Heater structure of magnetron injection gun

A technology of magnetron injection and electron gun, which is applied in the microwave field to achieve the effect of simple processing technology, not easy to short circuit, and high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] specific implementation plan

[0016] In order to help a better understanding of the present invention, specific embodiments of the present invention will be described below with reference to the accompanying drawings.

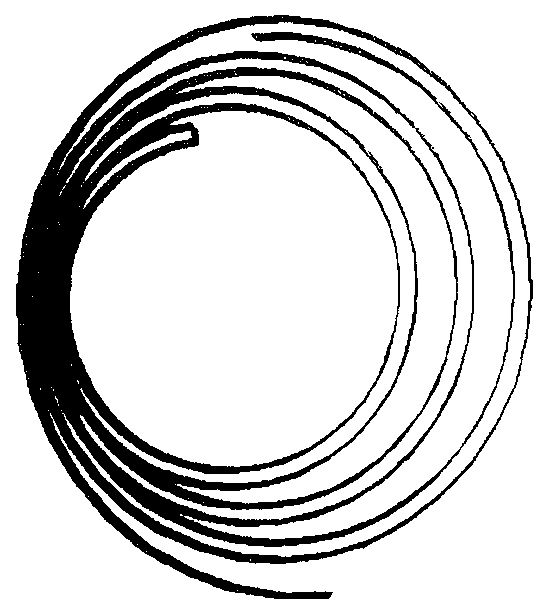

[0017] FIG. 1 is a thermon structure of a conventional magnetron injection electron gun, and the shape of the thermon structure is a truncated circular double helix structure.

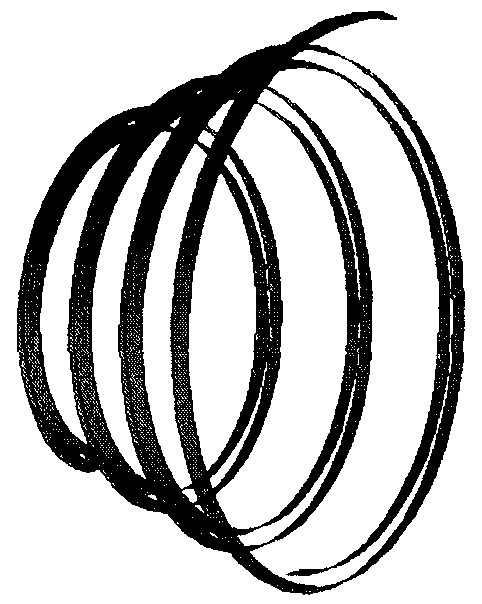

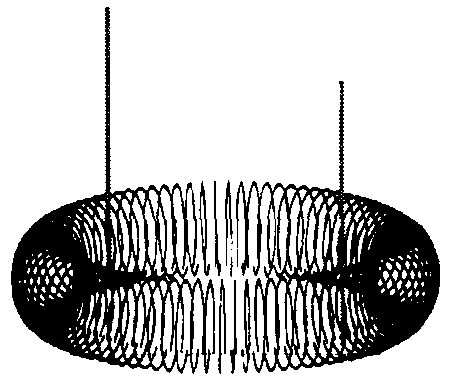

[0018] Figure 2A , Figure 2B , Figure 3A , Figure 3B It is a thermal substructure of a magnetron injection electron gun of the present invention.

[0019] The conventional frusto-conical double-helical thermal substructure (shown in Figure 1) is changed into a circular helical thermal substructure ( Figure 2A , Figure 2B , Figure 3A , Figure 3B Shown), this can increase the length of the heater winding wire (usually tungsten wire or rhenium tungsten wire), thereby increasing the resistance of the heater and achieving the purpose of increasing the heating power of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com