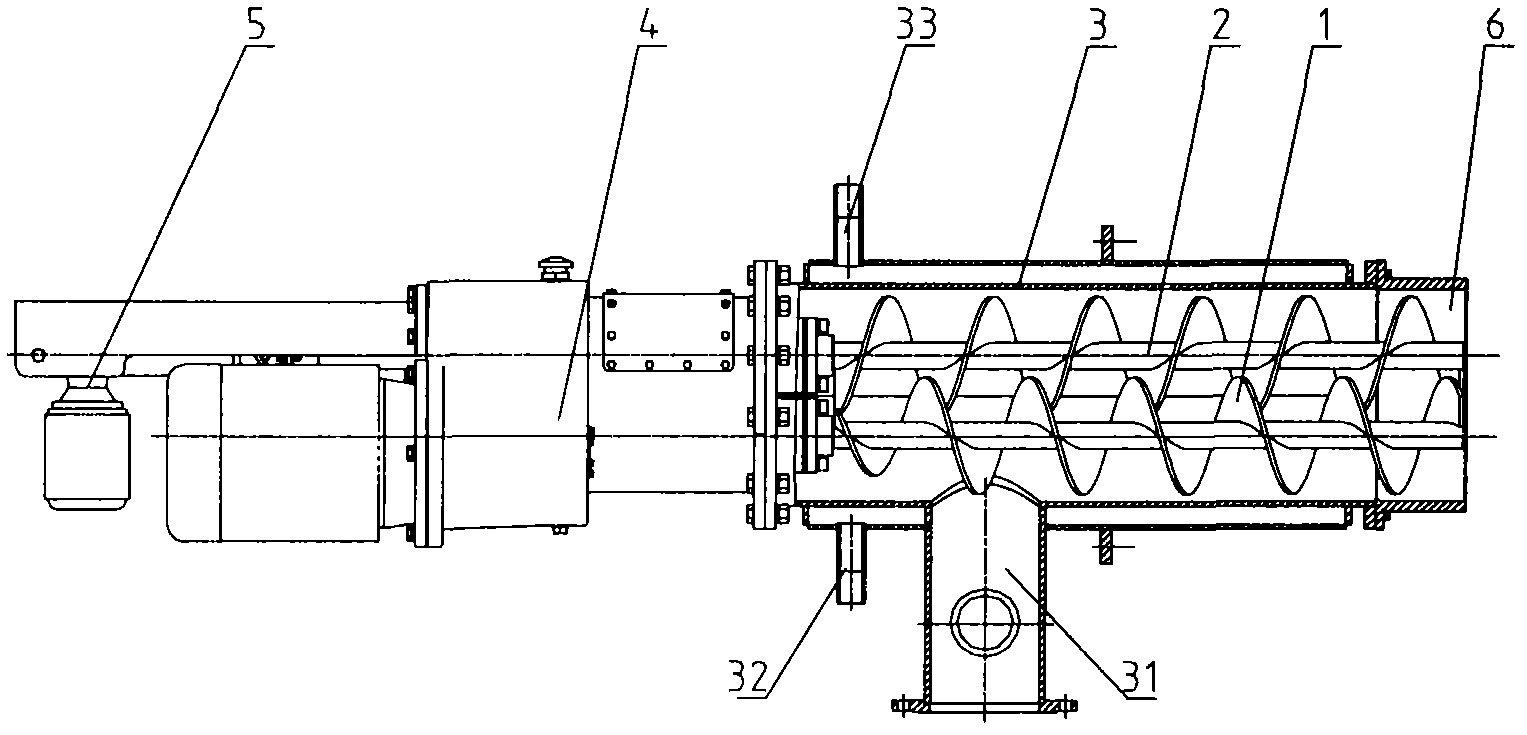

[0044] figure 2 It is the structural representation of the double-screw boiler coal slime feeder of embodiment 2. The double-screw boiler slime feeder of this embodiment mainly includes: a coal slime feeding barrel 3, a first slime feeding screw 1, a second slime feeding screw 2, a feeding screw driving mechanism 4, a feeding screw Linear drive mechanism 5 and discharge port 6. One end of the coal slime feeding cylinder 3 is connected with the feeding screw driving mechanism 4 , and the other end is connected with the discharge port 6 . The coal slime feeding cylinder 3 is a double-layer structure, and between the inner and outer layers is a cooling water jacket. The coal slime feeding cylinder 3 is provided with a feed inlet 31, a water inlet 32 and a water outlet 33, and the feed inlet 31 is connected to the feed cylinder. The inner cavity of 3 communicates, and the water inlet 32 and the water outlet 33 communicate with the inner cavity of the cooling water jacket be...

Embodiment 3

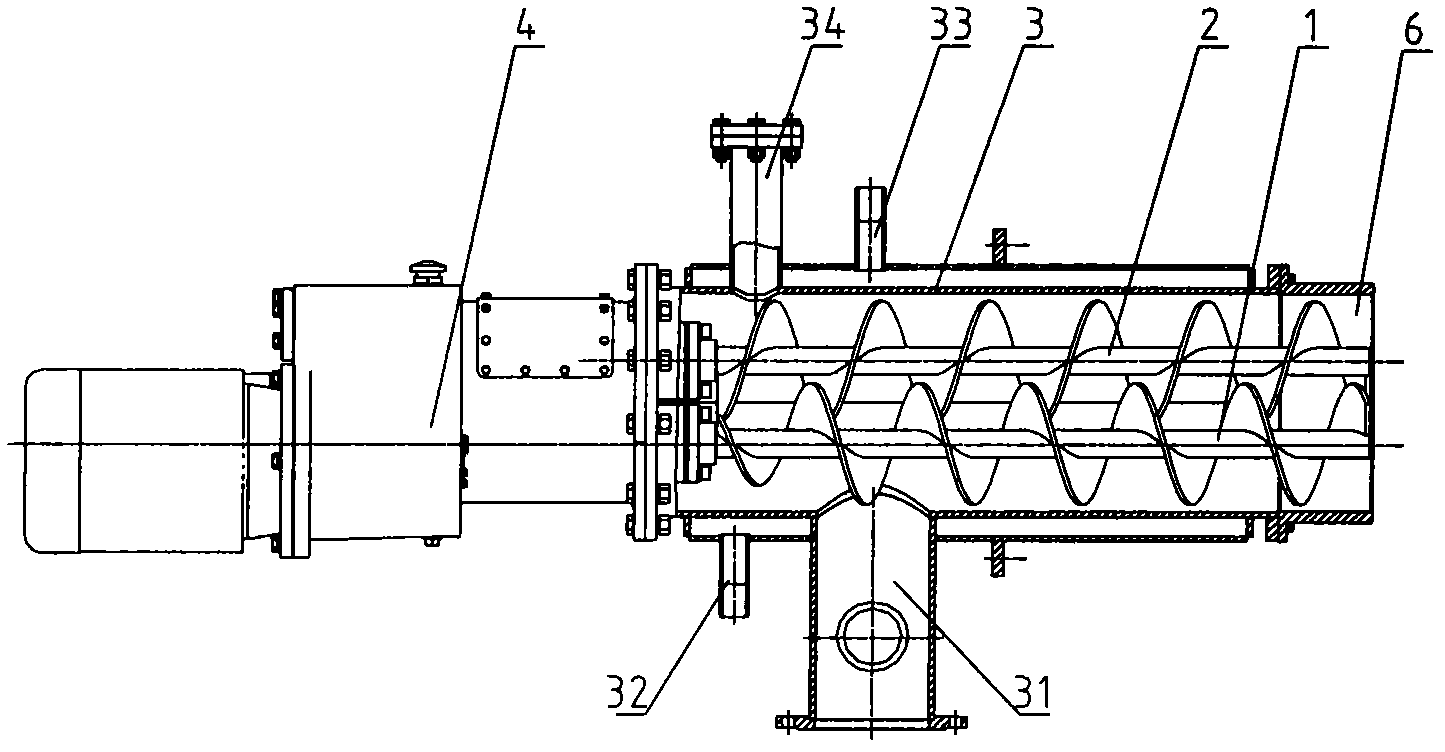

[0050] image 3 It is a structural schematic diagram of the double-screw boiler coal slime feeder of embodiment 3. The slime feeder for a double-screw boiler in this embodiment mainly includes: a slime feeding barrel 3 , a first slime feeding screw 1 , a second slime feeding screw 2 , and a feeding screw driving mechanism 4 . One end of the coal slime feeding cylinder 3 is connected with the feeding screw driving mechanism 4, and the other end is a discharge port 6. The coal slime feeding cylinder 3 is a double-layer structure, and between the inner and outer layers is a cooling water jacket. The coal slime feeding cylinder 3 is provided with a feed inlet 31, a water inlet 32, a water outlet 33 and a ventilation pipe 34. The feed inlet 31 and the ventilation pipe 34 communicate with the inner cavity of the barrel 3 , and the water inlet 32 and the water outlet 33 communicate with the inner and outer walls of the barrel 3 to form a cooling water jacket.

[0051] The feeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com