Roll-to-roll distance measuring device

A technology of measuring device and roller interval, which is applied in the direction of measuring device, mechanical gap measurement, using optical device, etc., can solve the problems of difficult to grasp the peak value of displacement and the decrease of measurement accuracy, so as to suppress the bite of foreign objects, ensure soundness, The effect of high-precision measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] Hereinafter, preferred embodiments of the present invention will be described.

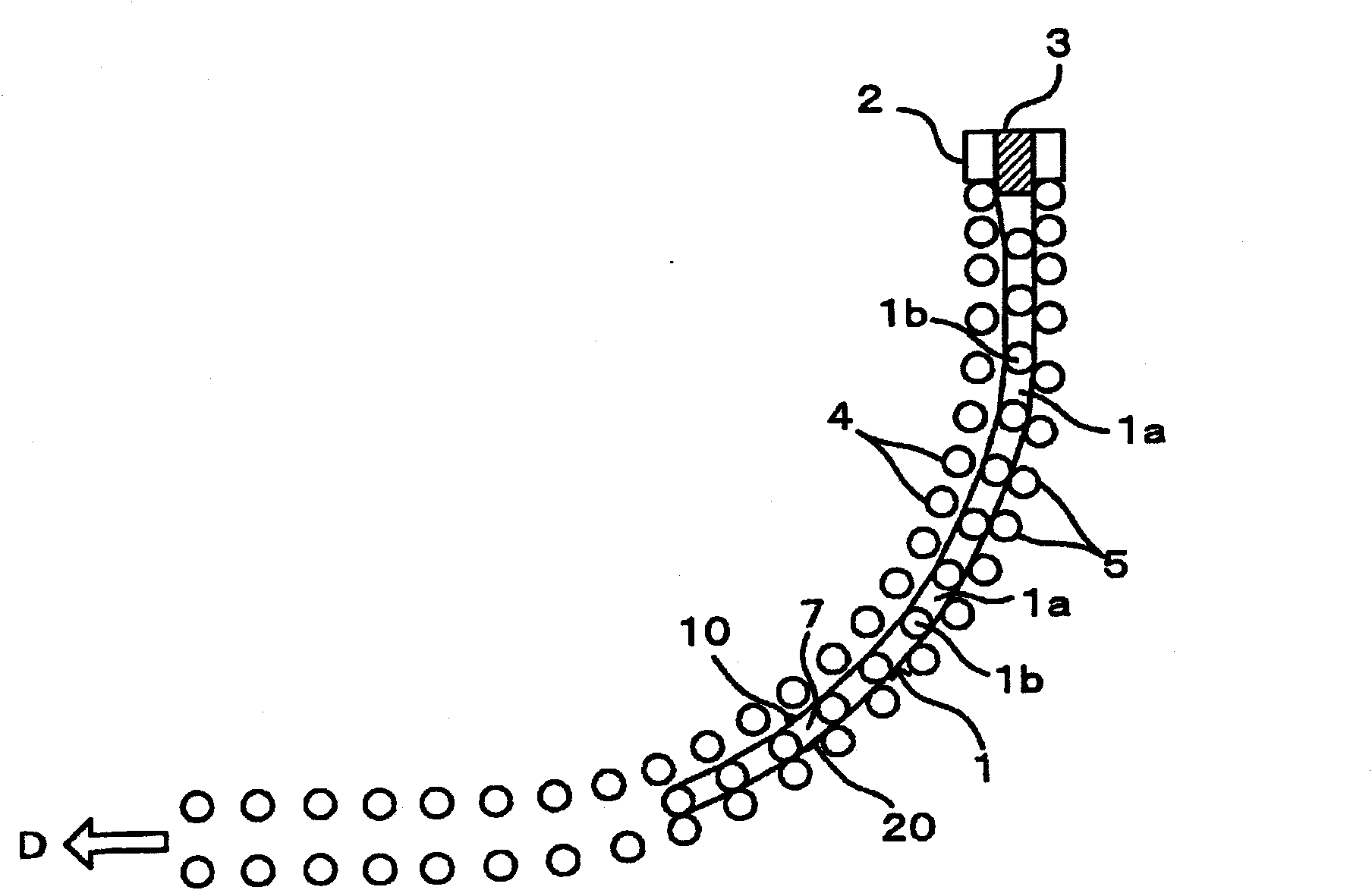

[0086] figure 1 It is a side view schematically showing the dummy bar 1 on which the roll gap measuring device according to this embodiment is mounted. The dummy bar 1 has a plurality of link members 1a and a shaft 1b, and guides molten steel 3 cast from a tundish not shown through a mold 2 so that it passes through a slab passage formed between a plurality of rollers 4 and 5. move within.

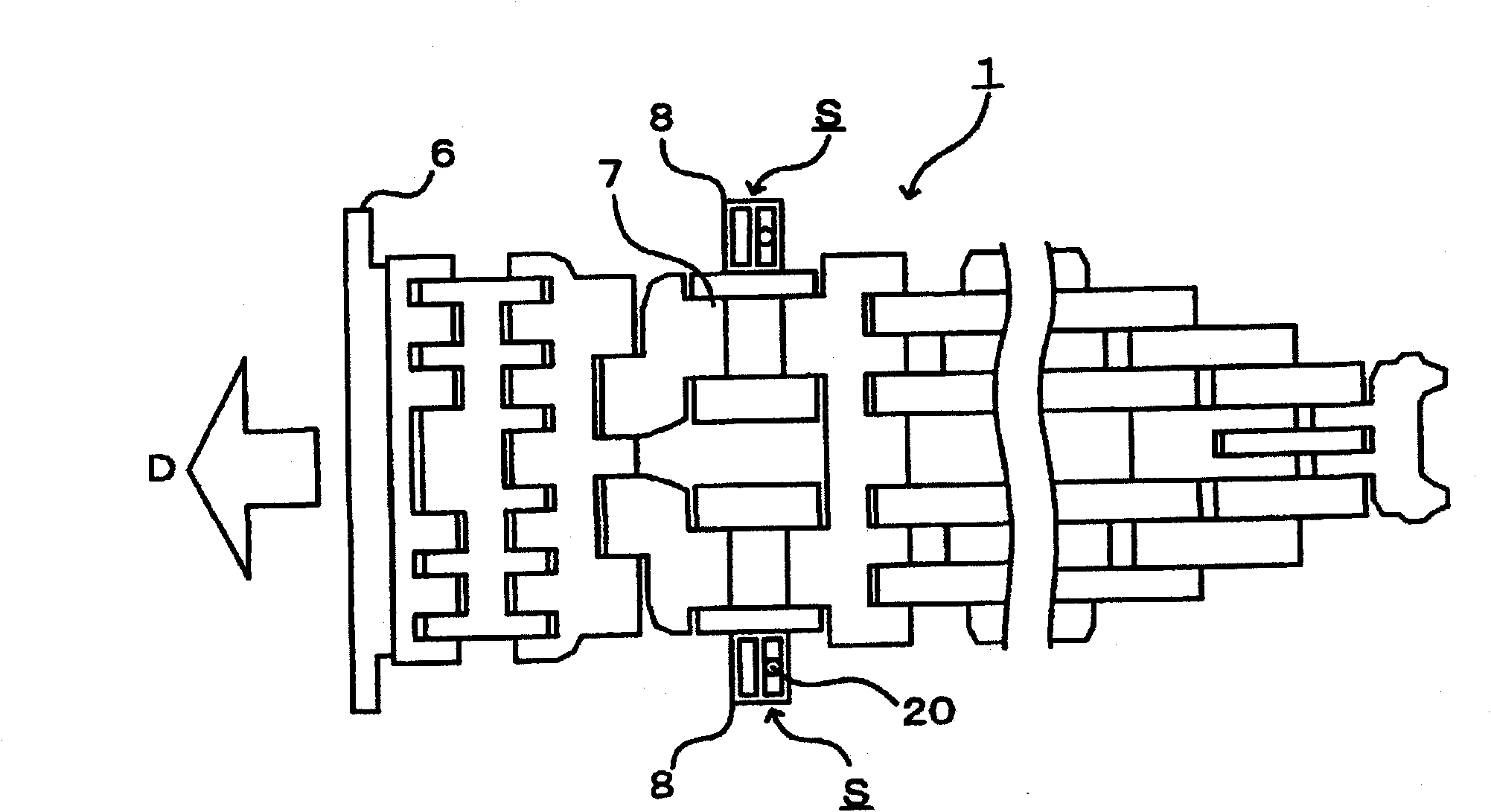

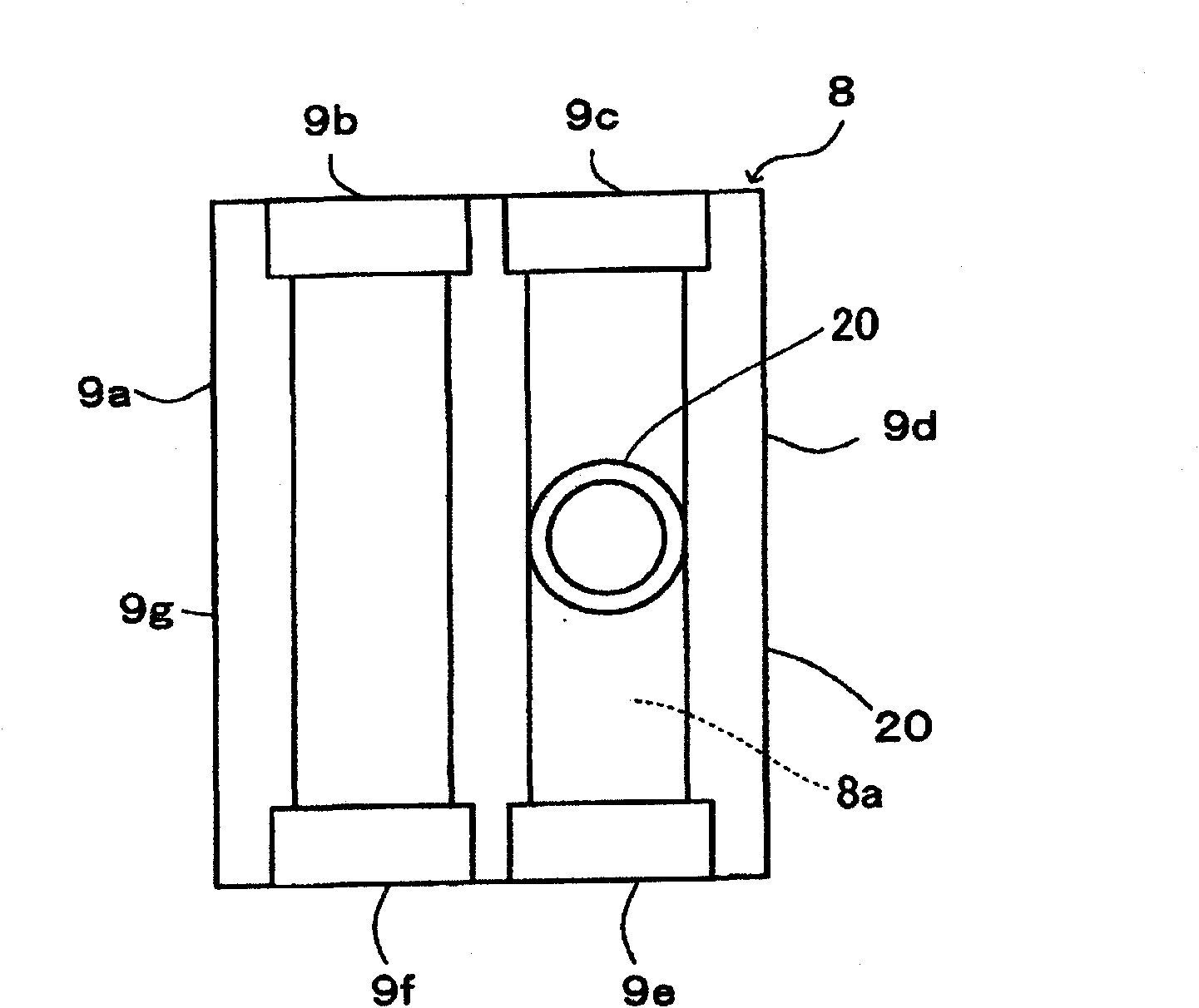

[0087] figure 2 The bottom surface of the dummy bar 1 on which the above-mentioned roll gap measuring device is mounted is shown. In the present embodiment, a pair of sensor blocks 8 provided near both ends in the width direction of the sensor link 7 disposed on the dummy bar head 6 side of the dummy bar 1, that is, on the front side in the conveying direction of the continuous casting machine, Respectively, be provided with the roller interval measuring device S (in figure 2 The illustration of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com