Multi-layered composite blanket and production process

A multi-layer composite, production process technology, applied in the direction of layered products, blankets, sleeping blankets, etc., can solve the problems of glue residue, adverse factors of human health, limited application scope, etc., to simplify the processing and production process, suitable for large-scale Production and application of a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In conjunction with the accompanying drawings, the present invention will be described in further detail.

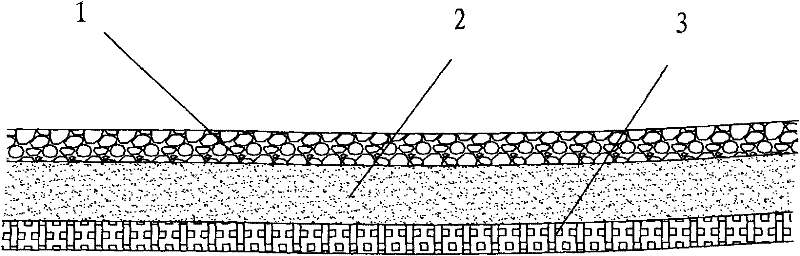

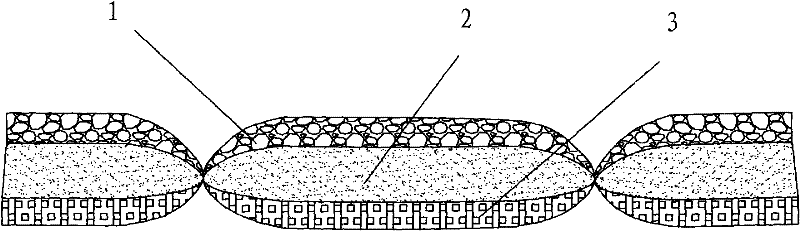

[0025] Such as figure 1 , figure 2 As shown, the multi-layer composite blanket includes an upper layer 1, a middle layer 2, and a lower layer 3.

[0026] The upper layer 1 and the lower layer 3 are fabric layers that are in direct contact with the human body. In order to enhance the texture of skin touch, the upper layer 1 is made of polyester super soft short plush, and the lower layer 3 is made of polyester velvet.

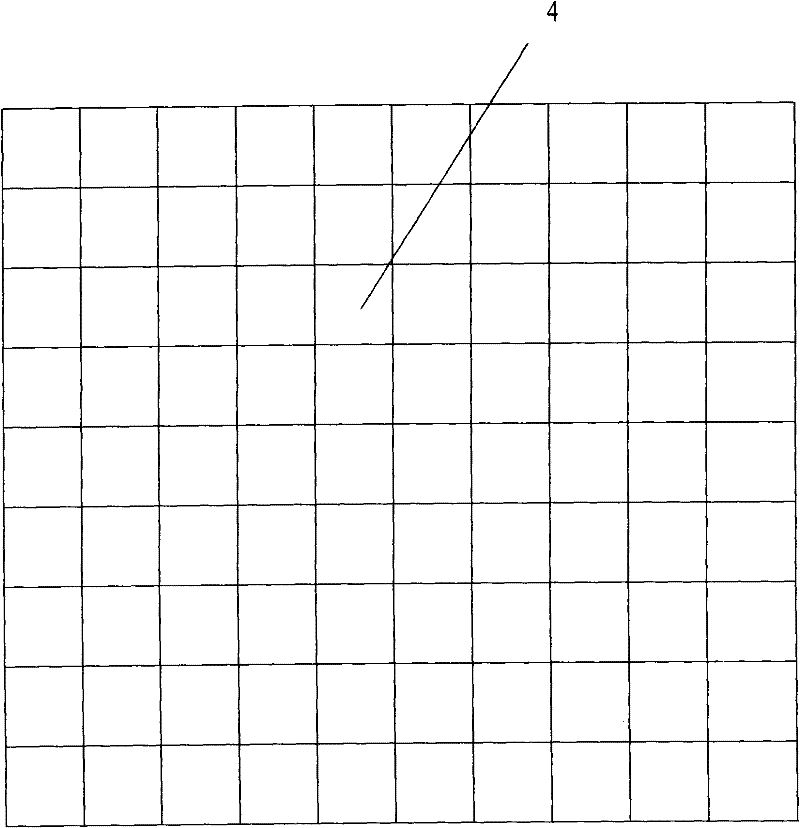

[0027] The middle layer 2 is a filling layer, which is light in texture and has good polyester non-glue cotton of warming effect. After the three layers are stacked in sequence, they are sent to the quilting embroidery machine for quilting embroidery, such as image 3 In the shown embodiment, quilting forms several grids 4, the sewing is firm, and the flower shape is simple.

[0028] There is patch reinforcement 5 around the entire perimeter o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com