Automatic inner hole chamfering machine

A technology of chamfering machine and inner hole, which is applied in the direction of automatic control device, boring/drilling, drilling/drilling equipment, etc. It can solve the problems of affecting product quality, easy to touch the workpiece, and affecting the service life of the product. Achieve the effect of realizing automatic work, ensuring accuracy and ensuring precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

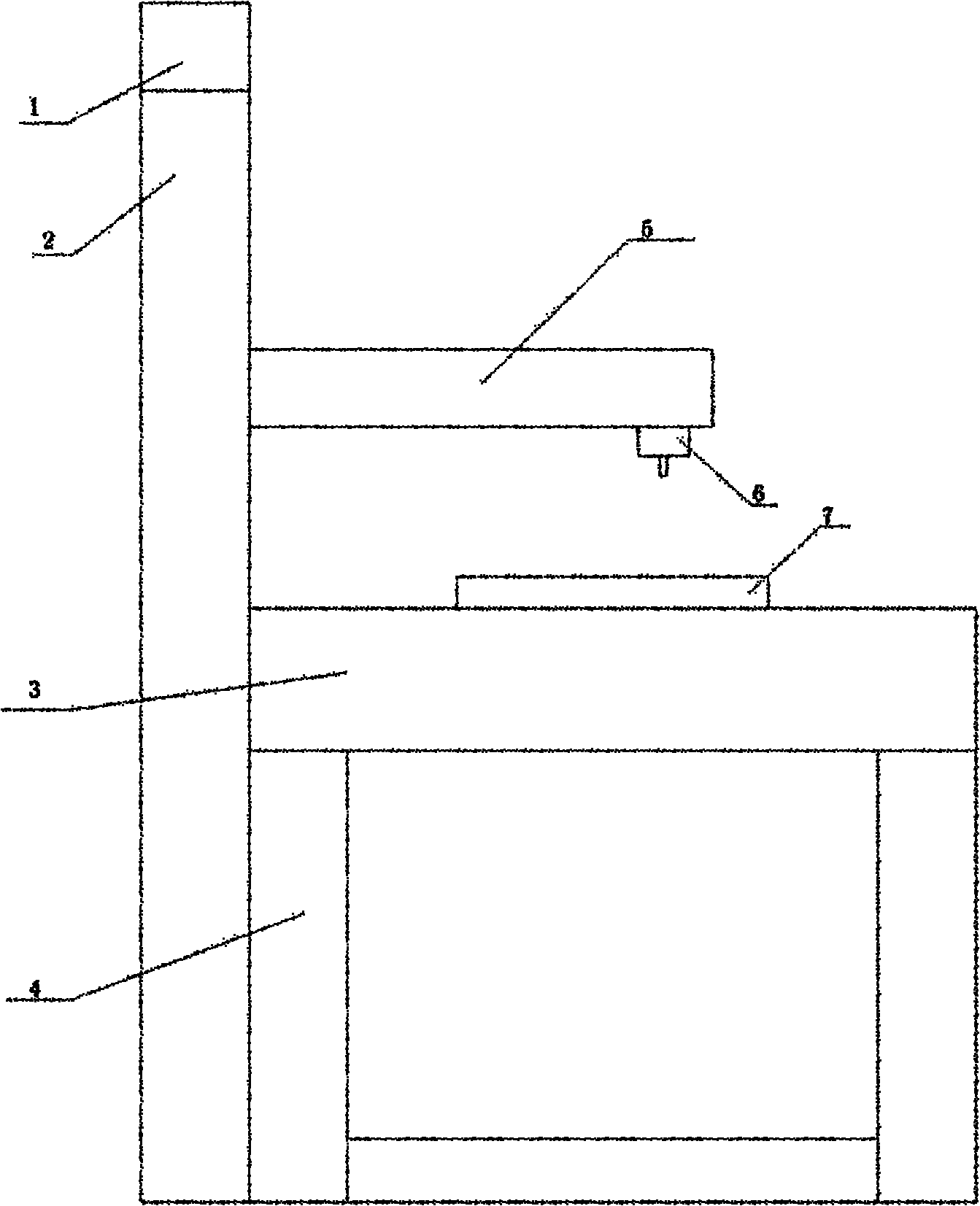

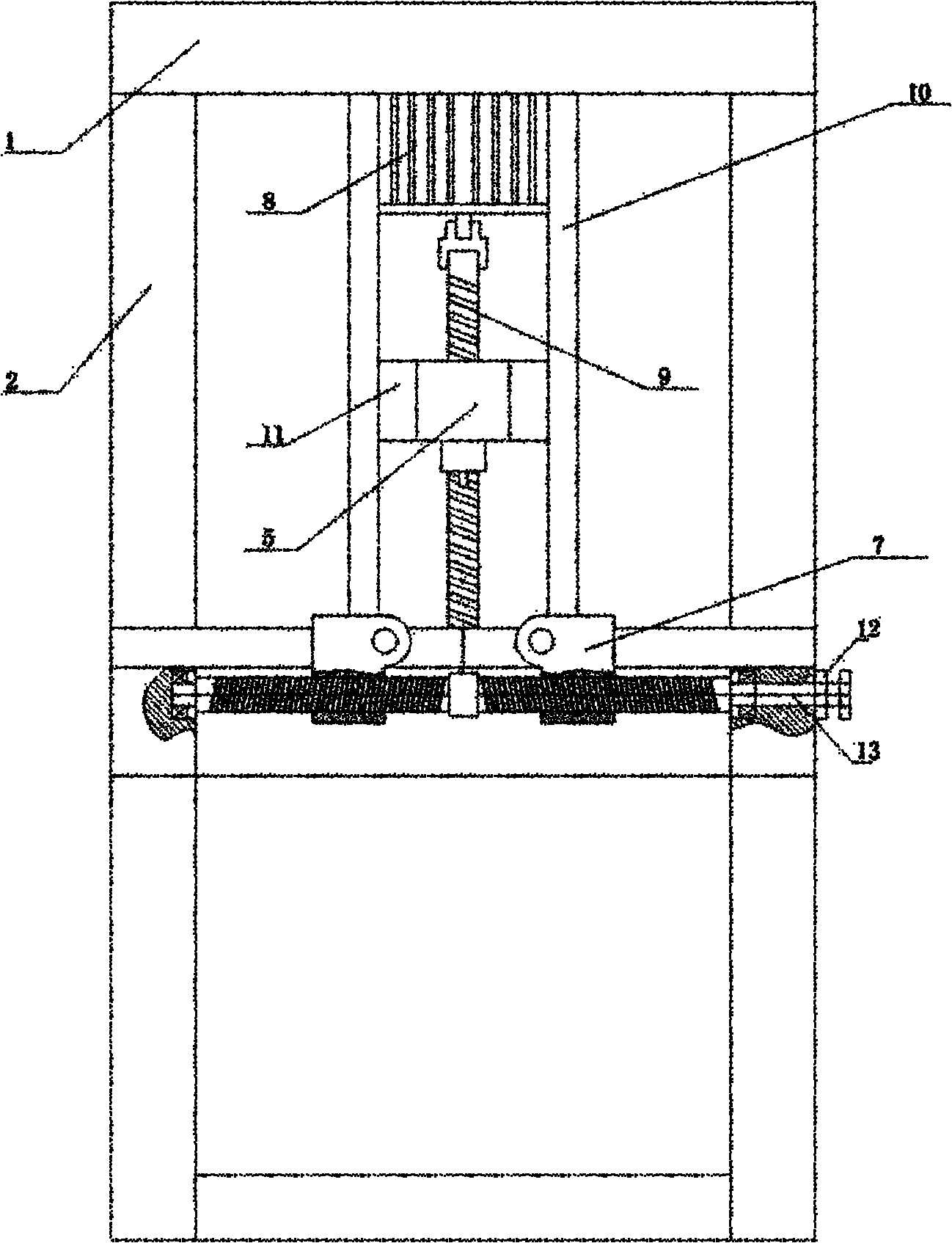

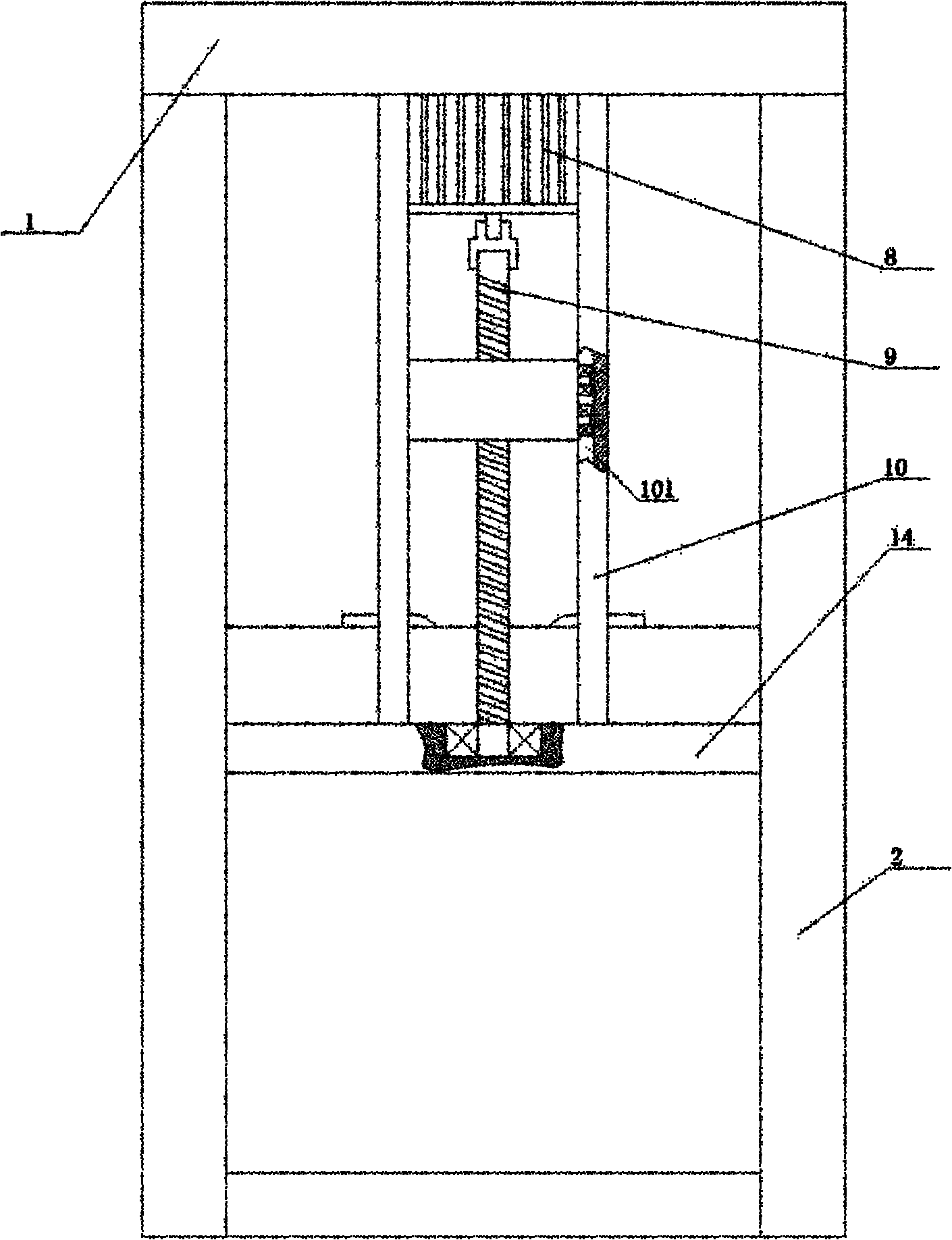

[0024] The present invention is further described below with reference to accompanying drawing,

[0025] Such as Figure 1 to Figure 5 The shown automatic inner hole chamfering machine includes a base 4, the upper part of the base 4 is provided with a workbench 3, and the two sides on the left side of the base 4 are fixedly connected with pillars 2, and the tops of the two pillars 2 are connected by an upper beam 1. A lower crossbeam 14 is also provided at the middle and lower part between the two pillars 2, and the upper surface of the workbench 3 is higher than the lower crossbeam 14, and a height adjustment mechanism is arranged between the upper crossbeam 1 and the lower crossbeam 14. Be provided with a crossbeam 5, be provided with a cutting device on the crossbeam 5, described cutting device is an air drill 6, the height adjustment mechanism that we set here is mainly used for adjusting the height of the crossbeam 5, is convenient for the positioning of the workpiece, mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com