Foaming tool with safety control mechanism

A technology of safety control and tools, which is applied in the direction of building construction, fastening/covering of joints, and devices for coating liquid on the surface, etc. It can solve problems such as inaccurate adjustment, too light adjustment, and adjustment screw rotation, etc., to achieve The adjustment movement is obvious, the phenomenon of falling off is prevented, and the adjustment is convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

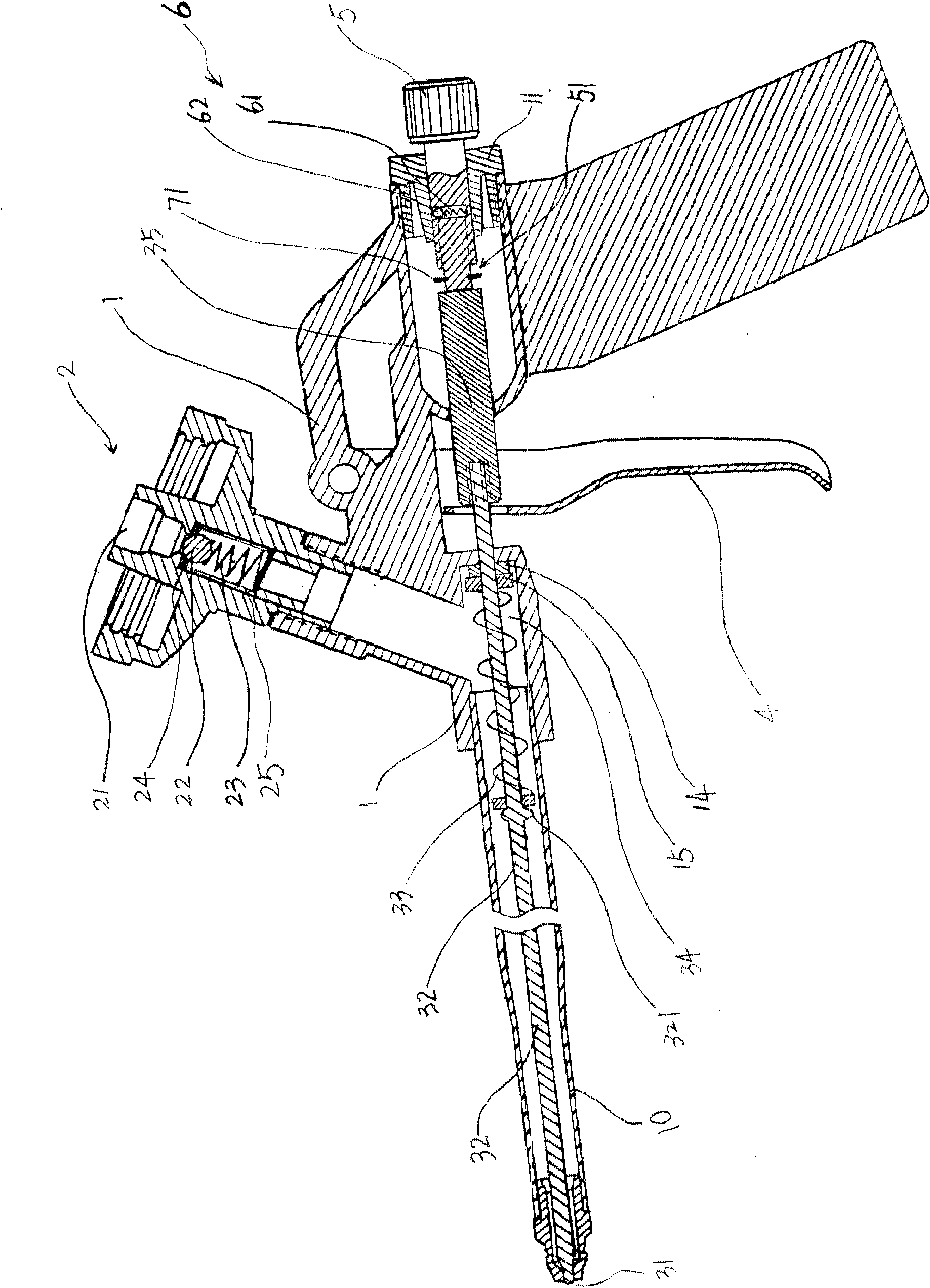

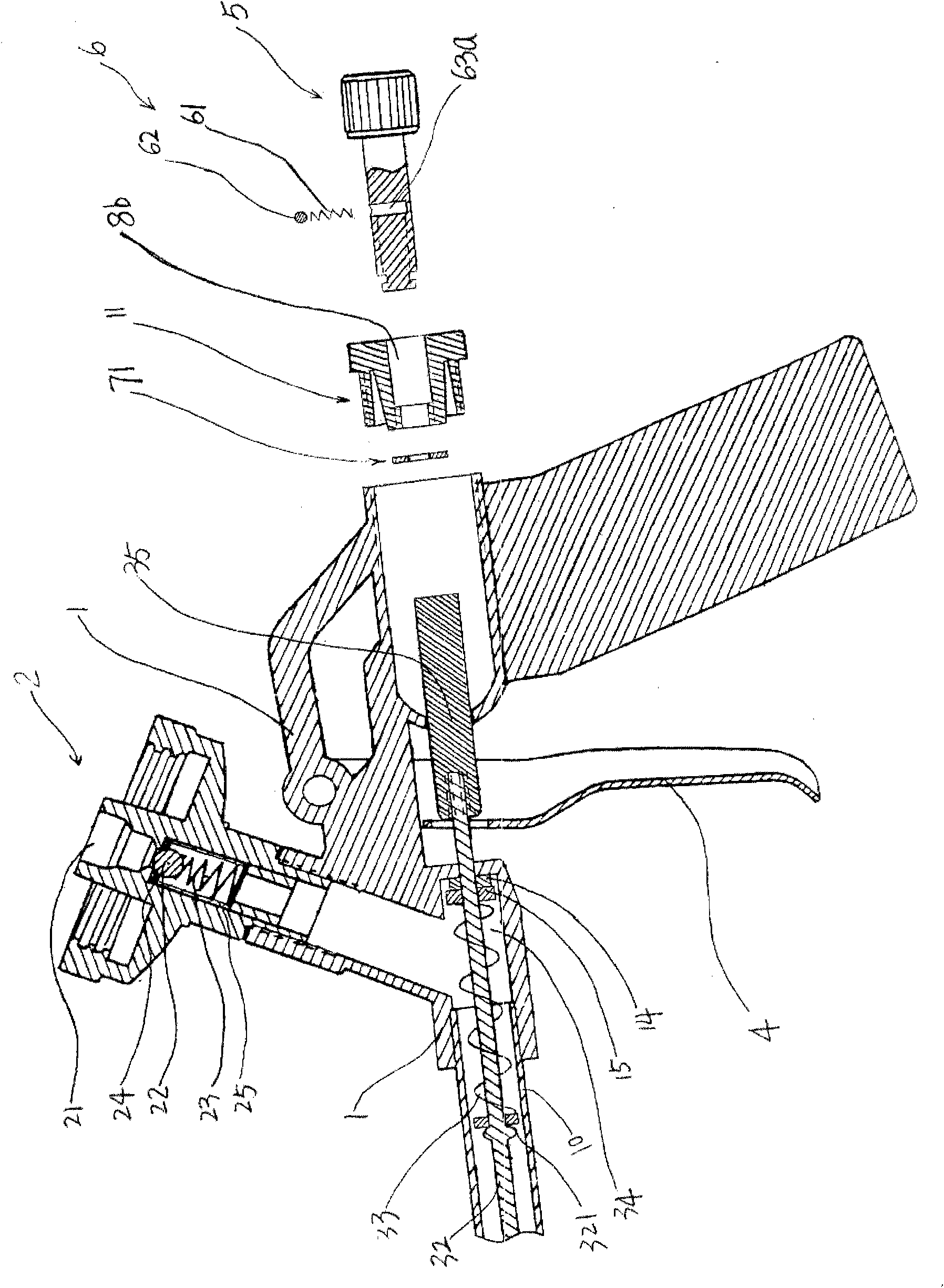

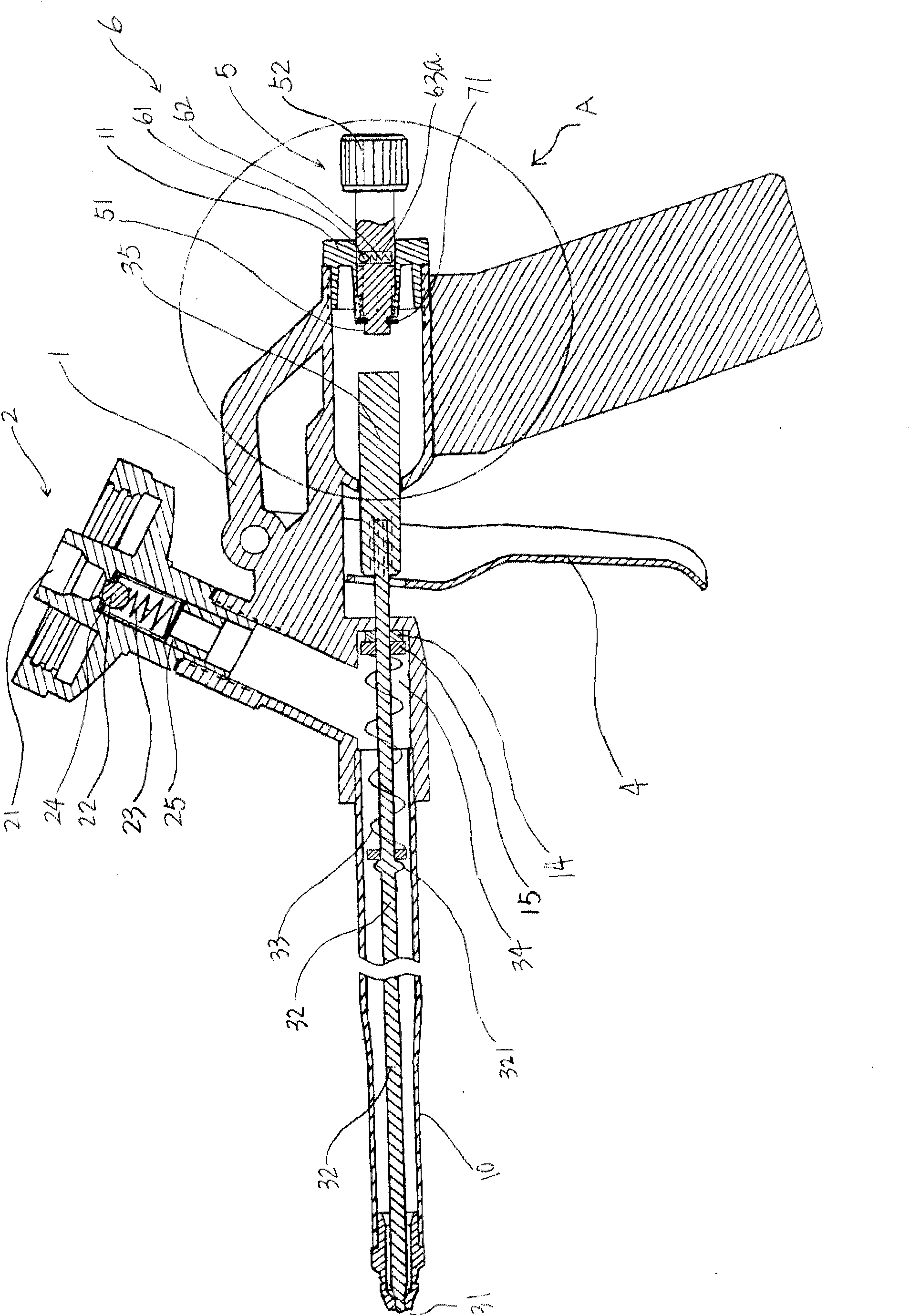

[0102] see Image 6 , a maximum flow control mechanism for controlling the maximum flow is provided on the adjustment member 5, further, the maximum flow control mechanism is a mechanism for controlling the maximum movement distance of the adjustment member 5 and / or the spool 32, and further, the maximum The flow control mechanism is jumper 71 (referring to figure 2 and Figure 4 ) or a threaded fastener 72 (see Image 6 or Figure 8 or Figure 9 ), the adjustment part is also equipped with a maximum flow control mechanism for controlling the maximum flow, which has a simple structure, low cost, convenient installation, high strength, and is safer and more reliable. Quality, to prevent leakage, prevent the safety control mechanism from falling off, and prevent the adjustment parts from falling off.

[0103] In addition, the maximum flow control mechanism is set at the inner end 51 of the adjustment member 5, the inner end of the adjustment member 5 refers to the end of t...

Embodiment 3

[0106] see Figure 7 , this embodiment is similar to Embodiment 1, and the difference is that: the adjustment member 5 is arranged obliquely along the axial direction of the valve core 32, the structure is simple and reasonable, the cost is low, the installation is convenient, the style is beautiful, and the adjustment is convenient and smooth; in addition , The fixed sleeve 11 and the gun body 1 are connected and fixed by the fixing screws 54, 54', the structure is simple and reasonable, and the installation is convenient.

Embodiment 4

[0108] see Figure 8 and Figure 9 , the safety control mechanism is arranged between the adjustment member 5 and the gun body 1, further, a first adjustment through hole 8a is provided on the gun body 1, and the adjustment member 5 and the gun body 1 pass through the The first adjustment through hole 8a is threaded and can produce relative displacement with the gun body 1, so that the adjustment member 5 can be telescopically moved, so that the user can feel the adjustment member 5 move to the desired position for controlling the flow rate , the safety control mechanism 6 is arranged on the adjustment member 5, the first groove 63a is provided on the adjustment member 5, the ball 61 and the spring 62 are arranged in the first groove 63a, the safety One end (ball 61) of the control mechanism 6 acts on the inner wall of the first adjustment through hole 8a, so that the movement is hindered between the two contact surfaces, and all the parts in contact with the inner wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com