Intermittent type intelligent thermal transfer multi-head printer

A thermal transfer printing and printer technology, applied in typewriters, printing, etc., can solve the problems of ribbon waste, installation space limitation, long ribbon, etc., to improve the ability to save ribbon, reduce production costs, and enrich printing content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

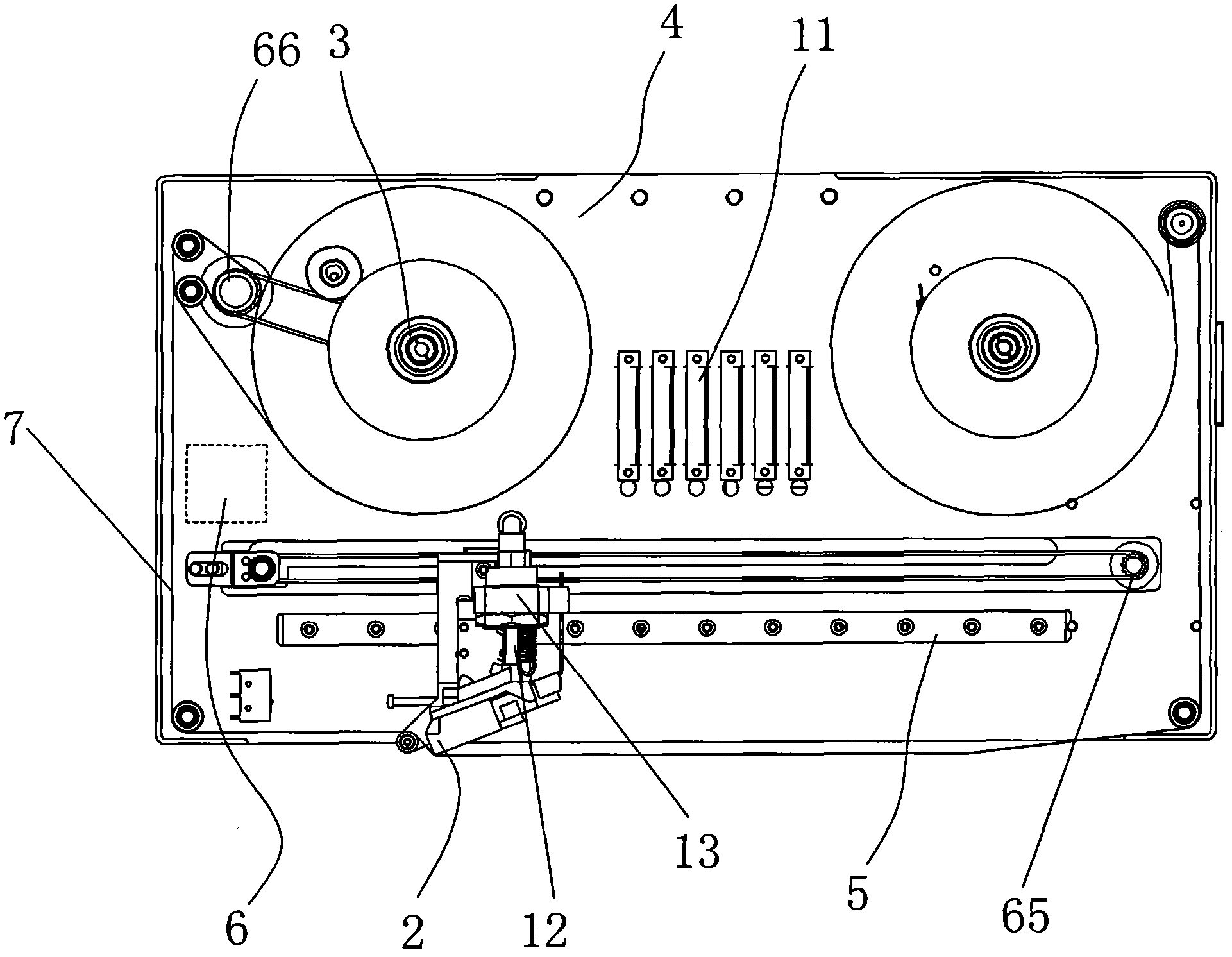

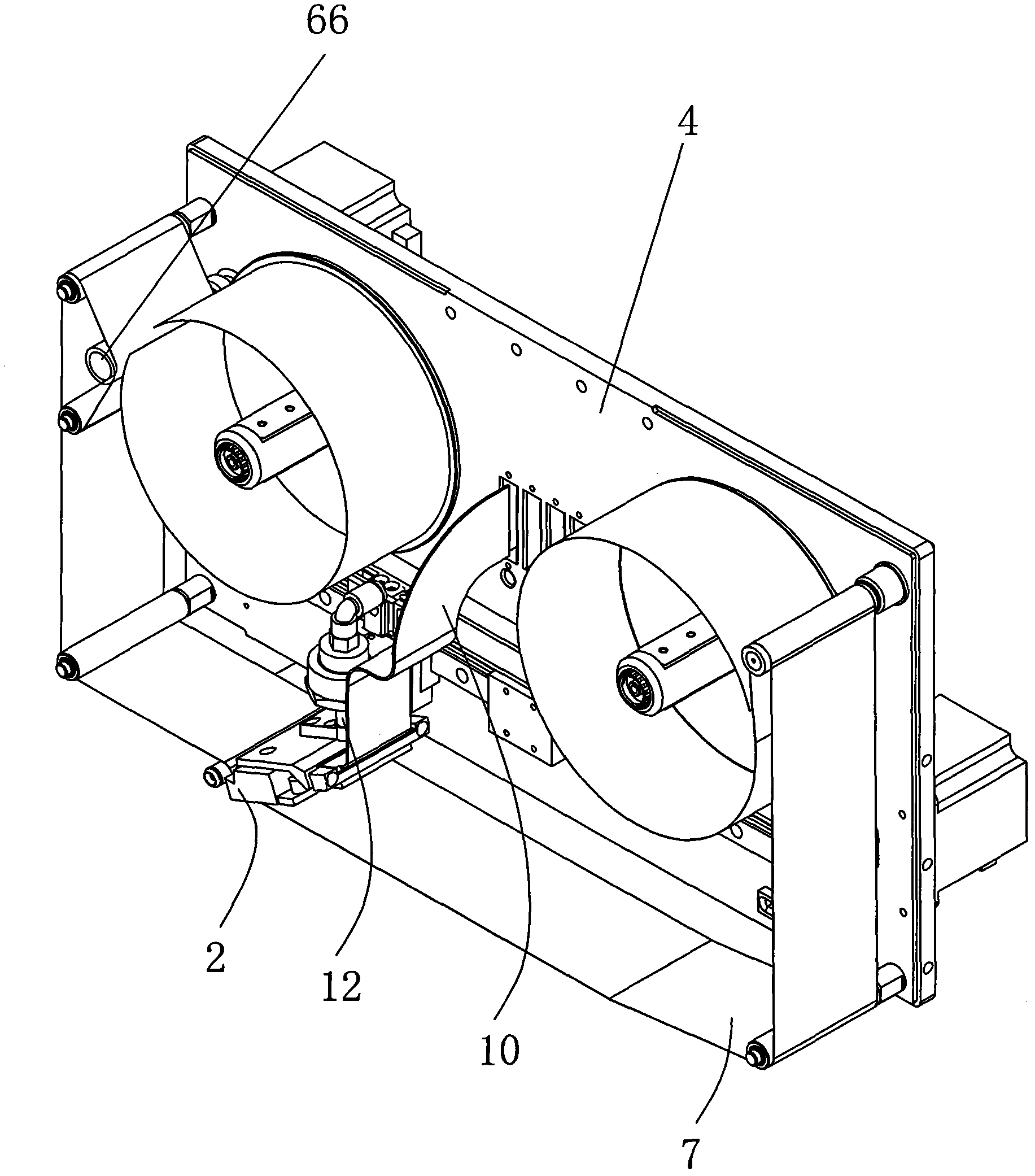

[0022] Reference Figure 1 to Figure 5 , The present invention is implemented as follows:

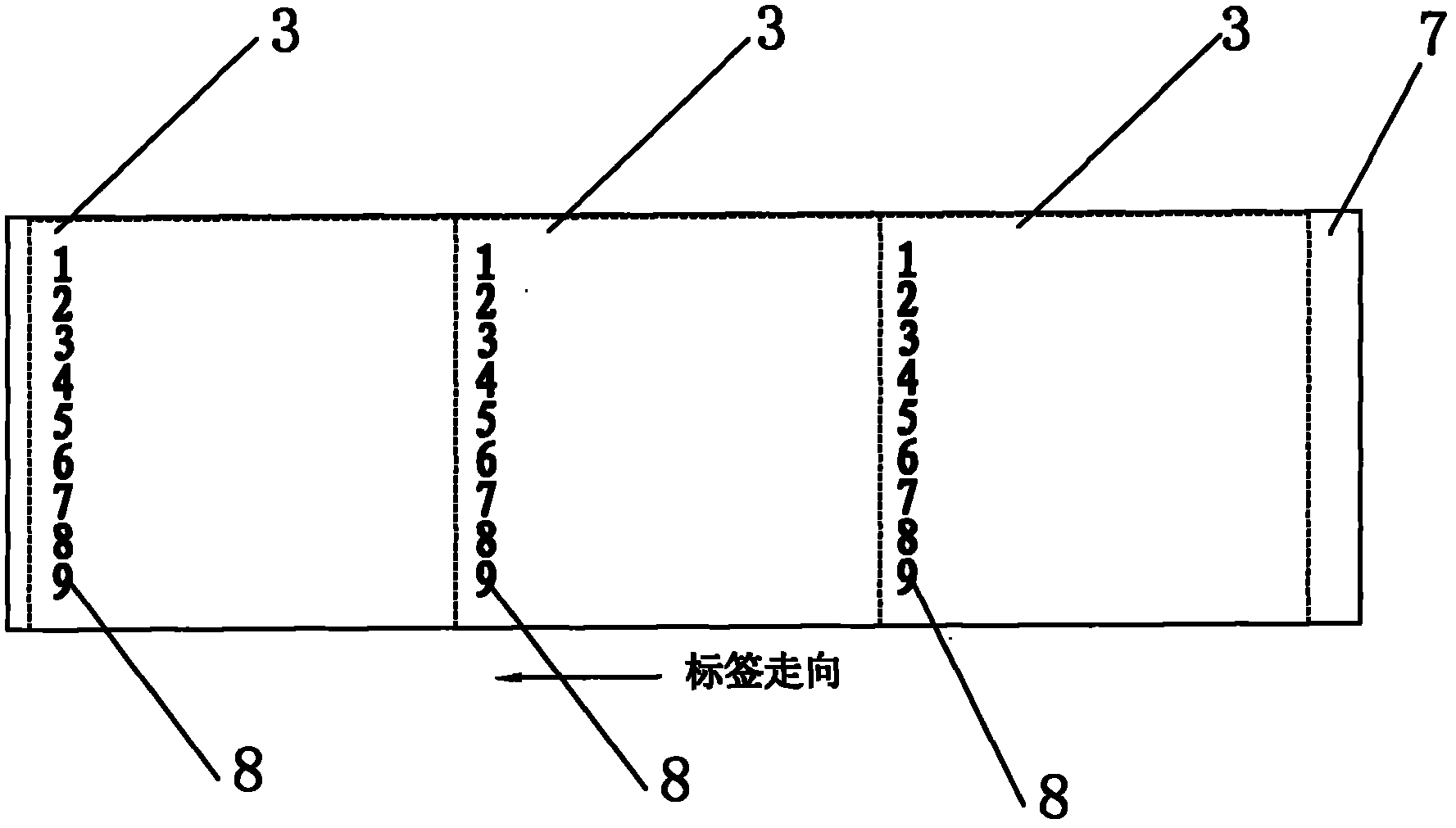

[0023] in figure 1 with figure 2 In, an intermittent intelligent thermal transfer multi-head printer includes a print head clamping device, a print head (2), a print head drive device, a ribbon transmission device (3) and a frame (4), and is characterized in that: The print head (2) and the ribbon transmission device of the print head are controlled by the controller (6). The ribbon cable 10 of the print head passes through the wire hole 11 and is connected to the controller. The controller controls the print head drive motor and the ribbon drive motor. The head (2) is set in the slide rail (5) of the rack (4). It first determines the number of prints that need to be printed in a round trip of the print head, and then determines the distance between each print. Due to the content of the print file and the The size is set by the controller, so when printing, the controller (6) divides the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com