Heat setting device of pillow core

A heat-setting and pillow core technology, which is applied to household components, household appliances, other household appliances, etc., can solve the problem that the elasticity, comfort and product quality of the pillow core cannot be substantially improved, and the hot-melt temperature cannot be reached. Problems such as heat setting cannot be realized, and the effect of speeding up the time of heat setting, improving production efficiency and uniform elasticity can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in further detail by the following examples.

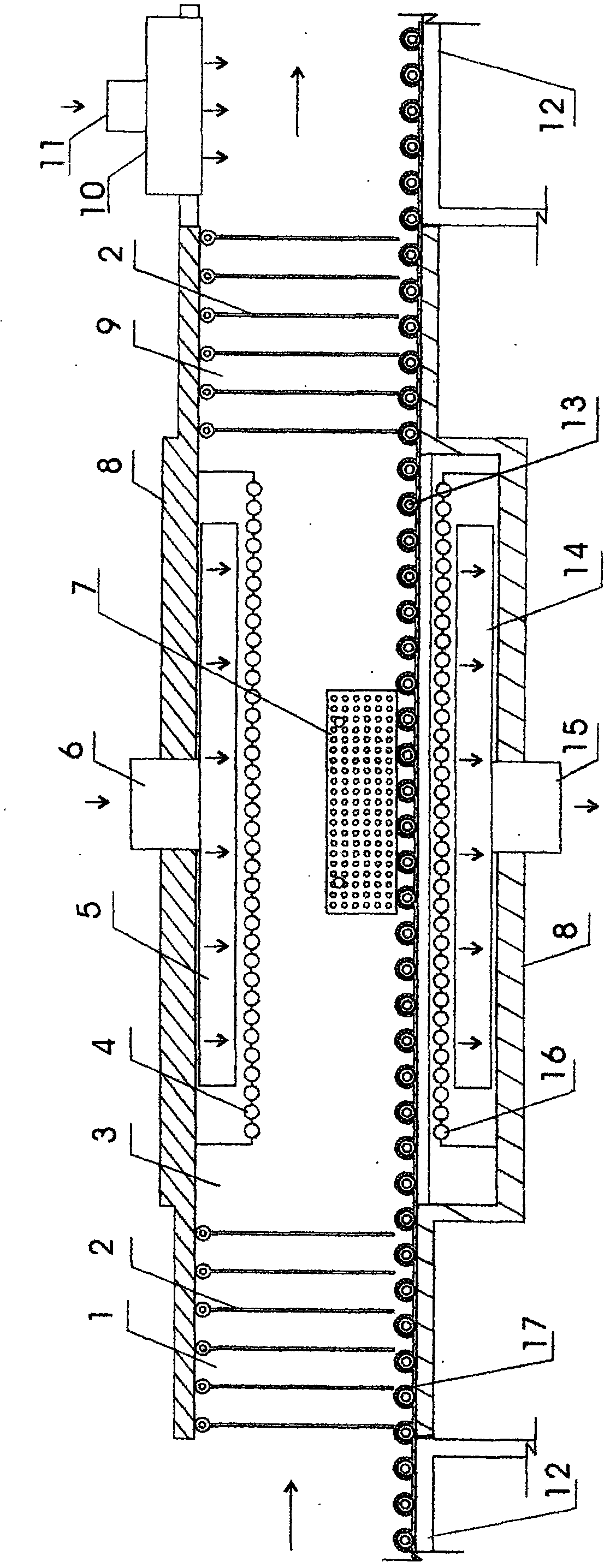

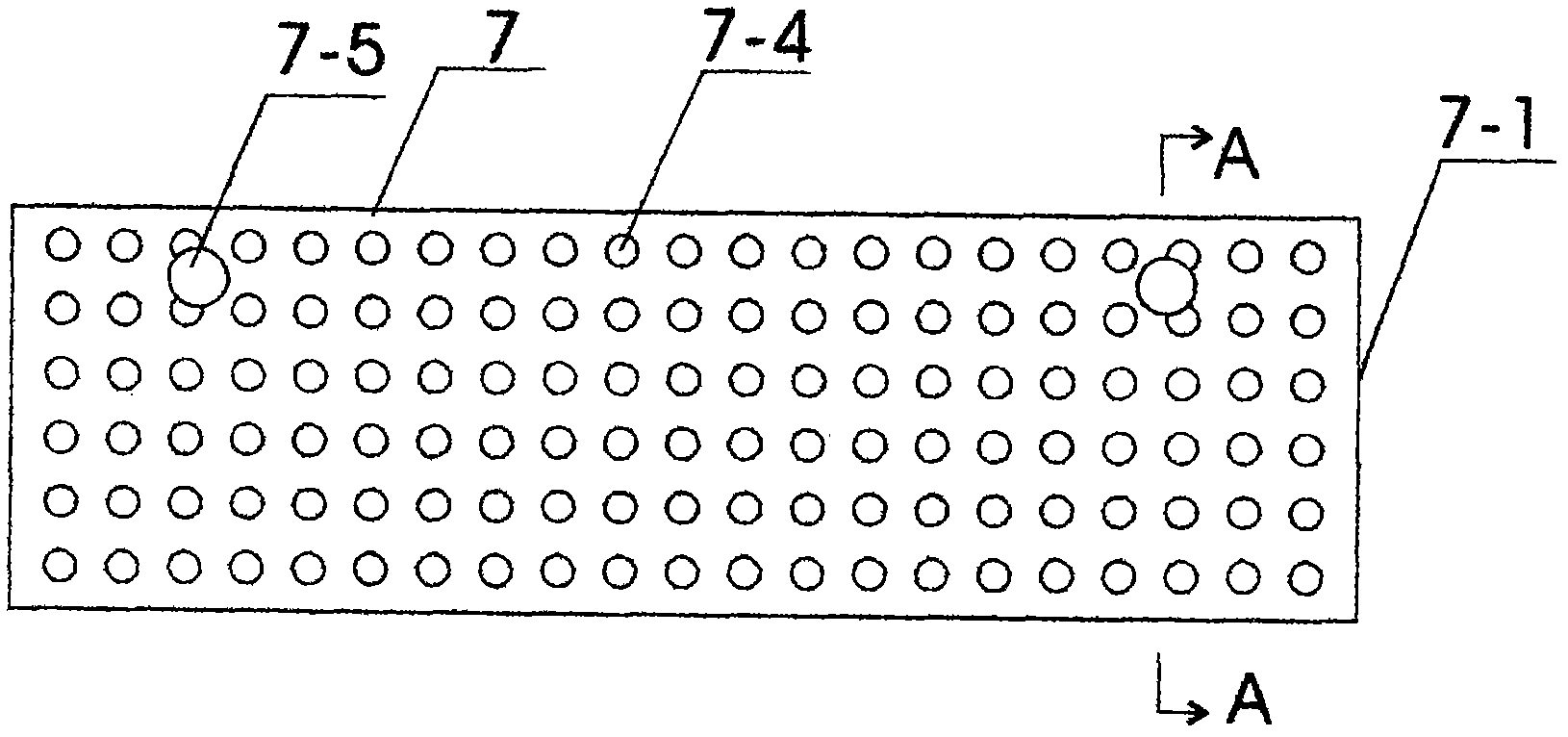

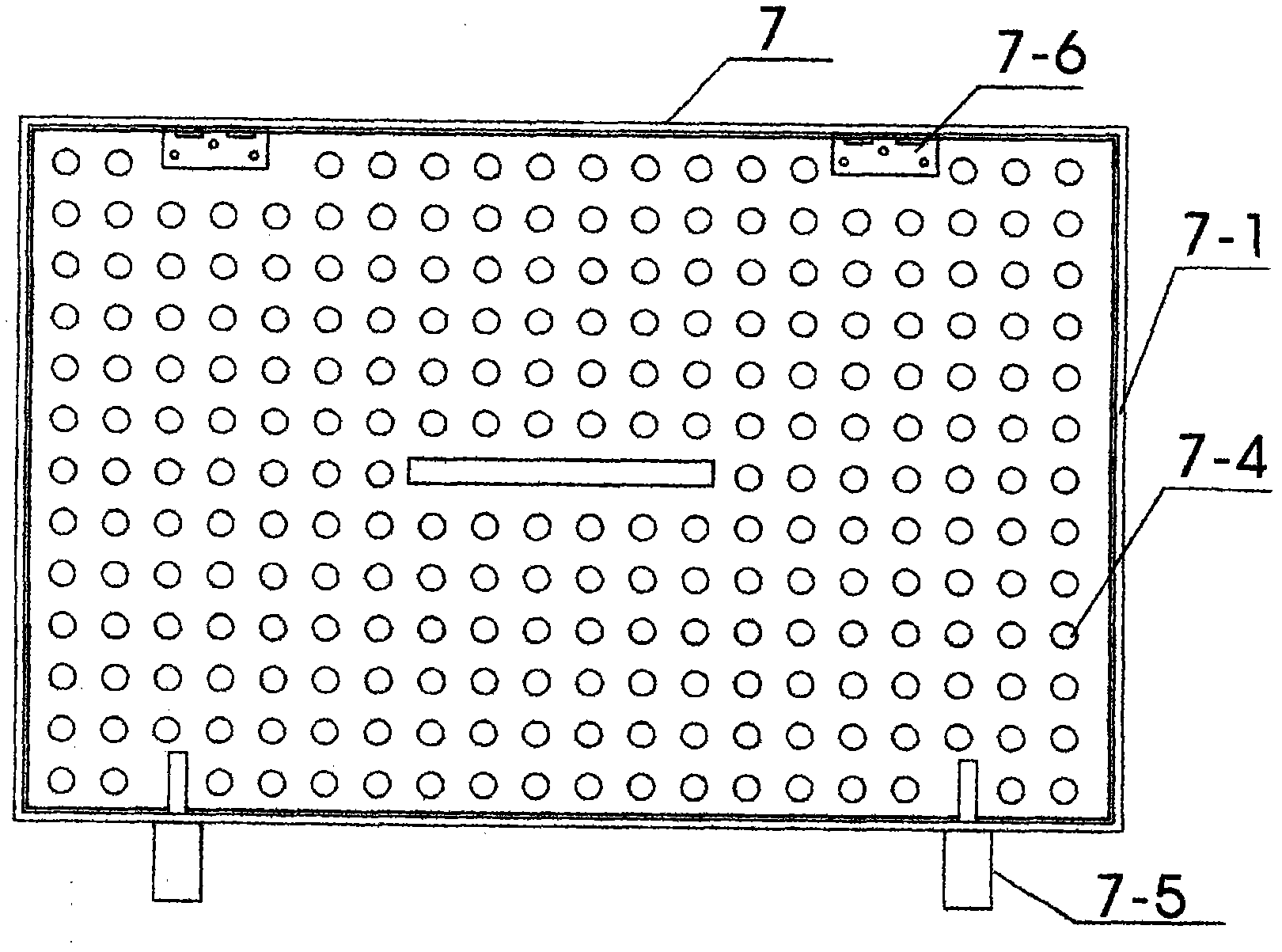

[0023] see Figure 1-Figure 4 As shown, a pillow core heat setting device is composed of a heating furnace, a roller conveyor belt, a hot air circulation system, a heat setting mold 7 and a cold air cooling device. The heating furnace is composed of a left furnace chamber 1, a middle furnace chamber 3 and a right furnace chamber 9. A row of horizontal and equidistant far-infrared heating tubes 4 are arranged on the middle furnace chamber 3 top, and a row of horizontal and equidistant far-infrared heating tubes 16 are arranged on the middle furnace chamber 3 bottom. There is a roller conveyor belt on the top, and the roller conveyor belt extends outward along the left and right furnaces 1 and 9 to form an oval transportation line. This oval transportation line can be composed of several groups of roller conveyor belts . An air inlet chamber 5 is arranged between the upper row of far-infr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com