Mixed light type light emitting diode packaging structure capable of increasing color rendering and brightness

A technology for light-emitting diodes and packaging structures, applied in electrical components, electrical solid-state devices, circuits, etc., can solve problems such as environmental pollution, and achieve the effects of improving luminous efficiency, color rendering and brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

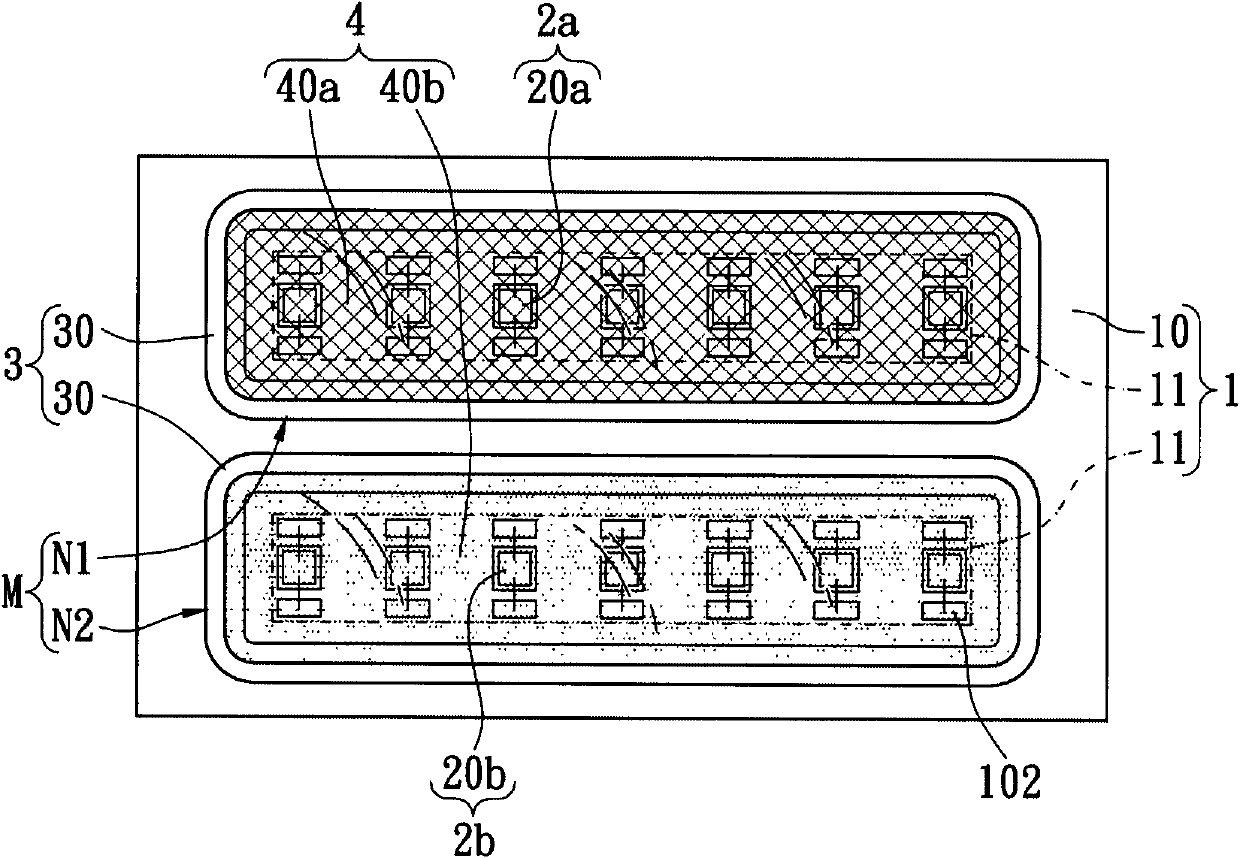

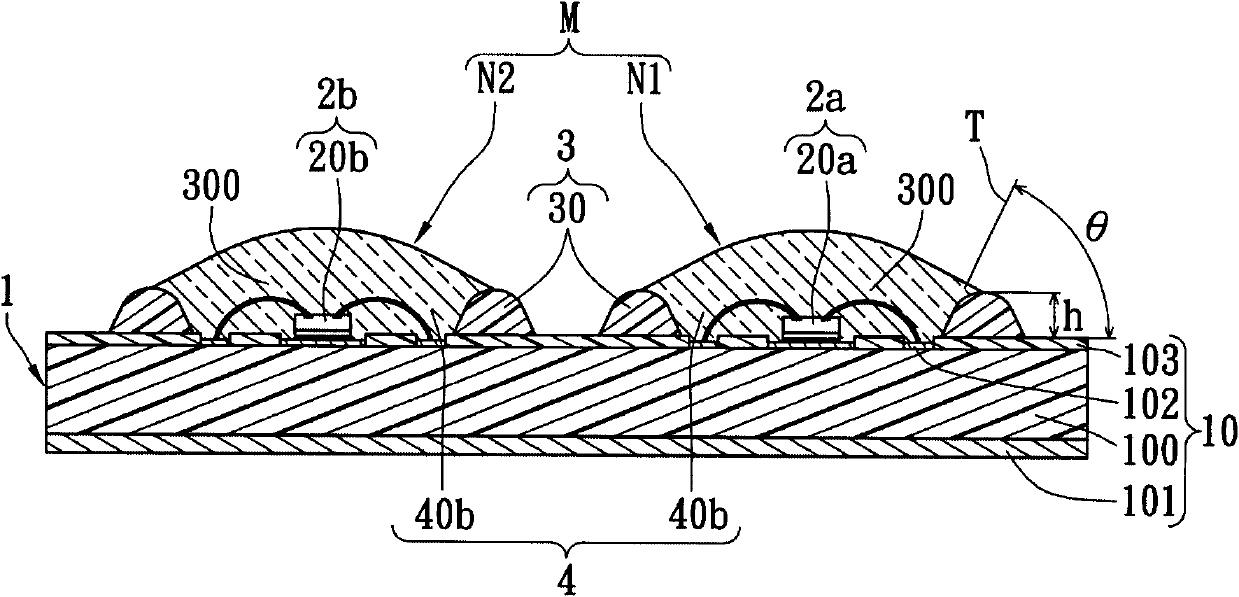

Image

Examples

no. 1 example

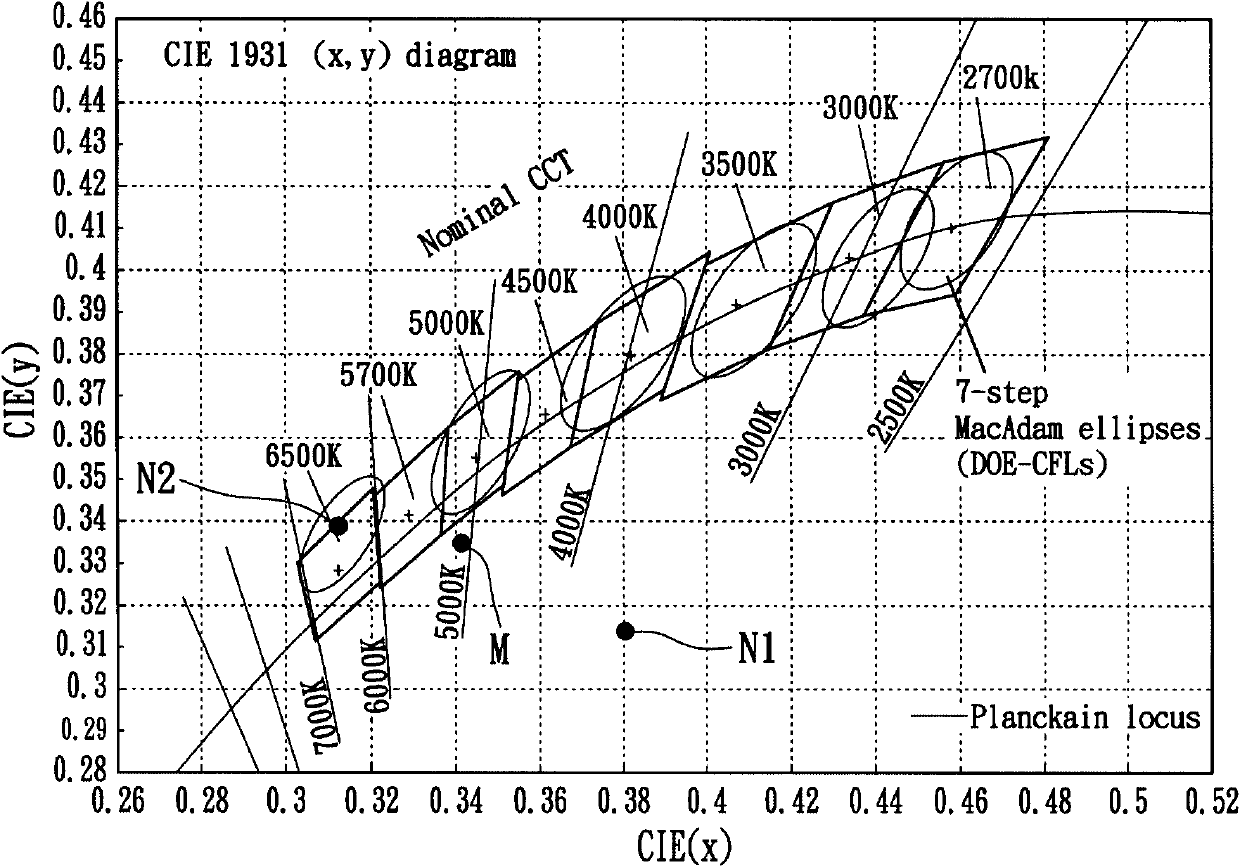

[0068] The following table shows the first group of light-emitting structures N1 (3500K), the second group of light-emitting structures N2 (6500K), and the light-mixing light-emitting diode packaging structure M (3500K+ 6500K) related measurement data of the light source produced:

[0069] group

N1

N2

M

110.457

184.166

156.138

Luminous efficiency

46.01

77.1

69.24

CIE x

0.3799

0.3118

0.3407

CIE y

0.3137

0.3388

0.3345

relative color temperature

3390.4

6478.9

5125.2

Color rendering

82.543

75.893

83.142

[0070] Among them, the unit of relative color temperature (Correlated Color Temperature, CCT) is K (kelvin); the unit of luminous flux (Luminous Flux) is lumen (Lumen); CIE x and CIE y are CIE (International Commission on Illumination, International Commission on Illumination) xy The x and y coordinates of...

no. 3 example

[0079] The following table shows the first group of light-emitting structures N1 (3500K), the second group of light-emitting structures (6500K) N2, and five groups of light-mixing light-emitting diode packaging structures (M1 Relevant measurement data of the light source generated to M5) (3500K+6500K):

[0080] group

N1

N2

M1

M2

M3

M4

M5

105.68

146.44

124.10

122.60

130.72

143.25

112.60

[0081] Luminous efficiency

43.745

60.544

51.316

49.884

53.496

59.199

46.686

CIE x

0.381

0.311

0.367

0.367

0.362

0.351

0.343

CIE y

0.338

0.344

0.381

0.374

0.374

0.374

0.323

relative color temperature

3644.7

6509.9

4418.1

4379.9

4528.8

4887.3

4987.1

Color rendering

81.206

77.290

78.559

78.606

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com