Ultrasonic probe, method for manufacturing the same and ultrasonic diagnostic device

A manufacturing method and ultrasonic technology, applied in the directions of ultrasonic/sonic/infrasonic diagnosis, sonic diagnosis, infrasonic diagnosis, etc., can solve the problems of incomplete function of cMUT chip, incomplete function of ultrasonic transmission and reception, etc., to prevent functional failure. full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0077] Below, refer to Figure 5 and Figure 6 , to describe the first embodiment.

[0078] (3-1. Components of the ultrasonic probe 2)

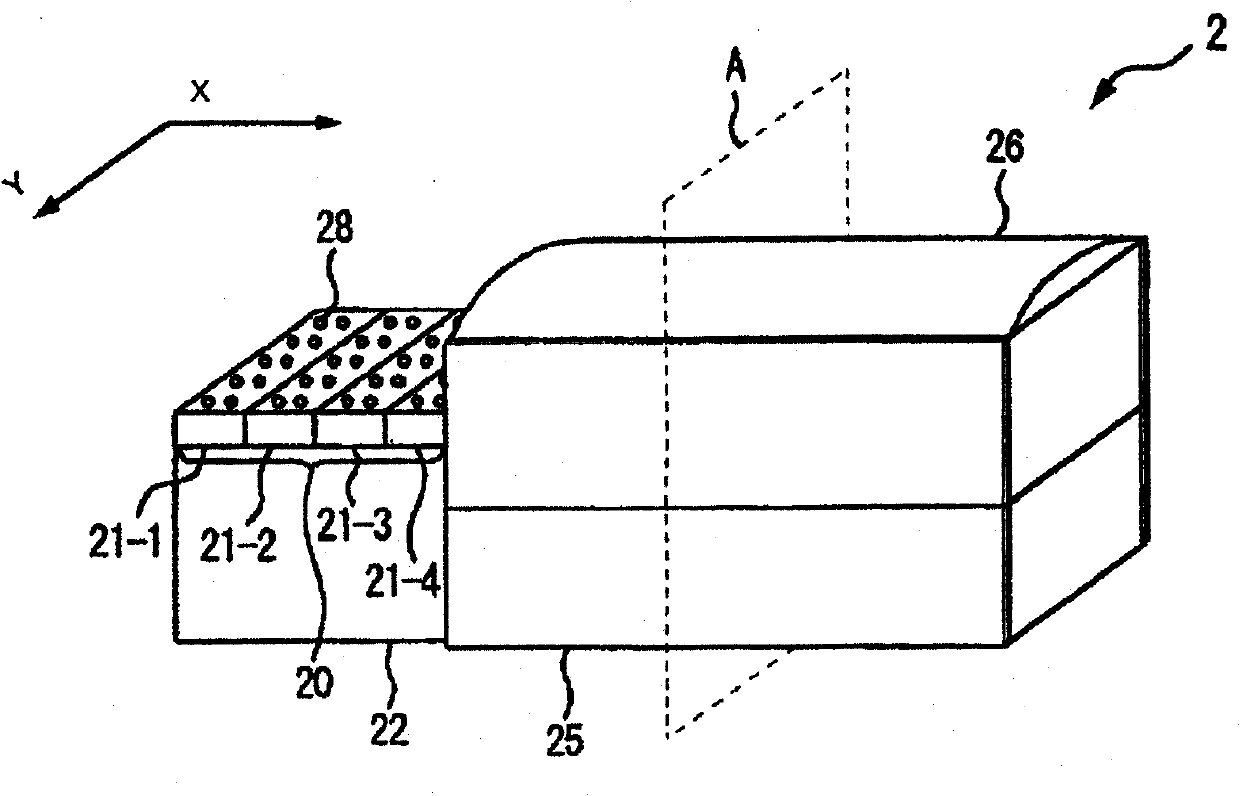

[0079] Figure 5 It is a schematic diagram showing the ultrasonic probe 2 of the first embodiment. Figure 5 yes figure 2 Plane A sectional view of the ultrasonic probe 2.

[0080] A conductive film 76 is formed along the ultrasonic radiation surface of the cMUT chip 20 , the side surfaces of the flexible substrate 72 and the support layer 22 , and an insulating film 78 as an insulating layer is formed on the inner surface of the acoustic lens 26 . The conductive film 76 and the insulating film 78 are formed by, for example, vacuum evaporation, sputtering, or CVD. The conductive film 76 is a Cu or Al film or the like, and has electrical conductivity. The insulating film 78 is bonded to the conductive film 76 by an adhesive. The insulating film 78 is, for example, a silicon oxide film, a paraxylene film, or the like, and has chemical ...

no. 5 approach

[0141] Below, refer to Figure 11 and Figure 12 , and the fifth embodiment will be described. The fifth embodiment relates to electrical connection between the cMUT chip 20 and the flexible substrate 72 .

[0142] Figure 11 It is a schematic diagram showing the ultrasonic probe 2f of the fifth embodiment. Figure 11 and figure 2 The plane A sectional view of is comparable.

[0143] Figure 12 yes Figure 11 A detailed view of the electrical connections.

[0144] In the first embodiment, it was described that the flexible substrate 72 and the cMUT chip 20 are electrically connected via the wire 86 according to the wire bonding method, but in the fifth embodiment, the flexible substrate 72 and the cMUT chip are connected via the through hole 161 or the through hole 171 The cMUT chip 20 is electrically connected.

[0145] The signal pattern of the flexible substrate 72 is electrically connected to the electrodes of the cMUT chip 20 on the rear surface of the periphera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com