Tensioning mechanism for seedling clamping convey chain

A tensioning mechanism and conveying chain technology, which is applied to harvesters, excavating harvesters, agricultural machinery and implements, etc., can solve the problems of large tensioning mechanism, small tensioning force, inconvenient installation, etc., and achieve compact structure , strong tension and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

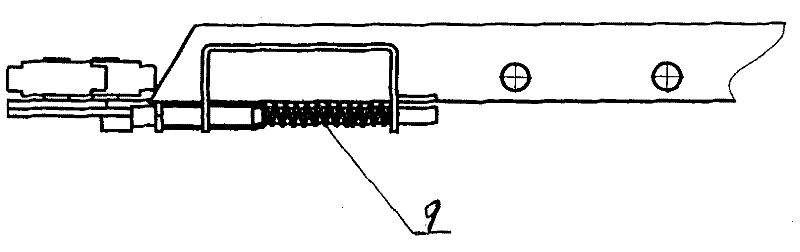

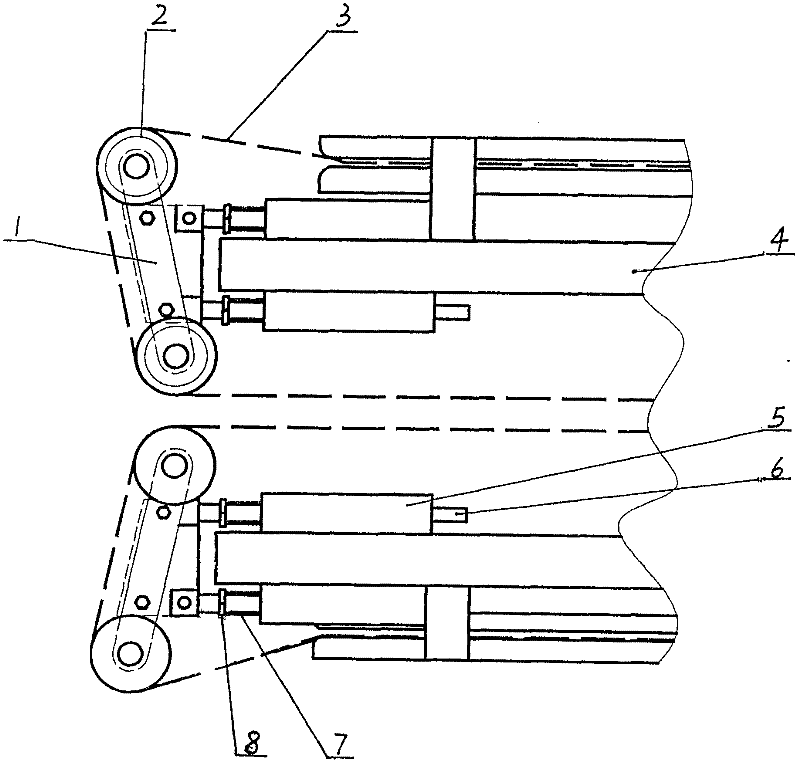

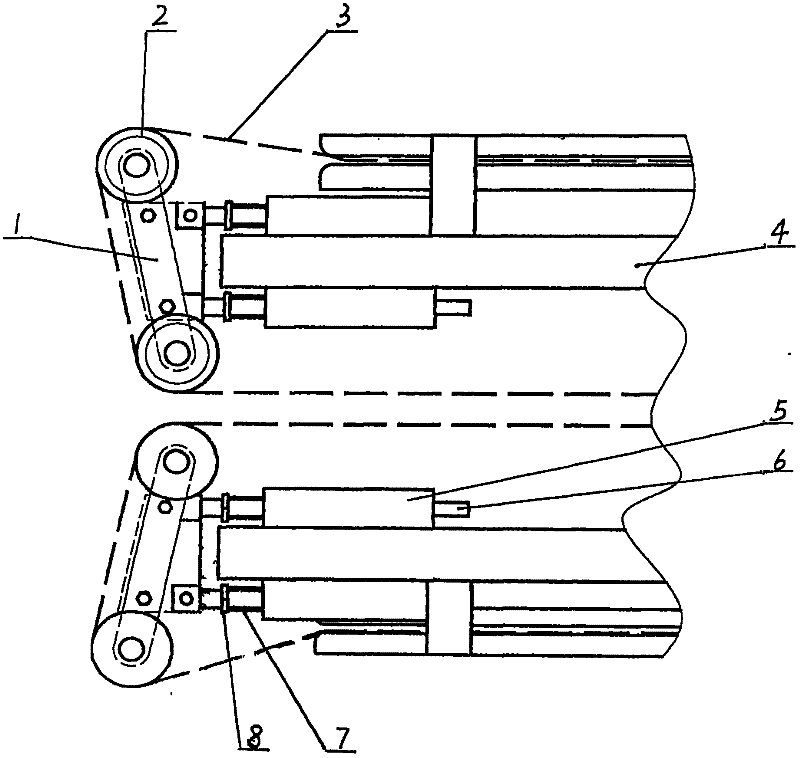

[0010] exist figure 1 , figure 2 Among them, on the movable frame 4 of the peanut combine harvester, the tensioning part of the seedling-clamping conveying chain 3 is installed and installed with two sets of left-right symmetrical tensioning mechanisms separated by a certain distance, and the two sets of tensioning mechanisms respectively tension two side-by-side Seedling clamping conveying chain 3. Each tensioning mechanism is supported by two U-shaped frames 5, two tensioning springs 9, two tensioning shafts 6, two tensioning shaft sleeves 7, two tensioning adjustment nuts 8, and a tensioning wheel Plate 1, two tensioning wheels 2, etc. are sequentially installed on the movable frame 4. The specific structure is: two U-shaped frames 5 are installed and fixed side by side on the movable frame 4 at a certain distance, and the two ends of the U-shaped frame 4 A round hole is opened in the middle part, two round holes are one big and one small, the big round hole fits with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com